Feeling lost in a sea of interview questions? Landed that dream interview for Plasticator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plasticator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

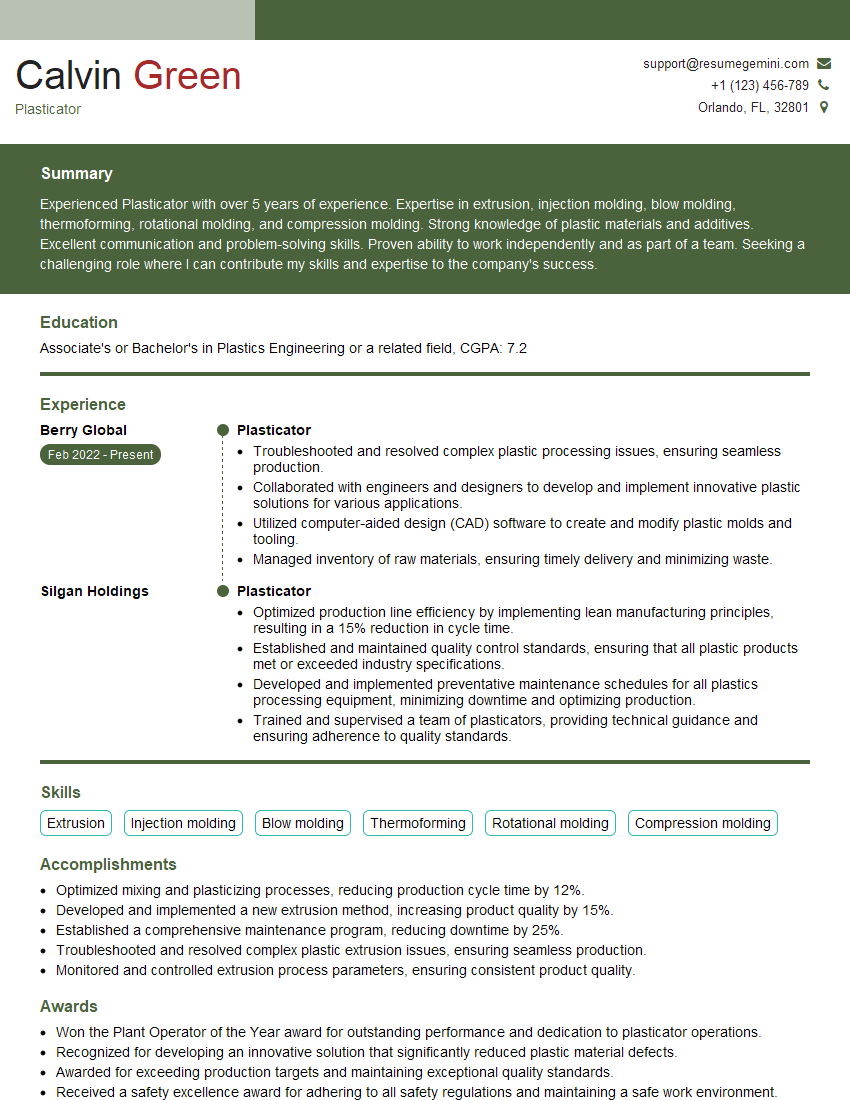

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plasticator

1. What is the difference between plastication and extrusion?

- Plasticization is the process of converting solid plastic into a molten state, while extrusion is the process of forcing the molten plastic through a die to create a desired shape.

- Plasticization occurs in the plasticator, while extrusion occurs in the extruder.

2. What are the different types of plasticators?

Screw plasticators

- Single-screw plasticators

- Twin-screw plasticators

Plunger plasticators

3. What are the factors that affect the efficiency of a plasticator?

- Plasticator type

- Screw speed

- Barrel temperature

- Polymer type

- Melt temperature

4. What are the common problems associated with plasticators?

- Screw wear

- Barrel wear

- Melt contamination

- Motor overheating

- Sealing problems

5. How do you troubleshoot a plasticator?

Here is a general outline of how to troubleshoot a plasticator:

- First, identify the problem.

- Next, determine the cause of the problem.

- Then, take steps to correct the problem.

- Finally, test the plasticator to ensure that the problem has been resolved.

6. What are the preventive maintenance tasks that can be performed on a plasticator?

- Regularly inspect the plasticator for wear and tear.

- Clean the plasticator regularly to remove any contaminants.

- Lubricate the moving parts of the plasticator.

- Check the electrical connections of the plasticator.

7. How do you operate a plasticator?

Here is a general outline of how to operate a plasticator:

- First, turn on the plasticator.

- Next, set the temperature of the plasticator.

- Then, add the plastic to the plasticator.

- Finally, run the plasticator until the plastic is melted.

8. What are the safety precautions that must be taken when operating a plasticator?

- Wear appropriate safety gear, including gloves, safety glasses, and a lab coat.

- Do not touch the hot surfaces of the plasticator.

- Keep the plasticator away from flammable materials.

- Do not operate the plasticator in a confined space.

9. What are the environmental regulations that apply to plasticators?

- The Clean Air Act

- The Clean Water Act

- The Resource Conservation and Recovery Act

10. What are the trends in the plasticator industry?

- The demand for plasticators is increasing.

- The development of new plasticators is increasing.

- The use of plasticators is becoming more regulated.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plasticator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plasticator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plasticators, as crucial members of manufacturing teams, play a pivotal role in the production of plastic products. Their responsibilities encompass a wide range of tasks, including:

1. Material Handling and Preparation

- Accurately weighing and mixing raw materials to achieve precise formulations

- Loading and unloading materials into and from hoppers, mixers, and extruders

2. Machine Operation and Monitoring

- Setting up, operating, and maintaining plasticators, extruders, and other equipment

- Monitoring machine performance, identifying and resolving any malfunctions or discrepancies

3. Quality Control and Inspection

- Conducting in-process and final inspections to ensure product quality meets specifications

- Identifying and correcting defects or flaws, maintaining high production standards

4. Process Optimization and Improvement

- Working with engineers and technicians to improve process efficiency and productivity

- Identifying areas for improvement, such as reducing waste or increasing output

Interview Tips

To ace an interview as a Plasticator, candidates should prepare thoroughly and consider the following tips:

1. Highlight Relevant Experience and Skills

- Emphasize previous experience in manufacturing environments, particularly in plastics production

- Showcase knowledge of plastics processing techniques, equipment, and quality control methods

2. Demonstrate Technical Proficiency

- Describe your understanding of plasticator operations, troubleshooting, and process improvement

- Be prepared to discuss specific techniques, such as color matching or material blending

3. Showcase Problem-Solving Abilities

- Provide examples of how you have identified and resolved production issues

- Discuss your approach to machine maintenance and error correction

4. Emphasize Attention to Detail

- Highlight your meticulous nature and ability to follow precise instructions

- Demonstrate your understanding of quality standards and your commitment to meeting them

5. Prepare for Common Interview Questions

- Practice answering questions about your experience, technical skills, and problem-solving abilities

- Research the company and the specific role you are interviewing for

Next Step:

Now that you’re armed with the knowledge of Plasticator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plasticator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini