Feeling lost in a sea of interview questions? Landed that dream interview for Plastic Tool Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plastic Tool Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

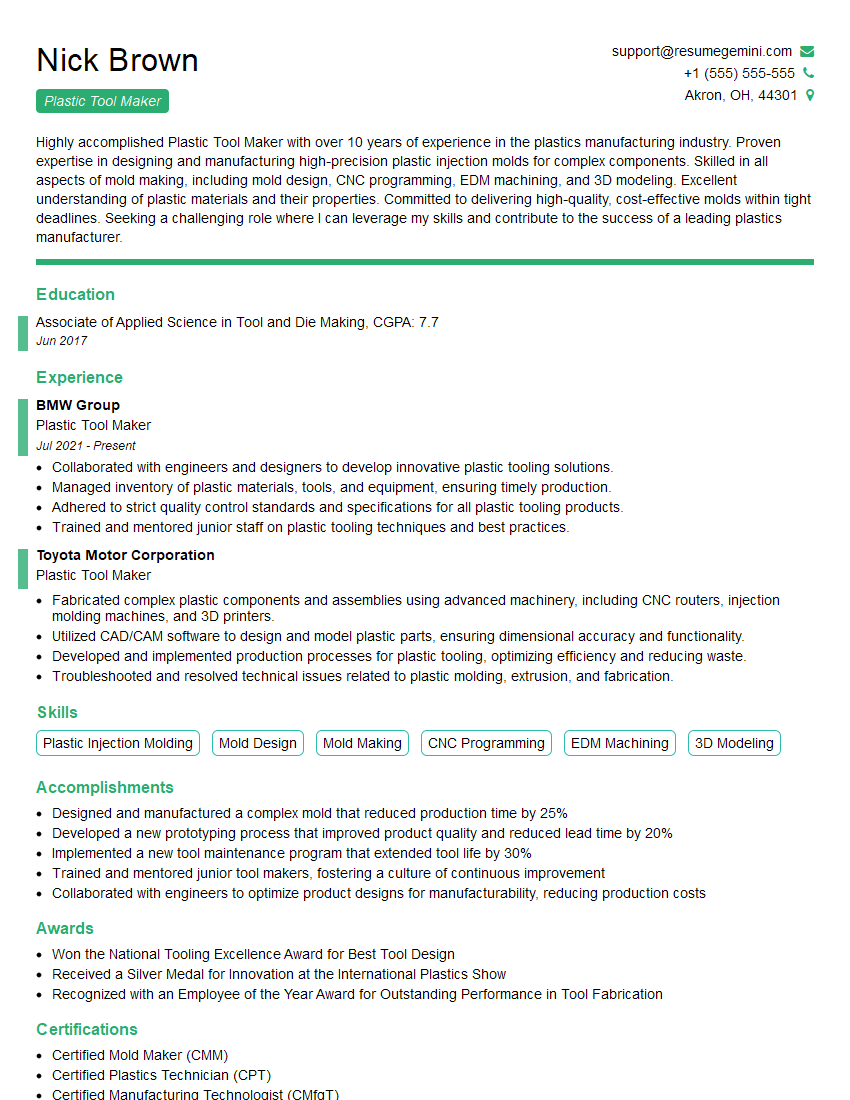

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Tool Maker

1. Explain the process of designing and creating a plastic mold?

- I start by understanding the product requirements and specifications.

- I then create a 3D model of the product using CAD software.

- Once the 3D model is complete, I create a mold design using CAM software.

- The mold design is then used to create the mold using CNC machining or other manufacturing processes.

- Finally, I test the mold to ensure that it produces high-quality parts.

2. What are the different types of plastic molding processes?

Injection molding

- Injection molding is a high-pressure process that forces molten plastic into a mold.

- Injection molding is used to produce a wide variety of plastic products, including toys, appliances, and automotive parts.

Blow molding

- Blow molding is a process that uses air pressure to inflate a molten plastic parison into a mold.

- Blow molding is used to produce hollow plastic products, such as bottles, containers, and toys.

Rotational molding

- Rotational molding is a process that heats and rotates a mold containing molten plastic.

- Rotational molding is used to produce large, hollow plastic products, such as storage tanks, kayaks, and playground equipment.

3. What are the key factors to consider when selecting a plastic material for a mold?

- The product’s intended use

- The product’s required properties, such as strength, flexibility, and durability

- The cost of the plastic material

- The availability of the plastic material

4. What are the common problems that can occur during plastic molding?

- Short shots

- Flash

- Sink marks

- Warping

- Bubbles

5. How do you troubleshoot and resolve common plastic molding problems?

- I first identify the cause of the problem.

- I then implement a solution to fix the problem.

- I finally test the solution to ensure that the problem has been resolved.

6. What are the latest trends in plastic molding technology?

- The use of advanced materials, such as bioplastics and nanomaterials

- The development of new molding processes, such as additive manufacturing and micro molding

- The use of automation and robotics to improve efficiency and productivity

7. What is your experience with using CAD/CAM software for mold design and manufacturing?

- I have extensive experience using CAD/CAM software for mold design and manufacturing.

- I am proficient in using a variety of CAD/CAM software packages, including SolidWorks, AutoCAD, and Mastercam.

- I have used CAD/CAM software to design and manufacture a wide variety of molds, including molds for injection molding, blow molding, and rotational molding.

8. What are your strengths as a plastic mold maker?

- I am a highly skilled and experienced plastic mold maker.

- I have a strong understanding of the plastic molding process.

- I am proficient in using CAD/CAM software for mold design and manufacturing.

- I am a team player and I am always willing to go the extra mile.

9. What are your weaknesses as a plastic mold maker?

- I sometimes have difficulty meeting deadlines.

- I can be a bit of a perfectionist.

- I am not always good at delegating tasks.

10. Why are you interested in working as a plastic mold maker for our company?

- I am interested in working as a plastic mold maker for your company because I am impressed by your company’s commitment to quality and innovation.

- I believe that my skills and experience would be a valuable asset to your team.

- I am eager to learn more about your company and the plastic molding industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Tool Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Tool Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

- Prepare, repair, and modify plastic tooling, such as molds, dies, and jigs.

- Design and build new plastic tooling using CAD/CAM software.

- Troubleshoot and resolve tooling problems.

- Inspect and maintain tooling to ensure quality.

- Work closely with engineers and production staff to ensure that tooling meets specifications.

- Use a variety of hand and power tools, including lathes, mills, grinders, and saws.

- Follow safety procedures and maintain a clean and organized work area.

Interview Tips

1. Research the Company and the Position

Take time to learn about the company’s history, products, and culture. Research the specific position you’re applying for and find out what skills and experience are required.

2. Practice Your Answers

Think about the common interview questions you’re likely to be asked and prepare your answers in advance. Practice speaking clearly and concisely, and use specific examples to illustrate your skills and experience.

3. Dress Professionally

First impressions matter, so dress professionally for your interview. This means wearing clean, pressed clothes and shoes. Avoid wearing casual clothing or revealing outfits.

4. Be Polite and Respectful

Be polite and respectful to everyone you meet during the interview process, including the receptionist, interviewer, and other staff members. This shows that you’re a professional and that you value the opportunity to interview for the position.

5. Ask Questions

At the end of the interview, take the opportunity to ask the interviewer any questions you have about the position or the company. This shows that you’re engaged and interested in the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plastic Tool Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!