Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plastic Sheets Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plastic Sheets Supervisor so you can tailor your answers to impress potential employers.

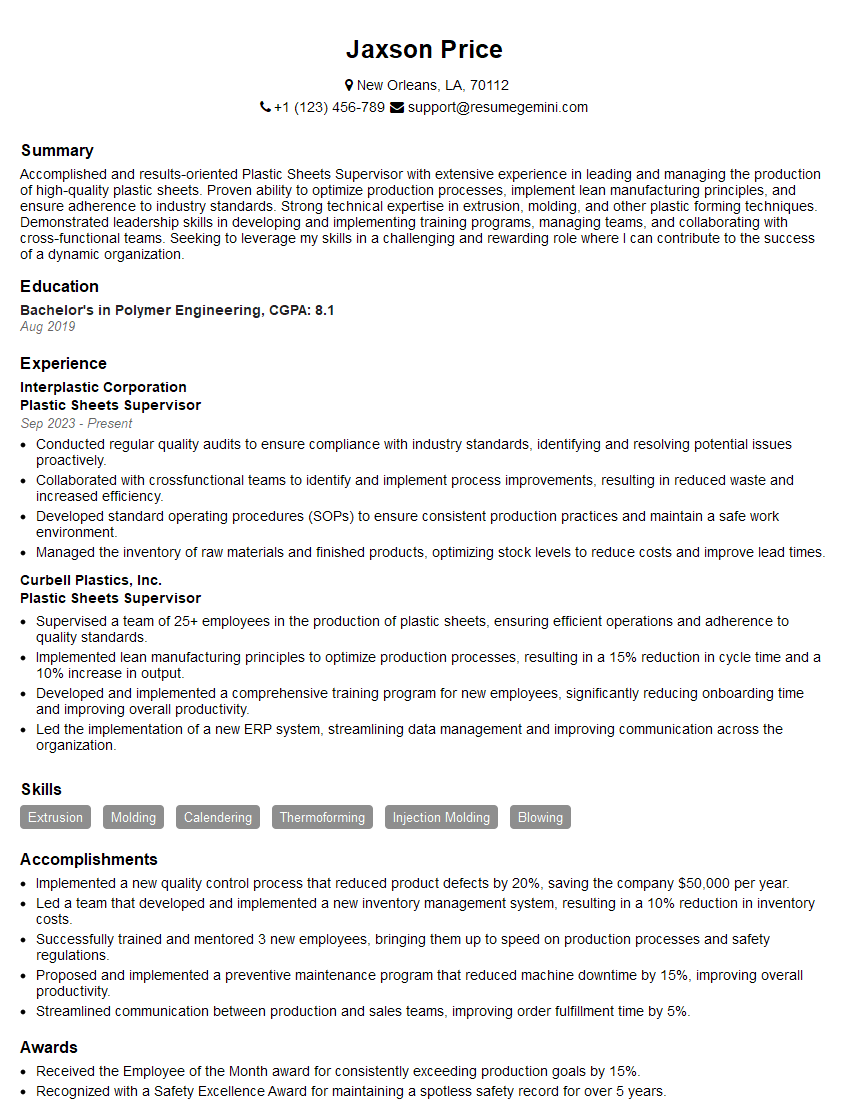

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Sheets Supervisor

1. How would you ensure the quality of plastic sheets produced in your department?

- Implement and monitor quality control standards throughout the production process.

- Conduct regular inspections of raw materials, equipment, and finished products.

- Train and supervise operators on quality control procedures.

- Analyze quality data to identify areas for improvement.

- Work with suppliers and customers to establish quality specifications.

2. What are the key factors that affect the efficiency of plastic sheet extrusion?

Extruder Performance

- Screw design and configuration

- Temperature control

- Pressure control

Material Properties

- Viscosity

- Melting point

- Additives

Process Parameters

- Extrusion rate

- Die gap

- Cooling rate

3. How would you troubleshoot a problem with the thickness uniformity of plastic sheets?

- Inspect the die for any damage or wear.

- Check the extruder settings and adjust as necessary.

- Inspect the cooling system for any blockages or leaks.

- Review the material properties and adjust the process parameters accordingly.

- Perform a thorough inspection of the equipment to identify any other potential issues.

4. What are the different types of plastic sheet extrusion processes?

- Flat Die Extrusion: Produces sheets with uniform thickness and smooth surfaces.

- Blown Film Extrusion: Produces thin, flexible sheets with a tubular shape.

- Cast Film Extrusion: Produces sheets with high optical clarity and low haze.

- Coextrusion: Produces sheets with multiple layers of different materials.

5. What are the safety precautions that must be taken when working with plastic sheet extrusion equipment?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Follow all safety procedures and protocols.

- Be aware of the hazards associated with the equipment, such as heat, sharp edges, and moving parts.

- Keep the work area clean and organized.

- Report any accidents or incidents immediately.

6. What are the key performance indicators (KPIs) for a plastic sheets production department?

- Production volume

- Quality yield

- Material utilization

- Production efficiency

- Customer satisfaction

7. How would you manage a team of plastic sheet extrusion operators?

- Provide clear instructions and expectations.

- Train and develop operators on technical skills and safety protocols.

- Monitor operator performance and provide feedback.

- Empower operators to solve problems and make decisions.

- Foster a positive and supportive work environment.

8. What are the latest trends in plastic sheet extrusion technology?

- Increased use of automation and robotics.

- Adoption of advanced materials with enhanced properties.

- Development of new extrusion processes for improved efficiency and quality.

- Focus on sustainable and environmentally friendly technologies.

9. How do you stay up-to-date with the latest advancements in plastic sheet extrusion?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Network with other professionals in the field.

- Participate in online forums and webinars.

- Take continuing education courses.

10. Why are you interested in this position, and how do you believe your skills and experience align with the requirements?

- I am eager to contribute my expertise in plastic sheet extrusion to your organization.

- My strong technical skills and experience in quality control, process optimization, and team management make me a suitable candidate for this role.

- I am confident that I can lead your plastic sheets production department to achieve its goals and objectives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Sheets Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Sheets Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Sheets Supervisors are responsible for overseeing the production of plastic sheets, ensuring that they meet quality standards and are produced efficiently. Their key responsibilities include:

1. Production Management

Supervising and coordinating the production process of plastic sheets, including scheduling, resource allocation, and monitoring production progress.

- Developing and implementing production plans and schedules.

- Allocating resources, such as personnel, equipment, and materials.

- Monitoring production progress and identifying and resolving bottlenecks.

2. Quality Control

Ensuring that plastic sheets meet quality standards, including conducting inspections, testing, and implementing corrective actions.

- Establishing and maintaining quality control standards.

- Conducting regular inspections and testing of plastic sheets.

- Identifying and resolving quality issues.

3. Team Management

Leading and motivating a team of production workers, providing guidance, training, and feedback.

- Providing leadership and direction to the production team.

- Training and developing team members.

- Providing feedback and coaching to improve performance.

4. Safety Management

Ensuring the safety of employees and the workplace, including implementing and enforcing safety protocols.

- Developing and implementing safety protocols and procedures.

- Conducting safety training for employees.

- Monitoring and enforcing safety regulations.

Interview Tips

1. Research the Company and Position

Familiarize yourself with the company’s website, annual reports, and industry news. Research the specific role and its responsibilities. This will help you tailor your answers to the interviewer’s questions and demonstrate your interest in the position.

2. Practice Answering Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this role,” and “What are your strengths and weaknesses?” Practice your answers to convey your skills, experience, and qualifications effectively.

Tell me about yourself. Introduce yourself with your name and educational background. Briefly describe your work experience, highlighting skills and accomplishments relevant to the role. State your career goals and how they align with the company’s values and the position’s requirements.

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job requirements. Quantify your accomplishments using specific metrics and examples. For instance, instead of saying “I managed a team,” you could say “I led a team of 10 production workers, resulting in a 20% increase in productivity.”

4. Demonstrate Your Enthusiasm and Fit

Throughout the interview, show your enthusiasm for the role and the company. Explain why you are a good fit for the position and how your skills and experience can contribute to the team’s success. Be prepared to share examples of your past accomplishments that demonstrate your abilities.

5. Ask Meaningful Questions

At the end of the interview, ask thoughtful questions to show your interest and engagement. Inquire about the company’s culture, growth opportunities, or industry trends. This also gives you an opportunity to clarify any information or ask for further details.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plastic Sheets Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!