Are you gearing up for a career in Plastic Printer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Plastic Printer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

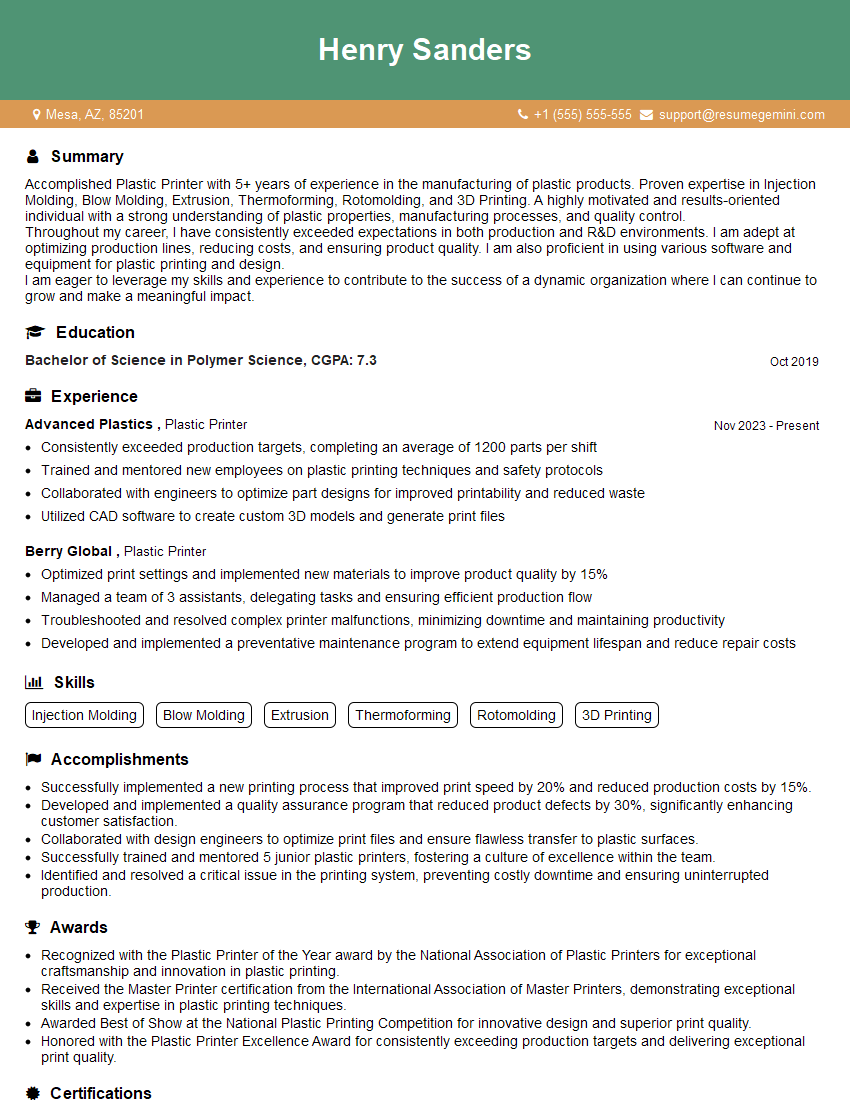

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Printer

1. What are the different types of plastic printing methods? Describe the pros and cons of each.

- Screen printing: Pros: Durable, cost-effective for short runs. Cons: Not suitable for complex designs or gradients.

- Pad printing: Pros: Versatile, can print on complex shapes. Cons: Slow, not suitable for large prints.

- Digital printing: Pros: High-quality prints, variable data printing. Cons: More expensive than other methods.

- Inkjet printing: Pros: High-resolution prints, suitable for large prints. Cons: Prone to smudging, not durable.

- Laser printing: Pros: Durable, consistent prints. Cons: Not as versatile as other methods, limited color range.

2. What are the key factors to consider when selecting a plastic printing method?

Factors to Consider

- Nature of the plastic: Different plastics have different properties that affect printability.

- Design complexity: Some printing methods are better suited for complex designs than others.

- Production volume: The printing method should be cost-effective for the expected production volume.

- Quality requirements: The printing method should meet the desired quality standards.

- Budget: The cost of the printing method should fit within the budget.

3. What are the common defects in plastic printing and how can they be prevented?

- Smudging: Caused by poor ink adhesion or excessive ink application. Prevented by using appropriate inks and printing techniques.

- Bleeding: Occurs when ink spreads beyond the desired area. Prevented by using sharp printing plates and ensuring proper ink viscosity.

- Ghosting: Light or faint images appearing on the print. Prevented by using high-quality printing materials and controlling ink drying time.

- Tearing: Occurs when the plastic is not properly stretched or heated during printing. Prevented by using the right tension and temperature settings.

- Warping: Occurs when the plastic deforms after printing. Prevented by using a cooling process to stabilize the plastic.

4. What are the latest advancements in plastic printing technology?

- UV LED printing: High-resolution, fast-drying, energy-efficient.

- 3D printing: Enables the creation of complex shapes and structures.

- Digital inkjet printing: Versatile, allows for variable data printing and personalization.

- Advanced curing techniques: Improve ink adhesion and durability.

- Recyclable and sustainable inks: Reduce environmental impact.

5. How do you ensure color accuracy and consistency in plastic printing?

- Color management system: Use a color management system to calibrate and profile equipment.

- Standard operating procedures: Establish and follow standardized printing procedures.

- Color matching: Use color matching tools to ensure accurate reproduction of colors.

- Proofing: Print proofs and compare them to the original artwork to verify color accuracy.

- Regular calibration: Calibrate printing equipment regularly to maintain color consistency.

6. What is the role of pre-treatment in plastic printing?

- Improve ink adhesion: Pre-treatment creates a surface that enhances ink bonding.

- Remove contaminants: Pre-treatment removes oils, dust, and other contaminants that can interfere with printing.

- Increase print durability: Pre-treated plastics resist fading, scratching, and abrasion.

7. How do you choose the right ink for plastic printing?

- Compatibility with plastic: Ensure the ink is compatible with the specific type of plastic being printed.

- Viscosity and flowability: Choose an ink with the right viscosity and flowability for the printing method.

- Drying time: Consider the drying time of the ink to ensure efficient printing.

- Color range and opacity: Select an ink that meets the desired color requirements and opacity.

- Durability and resistance: Choose an ink that is resistant to fading, scratching, and other environmental factors.

8. What is the importance of post-printing processes in plastic printing?

- Curing: Curing processes stabilize the ink and improve its durability and adhesion.

- Coating: Coatings can enhance print quality, protect against UV radiation, and improve scratch resistance.

- Finishing: Finishing processes such as die-cutting, embossing, and foiling add value and aesthetic appeal.

9. How do you handle and store plastic printed products to maintain their quality?

- Proper handling: Wear gloves and avoid touching printed surfaces to prevent smudging.

- Storage conditions: Store printed products in a controlled environment away from direct sunlight, moisture, and temperature extremes.

- Packaging: Use appropriate packaging materials to protect products from damage during storage and transportation.

10. What are the safety precautions to be taken while working with plastic printing equipment?

- Follow operating procedures: Adhere to established safety protocols for equipment operation.

- Wear protective gear: Use gloves, safety glasses, and other protective equipment as required.

- Handle chemicals safely: Store and dispose of chemical products according to safety regulations.

- Maintain clean work area: Keep the work area clean and free of tripping hazards.

- Be aware of potential hazards: Recognize and respond to potential hazards such as electrical shocks, cuts, and burns.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Printer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Printer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Printers are responsible for operating and maintaining plastic printing machines to produce a variety of plastic products, such as packaging, labels, and signs.

1. Prepare Printing Machine

Prior to starting printing, its operator must first prepare the printing machine. Here’s what this preparation involves:

- Loading plastic sheets or rolls into the machine.

- Installing printing plates onto the machine.

- Setting up the machine’s printing parameters.

2. Monitor Printing Process

Once the printing process begins, the operator must monitor it closely to ensure that it runs smoothly and that the products being produced meet quality standards. Monitoring the printing process involves:

- Observing the printing machine’s operation.

- Checking the quality of the printed products.

- Making adjustments to the printing machine as needed.

3. Maintain Printing Equipment

In addition to operating the printing machine, the operator is also responsible for maintaining it. This includes:

- Cleaning the printing machine.

- Inspecting the printing machine for wear and tear.

- Making minor repairs to the printing machine.

4. Troubleshooting Printing Problems

If the printing machine experiences any problems, the operator must be able to troubleshoot the problem and make the necessary repairs. This may involve:

- Identifying the source of the problem.

- Making repairs to the printing machine.

- Restarting the printing process.

Interview Tips

To ace a Plastic Printer interview, it is important to be prepared. Here are some tips:

1. Research the Company and the Job

Plastic printing companies use a variety of printing techniques to produce a range of products.

Some common printing techniques include:

- Flexography: This technique uses flexible printing plates to transfer ink to a substrate.

- Rotogravure: This technique uses engraved cylinders to transfer ink to a substrate.

- Lithography: This technique uses a flat printing plate to transfer ink to a substrate.

- Digital printing: This technique uses a computer-controlled printer to transfer ink to a substrate.

The type of printing technique used will depend on the specific product being produced.

2. Practice Your Answers to Common Interview Questions

Some common interview questions that you may be asked include:

- Tell me about your experience with plastic printing.

- What are your strengths and weaknesses as a plastic printer?

- Why are you interested in working for our company?

- What are your salary expectations?

3. Be Prepared to Talk About Your Skills and Experience

In addition to your technical skills, you should also be able to talk about your soft skills, such as your communication, teamwork, and problem-solving skills.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plastic Printer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.