Are you gearing up for an interview for a Plastic Patternmaker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Plastic Patternmaker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

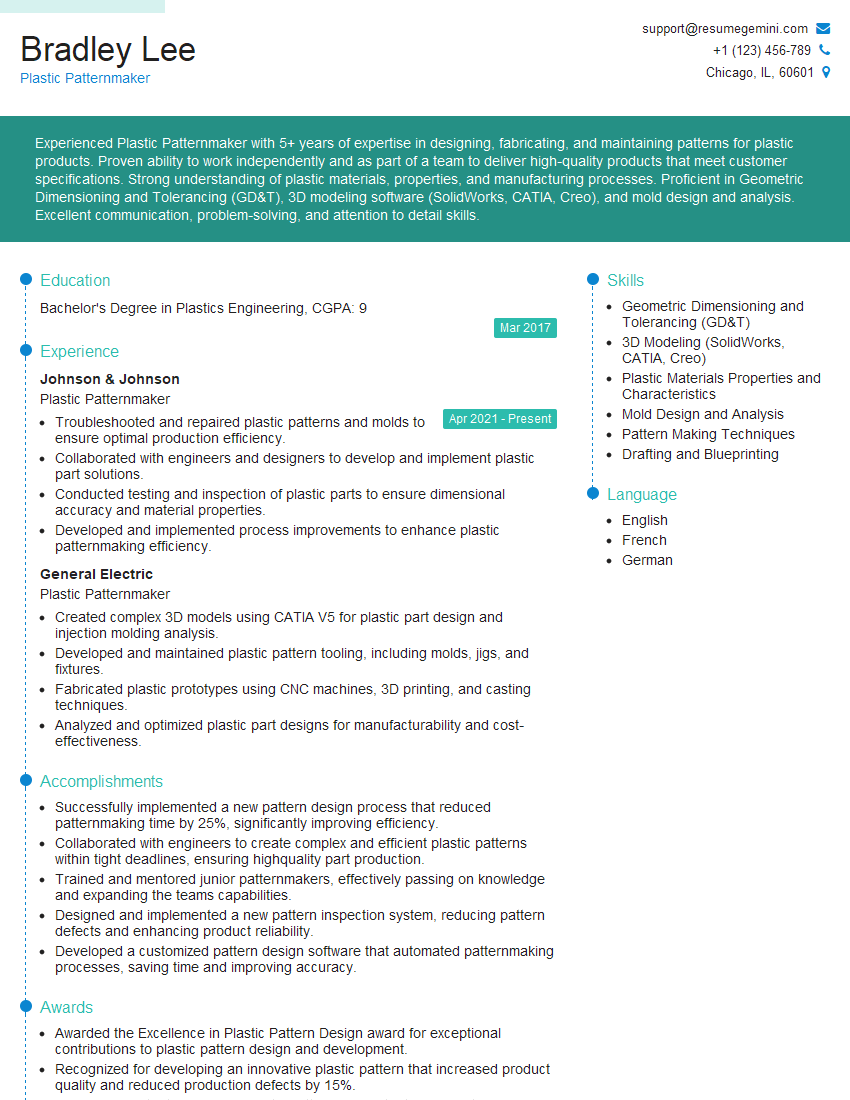

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Patternmaker

1. What are the different types of plastic patternmaking processes?

- Hand lay-up

- Vacuum forming

- Compression molding

2. What are the key considerations when designing a plastic pattern?

- The type of plastic being used

- The shape and complexity of the part

- The production method

3. What are the different types of materials used in plastic patternmaking?

- Wood

- Metal

- Plastic

4. What are the different types of tools used in plastic patternmaking?

- Saws

- Sanders

- Routers

5. What are the safety precautions that must be taken when working with plastic patterns?

- Wear appropriate safety gear

- Use sharp tools

- Be aware of your surroundings

6. What are the quality control checks that must be performed on plastic patterns?

- Visual inspection

- Dimensional inspection

- Material testing

7. What are the challenges of plastic patternmaking?

- Working with different types of materials

- Creating complex shapes

- Meeting tight deadlines

8. What are the rewards of plastic patternmaking?

- Seeing your work come to life

- Making a difference in the manufacturing process

- Learning new skills

9. What are the career opportunities for plastic patternmakers?

- Patternmaker

- Mold maker

- Product designer

10. What are the key skills that a plastic patternmaker needs?

- Strong attention to detail

- Excellent communication skills

- Ability to work independently and as part of a team

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Patternmaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Patternmaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Patternmakers are highly skilled professionals who design and build physical models (patterns) used to create molds for plastic products.

1. Pattern Design

Work with engineers and designers to determine the shape and dimensions of the plastic parts.

- Analyze design specifications and create technical drawings using CAD software.

- Determine the most efficient and cost-effective methods for pattern construction.

2. Pattern Construction

Build physical patterns according to the design specifications.

- Select and prepare materials such as wood, metal, or plastic.

- Use hand and power tools to shape and assemble the pattern components.

3. Mold and Core Making

Collaborate with moldmakers to create molds and cores from the patterns.

- Review mold designs and provide feedback on pattern modifications.

- Inspect finished molds and cores to ensure accuracy and functionality.

4. Quality Control

Ensure the patterns, molds, and plastic products meet quality standards.

- Conduct dimensional inspections and compare results to specifications.

- Identify and resolve any defects or inconsistencies.

Interview Tips

Preparing thoroughly for a Plastic Patternmaker interview will increase your chances of success.

1. Research the Company and Position

Gain a deep understanding of the company’s history, products, and culture.

- Review the job description carefully and identify the key requirements.

- Research the industry and current trends in plastic patternmaking.

2. Showcase Your Technical Skills

Highlight your proficiency in CAD software, pattern design, and construction techniques.

- Provide specific examples of complex patterns you have designed and built.

- Discuss your experience with different materials and manufacturing processes.

3. Emphasize Quality and Precision

Patternmakers play a critical role in ensuring the accuracy and quality of plastic products.

- Describe your commitment to precision and attention to detail.

- Explain your quality control procedures and how you ensure that patterns meet specifications.

4. Teamwork and Communication

Plastic Patternmakers often work as part of a team.

- Emphasize your ability to collaborate with engineers, designers, and moldmakers.

- Provide examples of how you effectively communicate technical information.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plastic Patternmaker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plastic Patternmaker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.