Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plastic Shaper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

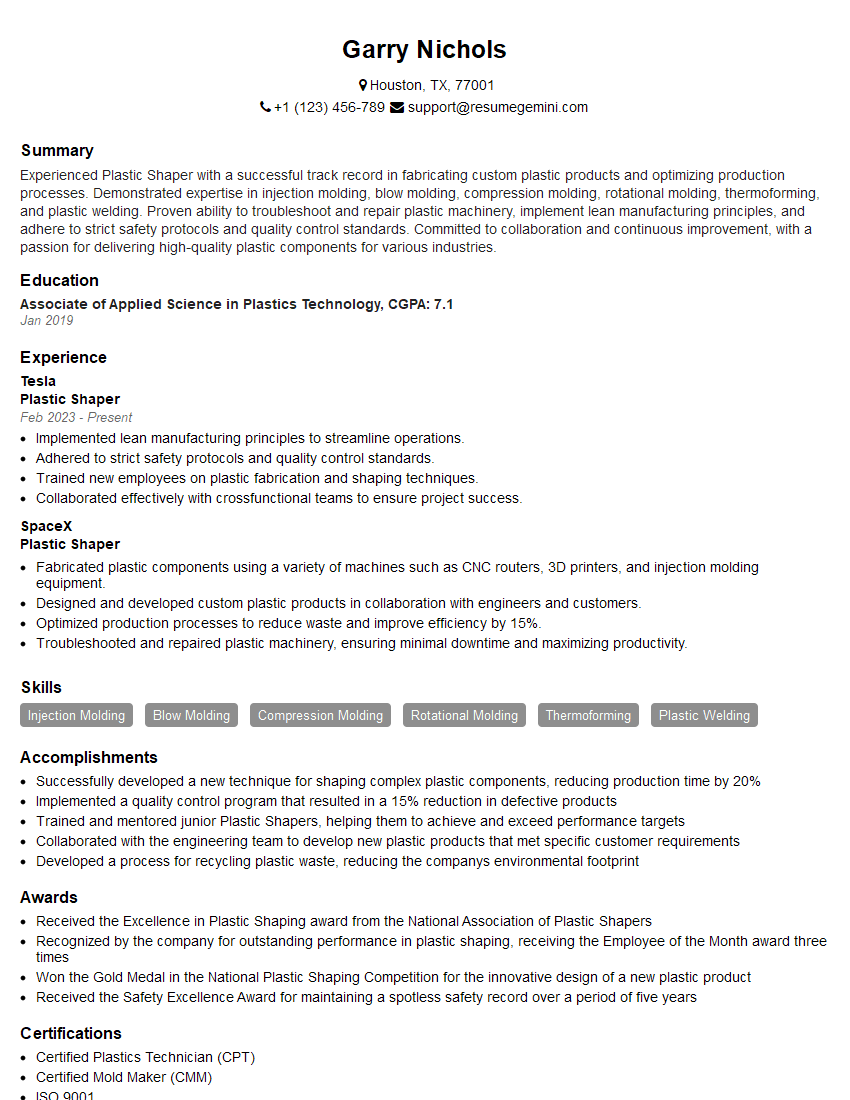

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Shaper

1. What are the different types of plastic shaping processes?

There are various plastic shaping processes, including:

- Injection molding: Molten plastic is injected into a mold under high pressure, forming the desired shape.

- Blow molding: A hollow plastic tube is inflated and shaped using compressed air.

- Extrusion: Molten plastic is forced through a die to create continuous profiles, such as pipes or sheets.

- Thermoforming: Plastic sheets are heated and stretched over a mold, conforming to its shape.

- Rotational molding: Plastic powder is placed in a mold that rotates and heats, creating hollow objects.

2. What factors influence the selection of a plastic shaping process?

Factors influencing process selection include:

Material Properties:

- Plastic type (e.g., polyethylene, polypropylene)

- Flowability

- Shrinkage rate

Product Design:

- Shape complexity

- Wall thickness

- Surface finish requirements

Production Volume:

- Small-batch or mass production

- Cycle time requirements

Cost:

- Mold costs

- Equipment costs

- Material costs

3. Describe the key steps involved in injection molding.

Injection molding steps include:

- Mold preparation: Cleaning and heating the mold.

- Material preparation: Drying and feeding plastic pellets into the machine.

- Injection: Molten plastic is injected into the mold using a reciprocating screw.

- Cooling: The mold is cooled to solidify the plastic.

- Ejection: The finished product is ejected from the mold.

4. What are the common defects associated with plastic shaping processes?

Potential defects include:

- Warpage: Distortion of the plastic part due to uneven cooling.

- Shrinkage: Change in dimensions during cooling and solidification.

- Flash: Excess material squeezing out of the mold.

- Voids: Air pockets or gaps within the plastic.

- Weld lines: Visible lines where plastic flows meet in the mold.

5. How do you ensure the quality of plastic shaped products?

Quality assurance measures include:

- Mold design: Optimizing mold design to minimize defects.

- Material selection: Choosing the appropriate plastic resin.

- Process control: Monitoring and controlling molding parameters (e.g., temperature, pressure).

- Inspection: Visual and dimensional inspection of finished products.

- Statistical Process Control (SPC): Tracking and analyzing data to identify and reduce defects.

6. How do you handle scrap or rejected plastic parts?

Scrap management involves:

- Recycling: Reusing scrap for future production.

- Landfilling: Disposing of non-recyclable scrap in a safe and environmentally responsible manner.

- Waste minimization: Implementing practices to reduce scrap production.

7. What are the latest trends in plastic shaping technology?

Emerging trends include:

- Multi-material molding: Combining different plastics or composites in a single process.

- Additive manufacturing (3D printing): Creating plastic parts layer by layer.

- Sustainable materials: Using environmentally friendly plastics.

- Automation: Reducing manual labor and increasing efficiency.

- Real-time monitoring: Tracking and controlling molding parameters in real-time.

8. How do you stay updated on industry best practices and advancements?

I stay abreast of developments in the plastic shaping industry through:

- Conferences and trade shows: Attending industry events to learn about new technologies and connect with experts.

- Industry publications and journals: Subscribing to specialized magazines and research papers.

- Online resources: Utilizing online platforms, forums, and websites for information and knowledge sharing.

- Networking: Building relationships with professionals in the field to exchange ideas and learn from their experiences.

9. How do you manage a team of plastic shapers?

Team management involves:

Leadership and Motivation:

- Setting clear goals and expectations.

- Providing guidance and support to team members.

- Recognizing and rewarding achievements.

Communication and Collaboration:

- Establishing open lines of communication.

- Facilitating team meetings and discussions.

- Promoting teamwork and collaboration.

Training and Development:

- Providing training on new technologies and processes.

- Encouraging continuous learning and professional growth.

- Identifying and nurturing future leaders.

Performance Management:

- Setting performance goals and providing regular feedback.

- Conducting performance evaluations and developing improvement plans.

- Ensuring accountability and addressing underperformance.

10. What is your experience in troubleshooting and solving production issues?

I have a proven track record in troubleshooting and resolving production issues by:

- Problem identification: Analyzing symptoms and collecting data to identify the root cause.

- Solution generation: Brainstorming and evaluating potential solutions.

- Implementation: Implementing solutions and monitoring their effectiveness.

- Continuous improvement: Evaluating the results and making adjustments to optimize performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Shaper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Shaper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Shapers are professionals who are responsible for manipulating and shaping plastic materials into desired forms.

1. Plastic Molding

Mold plastic materials into desired parts and shapes using a variety of techniques, such as extrusion molding and blow molding.

- Operate and calibrate the plastic molding equipment.

- Monitor the molding process and make adjustments as necessary to ensure quality.

2. Plastic Shaping

Shape and form plastic materials using hand tools and machines, such as saws, drills, and sanders.

- Trim, cut, and shape plastic parts to meet specifications.

- Inspect finished plastic products for defects and quality.

3. Plastic Fabrication

Fabricate and assemble plastic parts and components into finished products.

- Weld, glue, or otherwise fasten plastic parts together.

- Assemble plastic products according to design specifications.

4. Plastic Repair

Inspect and repair damaged plastic products, such as toys, appliances, and automotive parts.

- Diagnose and assess plastic damage.

- Repair plastic products using appropriate techniques, such as welding and bonding.

Interview Tips

Preparing for a Plastic Shaper interview requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and culture. Learn about the specific responsibilities and requirements of the Plastic Shaper role.

- Visit the company’s website to gather information.

- Read online reviews and articles about the company and industry.

2. Highlight Your Technical Skills

Emphasize your proficiency in plastic molding, shaping, fabrication, and repair techniques. Provide specific examples of your experience using these skills.

- Quantify your accomplishments by providing metrics and results.

- Use keywords from the job description in your responses.

3. Showcase Your Problem-Solving Abilities

Plastic Shapers often encounter challenges in shaping and repairing plastic materials. Describe situations where you successfully solved problems and developed innovative solutions.

- Follow the STAR method (Situation, Task, Action, Result) when answering behavioral questions.

- Be prepared to discuss specific examples of how you overcame technical difficulties.

4. Demonstrate Your Attention to Detail

Plastic Shaping requires precision and accuracy. Emphasize your meticulousness and attention to detail in your work. Provide examples of how you ensure quality and consistency.

- Describe your quality control procedures and inspection methods.

- Discuss your experience in meeting tight tolerances and customer specifications.

5. Practice Your Communication Skills

Communication is crucial for Plastic Shapers to collaborate with other team members and customers. Practice articulating your ideas clearly and concisely.

- Prepare answers to common interview questions about your communication style.

- Use active listening skills to show that you are attentive and understand the interviewer’s questions.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Plastic Shaper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.