Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plastics Fabrication Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

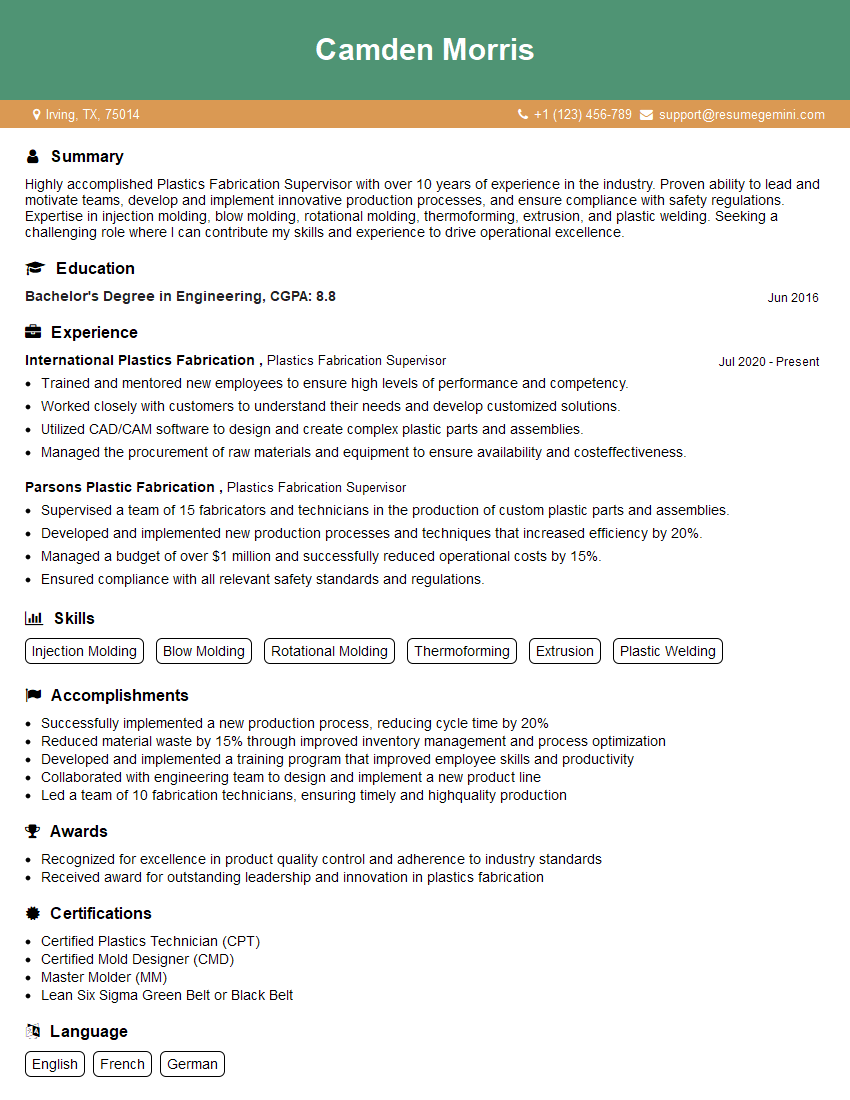

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastics Fabrication Supervisor

1. What are the different types of plastics that are used in fabrication?

- Thermoplastics: These plastics can be repeatedly softened by heat and re-solidified by cooling.

- Thermosets: These plastics undergo a chemical change when heated, resulting in a permanent change in shape.

2. What are the different methods of plastic fabrication?

of the answer: Thermoforming

- This process involves heating a plastic sheet until it becomes pliable and then shaping it using a mold.

Subheading of the answer: Injection Molding

- This process involves injecting molten plastic into a mold where it cools and solidifies.

3. What are the key factors to consider when selecting a plastic material for fabrication?

- The intended use of the product

- The required strength and durability

- The cost and availability of the material

4. What are the common defects that can occur during plastic fabrication?

- Voids

- Cracks

- Warping

5. What are the quality control measures that are used in plastic fabrication?

- Visual inspection

- Dimensional measurement

- Mechanical testing

6. What are the safety precautions that should be taken when working with plastics?

- Wearing appropriate protective gear

- Working in a well-ventilated area

- Following proper handling and storage procedures

7. Describe a typical day in the life of a Plastics Fabrication Supervisor.

- Monitor the production process and ensure that products meet quality standards.

- Train and supervise production staff.

- Troubleshoot and resolve production issues.

- Coordinate with other departments to ensure smooth operations.

8. What are the key challenges that you have faced in your previous role as a Plastics Fabrication Supervisor?

- Meeting production deadlines while maintaining quality standards.

- Motivating and leading a team of employees.

- Implementing new technologies and processes.

9. What are your strengths and weaknesses as a Plastics Fabrication Supervisor?

Strengths:

- Strong technical knowledge of plastics fabrication processes.

- Proven ability to lead and motivate a team.

- Excellent problem-solving skills.

Weaknesses:

- Limited experience with certain types of plastics.

- Working under pressure can sometimes lead to mistakes.

10. Why are you interested in this position, and why do you think you are the best candidate?

- I am interested in this position because it combines my technical skills with my passion for leadership.

- I have a proven track record of success as a Plastics Fabrication Supervisor, and I am confident that I can apply my skills and experience to drive success in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastics Fabrication Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastics Fabrication Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Plastics Fabrication Supervisor, you will be responsible for overseeing all aspects of the plastics fabrication process, from design and engineering to production and quality control. Your key responsibilities will include:

1. Planning and Scheduling

Develop production schedules and ensure that all projects are completed on time and within budget.

- Work with customers to determine their needs and develop project specifications.

- Estimate project costs and timelines.

2. Production Management

Manage all aspects of the production process, including:

- Scheduling and assigning work to fabrication technicians.

- Monitoring production progress and ensuring that all quality standards are met.

- Troubleshooting any production problems that may arise.

3. Quality Control

Ensure that all fabricated products meet or exceed customer specifications.

- Develop and implement quality control procedures.

- Inspect finished products and identify any defects.

- Work with fabrication technicians to correct any quality issues.

4. Safety Management

Ensure that all fabrication activities are conducted in a safe and environmentally responsible manner.

- Develop and implement safety procedures.

- Train fabrication technicians on safety protocols.

- Monitor the work environment and identify any potential safety hazards.

Interview Tips

Preparing for an interview for a Plastics Fabrication Supervisor position requires a combination of technical knowledge, industry experience, and effective communication skills. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Take the time to learn about the company’s history, products, and services. This will help you understand the company’s culture and values and how your skills and experience align with the position.

- Review the company’s website, social media pages, and recent press releases.

- Identify the specific requirements of the position and prepare examples of how your experience meets those requirements.

2. Highlight Your Technical Skills

As a Plastics Fabrication Supervisor, you need to have a strong understanding of plastics fabrication processes, materials, and equipment. Be prepared to discuss your knowledge of:

- Thermoforming, injection molding, and other fabrication techniques.

- Different types of plastics and their properties.

- Fabrication equipment and tooling.

3. Emphasize Your Leadership and Management Skills

Supervising a team of fabrication technicians requires strong leadership and management skills. Highlight your experience in the following areas:

- Motivating and leading a team of employees.

- Developing and implementing production schedules.

- Managing budgets and resources.

4. Show Your Commitment to Quality and Safety

Quality and safety are paramount in plastics fabrication. Emphasize your commitment to these values by discussing your experience in the following areas:

- Developing and implementing quality control procedures.

- Enforcing safety protocols and maintaining a safe work environment.

- Continuously improving processes to enhance quality and safety.

Next Step:

Now that you’re armed with the knowledge of Plastics Fabrication Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plastics Fabrication Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini