Are you gearing up for an interview for a Plastic Molding Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Plastic Molding Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

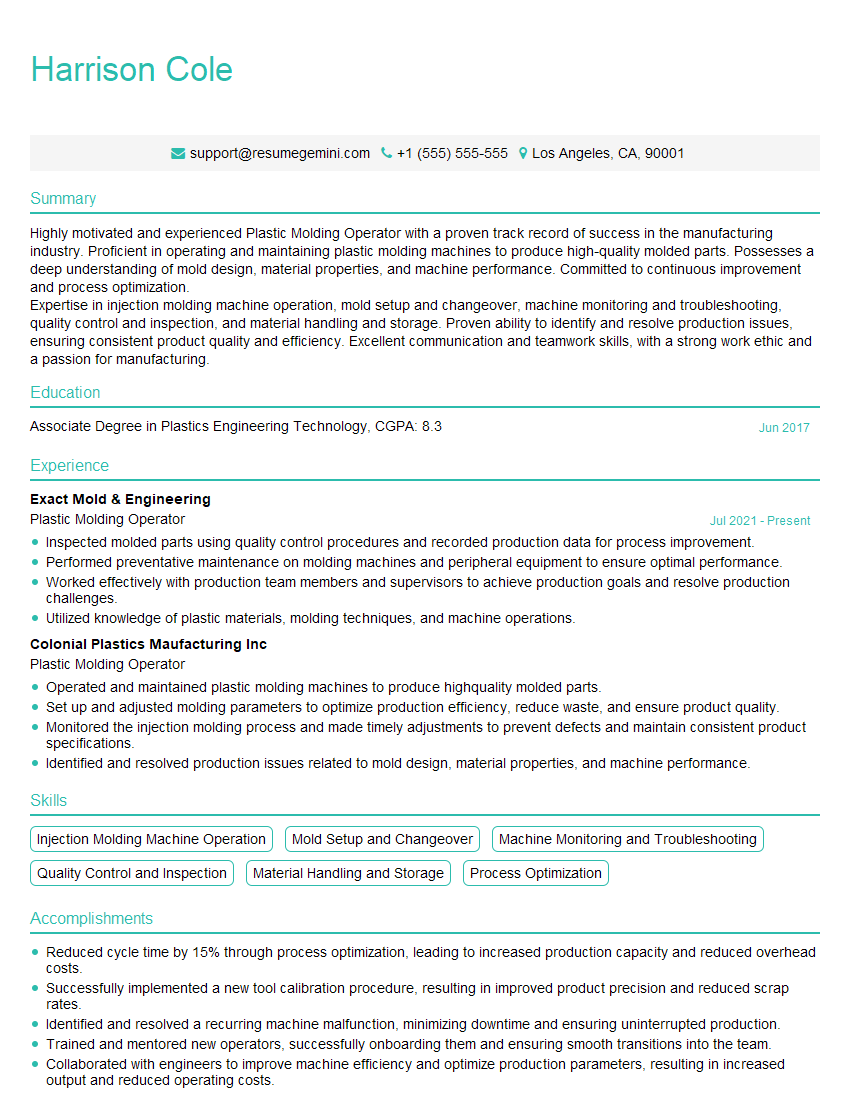

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Molding Operator

1. What are the different types of plastic molding processes?

There are various plastic molding processes, including:

- Injection Molding: Molten plastic is injected into a mold cavity under high pressure.

- Blow Molding: A tube of molten plastic is expanded using compressed air to form a hollow shape.

- Compression Molding: Plastic is heated and placed in a heated mold, which is then closed to form the product.

- Extrusion: Molten plastic is forced through a shaped die to form a continuous product, such as pipes or sheets.

- Thermoforming: Plastic sheets are heated and then formed over a mold using pressure or vacuum.

2. Describe the key parameters involved in injection molding and how they affect the molding process?

Mold Temperature

- Controls the cooling and solidification of the plastic, affecting part dimensions, surface finish, and strength.

Injection Pressure

- Fills the mold cavity and influences part weight, density, and warpage.

Injection Speed

- Affects the flow of plastic into the mold, influencing part surface quality and the potential for defects.

Hold Pressure and Time

- Compensates for material shrinkage, ensuring adequate part density and preventing voids.

3. What are the different types of plastic materials used in molding, and how do their properties impact the molding process?

Common plastic materials include:

- Polyethylene (PE): Flexible, low strength, resistant to chemicals.

- Polypropylene (PP): Strong, rigid, good chemical resistance.

- Polyvinyl Chloride (PVC): Rigid, durable, fire retardant.

- Acrylonitrile Butadiene Styrene (ABS): Tough, lightweight, good impact resistance.

- Polyethylene Terephthalate (PET): Clear, strong, shatter-resistant.

Properties impact molding

- Melting Point: Determines the temperature required for molding.

- Flowability: Affects the ability of the plastic to fill the mold cavity.

- Shrinkage: Occurs during cooling and must be compensated for in mold design.

- Strength and Toughness: Influence the durability of the molded part.

4. How do you troubleshoot common molding defects, such as flash, sink marks, and warpage?

Flash

- Overfilling of the mold cavity due to excessive injection pressure or mold misalignment.

- Solution: Adjust injection pressure, check mold alignment, or inspect for damaged mold components.

Sink Marks

- Depressions in the part due to localized material shrinkage.

- Solution: Increase injection pressure, add cooling channels to the mold, or optimize mold temperature.

Warpage

- Distortion of the part due to uneven cooling or internal stresses.

- Solution: Modify mold design for uniform cooling, adjust process parameters (e.g., injection speed, cooling time), or consider mold coatings.

5. What maintenance procedures are essential for plastic molding equipment, and how often should they be performed?

Regular maintenance includes:

- Mold Cleaning: Remove plastic residue, debris, and release agents to ensure proper part release and surface quality.

- Machine Inspection: Check for wear and tear on moving parts, leaks, and electrical connections.

- Hydraulic System Maintenance: Change hydraulic fluids, clean filters, and inspect hoses and pumps.

- Calibration: Verify the accuracy of temperature sensors, pressure gauges, and other critical instrumentation.

Frequency

- Mold Cleaning: Daily or as needed.

- Machine Inspection: Weekly.

- Hydraulic System Maintenance: Monthly or as per manufacturer recommendations.

- Calibration: As recommended by the equipment manufacturer.

6. How do you ensure the quality of plastic molded parts, and what quality control techniques do you employ?

Quality control measures include:

- Dimensional Inspection: Verify part dimensions and tolerances using calipers, micrometers, or CMMs.

- Visual Inspection: Check for surface defects, color variations, and other cosmetic issues.

- Functional Testing: Test the functionality and performance of the part in real-world applications.

- Incoming Material Inspection: Verify the quality of incoming plastic materials before molding.

7. What is the role of automation in plastic molding, and how can it improve efficiency and productivity?

- Automated Molding Machines: Use robotic arms or other automation systems to handle mold opening/closing, part ejection, and material feeding.

- Process Monitoring Systems: Collect and analyze data on process parameters, providing real-time feedback and control.

- Defect Detection Systems: Use cameras, sensors, or other technologies to detect and reject defective parts.

Benefits

- Increased output and reduced lead times.

- Improved quality and consistency.

- Reduced labor costs and improved workplace safety.

8. Describe your experience in operating and maintaining plastic molding equipment.

- Managed a team of operators responsible for operating and maintaining a fleet of injection molding machines.

- Successfully diagnosed and resolved complex equipment issues, maximizing uptime and production efficiency.

- Implemented process improvements and quality control measures that resulted in significant reduction in defects and customer complaints.

9. What are your strengths and weaknesses as a Plastic Molding Operator?

Strengths- Excellent understanding of plastic molding processes and equipment.

- Proven ability to operate and troubleshoot injection molding machines.

- Attention to detail and commitment to quality.

- Strong problem-solving and analytical skills.

- Limited experience in extrusion molding.

- Seeking opportunities to enhance my knowledge of mold design and engineering.

10. What are your career goals and how do you see this role contributing to them?

- Aspire to become a Production Supervisor in the plastics industry.

- Believe that this role will provide me with the necessary experience in managing and optimizing molding operations.

- Excited about the opportunity to lead a team, improve processes, and contribute to the company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Molding Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Molding Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Molding Operators are responsible for operating and maintaining plastic molding machines to produce plastic components and products. They play a crucial role in ensuring the efficient and high-quality production of plastic parts.

1. Machine Operation and Maintenance

Plastic Molding Operators are responsible for setting up, operating, and maintaining plastic molding machines. This involves:

- Loading and unloading raw materials

- Monitoring machine operation and making adjustments as needed

- Performing routine maintenance and troubleshooting

- Ensuring that machines are operating safely and efficiently

2. Quality Control

Plastic Molding Operators are responsible for ensuring that the plastic components produced meet the required quality standards. This involves:

- Inspecting finished products for defects

- Making adjustments to the molding process as needed

- Following quality control procedures

- Keeping records of quality inspections

3. Production Planning

Plastic Molding Operators may also be involved in production planning and scheduling. This involves:

- Working with engineers and production managers to determine production schedules

- Estimating production times

- Ordering raw materials

- Ensuring that production goals are met

4. Safety and Environmental Compliance

Plastic Molding Operators must follow all safety and environmental regulations. This involves:

- Using proper safety equipment

- Following lockout/tagout procedures

- Handling hazardous materials properly

- Complying with environmental regulations

Interview Tips

Preparing for an interview for a Plastic Molding Operator position can help you increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, goals, and the requirements of the job. You can find information on the company’s website, social media pages, and industry news articles.

- Example: You can learn about the company’s history, mission statement, and recent accomplishments.

- Example: You can also learn about the specific requirements of the Plastic Molding Operator position, such as the types of machines you will be operating and the quality standards you will be expected to meet.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver clear and concise responses during the interview.

- Example: For the question “Tell me about yourself,” you can prepare a brief summary of your experience and skills that are relevant to the Plastic Molding Operator position.

- Example: For the question “Why are you interested in this position,” you can explain why you are interested in working for the company and how your skills and experience match the requirements of the job.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Plastic Molding Operator position. This includes your experience operating and maintaining plastic molding machines, your quality control experience, and your knowledge of safety and environmental regulations.

- Example: You can provide specific examples of times when you have successfully operated and maintained plastic molding machines.

- Example: You can also provide examples of times when you have identified and resolved quality issues.

4. Ask Questions

Asking questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include:

- Example: “What is the company’s culture like?”

- Example: “What are the opportunities for advancement within the company?”

- Example: “What are the biggest challenges facing the company right now?”

Next Step:

Now that you’re armed with the knowledge of Plastic Molding Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plastic Molding Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini