Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plastic Numerical Tool and Process Control Programmer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plastic Numerical Tool and Process Control Programmer so you can tailor your answers to impress potential employers.

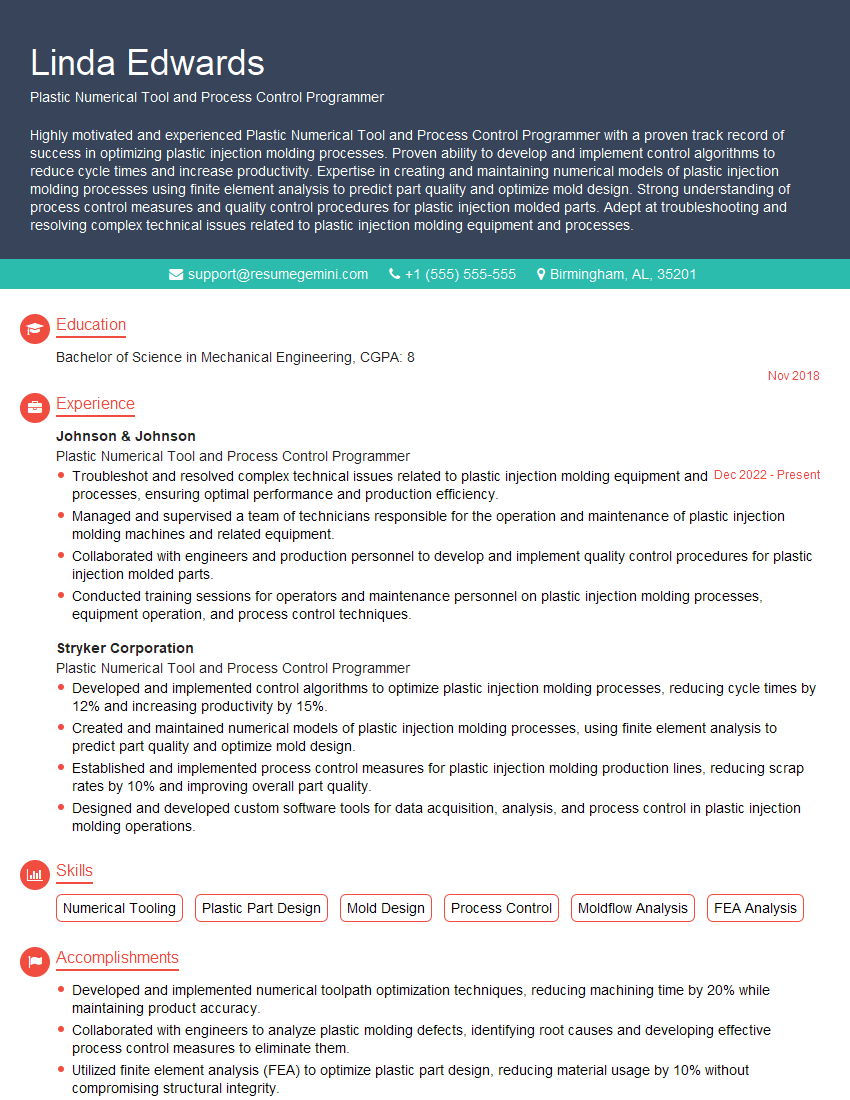

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Numerical Tool and Process Control Programmer

1. What is the role of a Plastic Numerical Tool and Process Control Programmer?

As a Plastic Numerical Tool and Process Control Programmer, my primary responsibilities include:

- Programming and operating numerical control (NC) machines and robots used in the production of plastic parts

- Developing and maintaining NC programs, including tool path generation, feed rates, and other machining parameters

- Setting up and calibrating NC machines and robots to ensure optimal performance

- Troubleshooting and resolving any technical issues that arise during the production process

- Continuously improving processes to enhance efficiency and quality

2. Explain the CAM software you have experience with?

I have extensive experience with various CAM software packages, including:

- Mastercam

- SolidCAM

- NX CAM

- PowerMill

I am proficient in using these software to create tool paths, simulate machining processes, and generate NC programs.

3. What is your approach to optimizing NC programs for efficiency and quality?

- I start by analyzing the part geometry and identifying the critical features that require high precision

- I then select the appropriate cutting tools and tool path strategies to achieve the desired surface finish and tolerances

- I use simulation software to verify the tool paths and identify any potential issues or areas for improvement

- Finally, I optimize feed rates and spindle speeds to minimize cycle time while maintaining part quality

4. How do you ensure the accuracy and reliability of NC programs?

- I follow a rigorous process of testing and validation before implementing any NC program

- I use simulation software to detect any errors in the tool paths or NC code

- I perform physical dry runs to verify the program’s accuracy and identify any potential collisions

- I also regularly monitor the production process to ensure that parts are being produced within specified tolerances

5. Describe your experience with plastic molding processes?

I have a solid understanding of plastic molding processes, including injection molding, blow molding, and thermoforming.

- I am familiar with the different types of plastic materials and their properties

- I can identify and troubleshoot common molding defects

- I have experience in designing and optimizing mold tools for plastic parts

6. What are the key considerations for setting up and calibrating NC machines and robots?

- Ensure that the machine is level and properly aligned

- Calibrate the axes of the machine to achieve high accuracy and precision

- Set the appropriate feed rates and spindle speeds for the specific machining operation

- Program the machine to perform the desired tool paths and operations

- Verify the accuracy of the machine setup through test runs and measurements

7. How do you troubleshoot and resolve technical issues that arise during the production process?

- I start by identifying the source of the problem, whether it is mechanical, electrical, or software-related

- I then use my knowledge of the machine and the NC program to identify potential solutions

- I perform tests and make adjustments to resolve the issue

- I also consult with colleagues and technical support resources if necessary

8. What are your strategies for continuously improving processes to enhance efficiency and quality?

- I regularly analyze production data to identify areas for improvement

- I work with other team members to implement process changes and enhancements

- I stay up-to-date with the latest industry best practices and technologies

- I am always looking for ways to streamline processes and reduce waste

9. Describe your experience with quality control and inspection techniques for plastic parts?

- I am familiar with various quality control and inspection techniques, including dimensional measurements, surface finish analysis, and visual inspection

- I use specialized equipment such as CMMs, profilometers, and microscopes to ensure that parts meet the required specifications

- I also work closely with quality control personnel to develop and implement quality control procedures

10. How do you stay abreast of the latest advancements in plastic numerical tool and process control programming?

- I attend industry conferences and workshops

- I read trade publications and technical journals

- I participate in online forums and discussion groups

- I seek out opportunities for professional development

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Numerical Tool and Process Control Programmer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Numerical Tool and Process Control Programmer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plastic Numerical Tool and Process Control Programmer plays a critical role in designing, implementing, and maintaining numerical control programs that automate and optimize plastic injection molding processes.

1. Numerical Control Programming

Develop and maintain numerical control (NC) programs for computer-controlled plastic injection molding machines.

- Convert product designs into machine-readable NC code.

- Optimize NC programs for efficiency and precision.

- Troubleshoot and debug program errors.

2. Process Control Optimization

Monitor and control plastic injection molding processes to ensure optimal quality and efficiency.

- Adjust process parameters (e.g., temperature, pressure, cycle time) to improve product quality.

- Develop and implement quality control procedures.

- Analyze production data and identify areas for process improvements.

3. Equipment Maintenance and Troubleshooting

Maintain and troubleshoot plastic injection molding equipment to ensure smooth operation.

- Perform routine maintenance and calibration tasks.

- Diagnose and repair equipment breakdowns.

- Collaborate with engineering and maintenance teams to resolve complex issues.

4. Quality Assurance

Ensure the quality of plastic injection molded products by adhering to established standards and specifications.

- Perform product inspections and testing.

- Identify and resolve quality issues.

- Develop and implement quality improvement initiatives.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success.

1. Research the Company and Industry

Familiarize yourself with the company’s history, products/services, and industry trends.

- Visit the company website and LinkedIn page.

- Read industry publications and news articles.

2. Practice Your Answers

Prepare thoughtful answers to common interview questions, highlighting your relevant skills and experience.

- Start with the STAR method (Situation, Task, Action, Result) to structure your answers.

- Use specific examples and quantify your accomplishments whenever possible.

3. Highlight Your Technical Expertise

Emphasize your proficiency in NC programming, process control, and equipment maintenance.

- Discuss your experience with different types of plastic injection molding machines.

- Showcase your ability to troubleshoot and resolve technical challenges.

4. Demonstrate Your Problem-Solving Skills

Interviewers often ask problem-solving questions to assess your critical thinking and analytical abilities.

- Describe a complex problem you solved in a previous role.

- Explain your thought process and how you arrived at a solution.

5. Show Your Passion for the Industry

Express your enthusiasm for the plastics industry and your commitment to continuous learning.

- Share your knowledge of emerging trends and technologies.

- Discuss your professional development goals and aspirations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plastic Numerical Tool and Process Control Programmer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!