Feeling lost in a sea of interview questions? Landed that dream interview for Plastic Molder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plastic Molder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

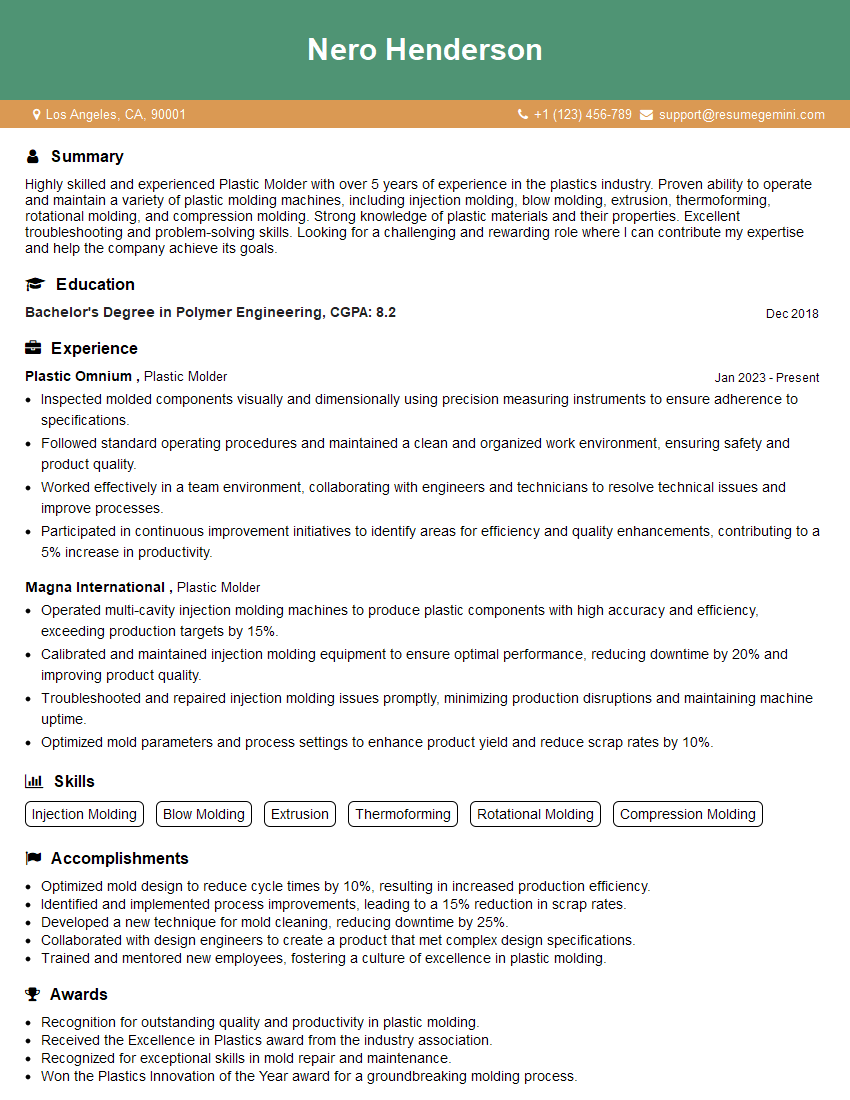

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Molder

1. What are the different types of plastic molding processes?

- Injection Molding

- Blow Molding

- Extrusion Molding

- Compression Molding

- Transfer Molding

2. What are the key factors to consider when selecting a plastic molding process?

Material Properties

- Melt Flow Index (MFI)

- Glass Transition Temperature (Tg)

- Crystallinity

Part Geometry

- Size and Shape

- Wall Thickness

- Ribs and Bosses

Production Volume

- Number of Parts Required

- Cycle Time

Cost

- Mold Cost

- Material Cost

- Labor Cost

3. What are the common defects that can occur in plastic molding?

- Warping

- Sinking

- Flash

- Voids

- Bubbles

4. How can you troubleshoot common defects in plastic molding?

- Identify the Cause of the Defect

- Adjust Process Parameters

- Modify Mold Design

- Change Material Formulation

5. What are the different types of molds used in plastic molding?

- Two-Plate Mold

- Three-Plate Mold

- Hot Runner Mold

- Cold Runner Mold

6. What are the advantages and disadvantages of using different types of molds?

Two-Plate Mold

Advantages:

- Simple Design

- Low Cost

Disadvantages:

- Flash

- Cycle Time

Three-Plate Mold

Advantages:

- No Flash

- Faster Cycle Time

Disadvantages:

- Higher Cost

- More Complex Design

Hot Runner Mold

Advantages:

- No Runners

- Faster Cycle Time

- Material Savings

Disadvantages:

- Higher Cost

- More Complex Design

Cold Runner Mold

Advantages:

- Lower Cost

- Simpler Design

Disadvantages:

- Runners

- Longer Cycle Time

- Material Waste

7. What are the different types of plastic materials used in molding?

- Thermoplastics

- Thermosets

8. What are the properties of different plastic materials?

- Strength

- Stiffness

- Toughness

- Melting Point

- Glass Transition Temperature

9. How do you select the right plastic material for a particular application?

- Consider the Requirements of the Application

- Research Different Plastic Materials

- Test Different Materials

10. What are the latest trends in plastic molding?

- Additive Manufacturing

- In-Mold Decoration

- Lightweighting

- Sustainability

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Molders are responsible for operating and maintaining machinery that shapes plastic materials into various forms. Their key duties include:

1. Equipment Operation

Operate injection molding, blow molding, or other plastic molding equipment to produce plastic parts or products.

- Set up and adjust molding machines according to specifications.

- Monitor the molding process and make adjustments as needed.

- Inspect finished products for quality and defects.

2. Production Optimization

Analyze production processes to identify and implement improvements.

- Troubleshoot and resolve equipment malfunctions.

- Suggest modifications to molds and machinery to enhance efficiency.

- Maintain a clean and organized work area.

3. Quality Assurance

Conduct inspections and tests to ensure products meet quality standards.

- Follow quality control procedures and specifications.

- Record and report quality data.

- Identify and address potential quality issues.

4. Safety Compliance

Follow established safety protocols and regulations.

- Wear appropriate personal protective equipment (PPE).

- Handle and store chemicals and hazardous materials safely.

- Maintain a safe and ergonomic work environment.

Interview Tips

To ace the interview, candidates should:

1. Research the Company and Position

Gather information about the company’s products, services, and industry.

- Review the job description thoroughly.

- Identify the key skills and experience required.

2. Practice Answering Common Interview Questions

Prepare for questions about your experience, qualifications, and how you can contribute to the company.

- Use the STAR method (Situation, Task, Action, Result) to provide clear and concise examples.

- Highlight your technical skills, such as proficiency in operating different molding equipment.

3. Emphasize Quality and Safety

Demonstrate your commitment to producing high-quality products and maintaining a safe work environment.

- Share examples of how you have implemented quality control measures.

- Describe your experience in following safety procedures and regulations.

4. Ask Relevant Questions

Show interest and engagement by asking thoughtful questions about the company, the position, and the industry.

- Inquire about the company’s future plans and growth prospects.

- Ask about opportunities for professional development and advancement.

Next Step:

Now that you’re armed with the knowledge of Plastic Molder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plastic Molder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini