Are you gearing up for a career in Plastics Repairer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Plastics Repairer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

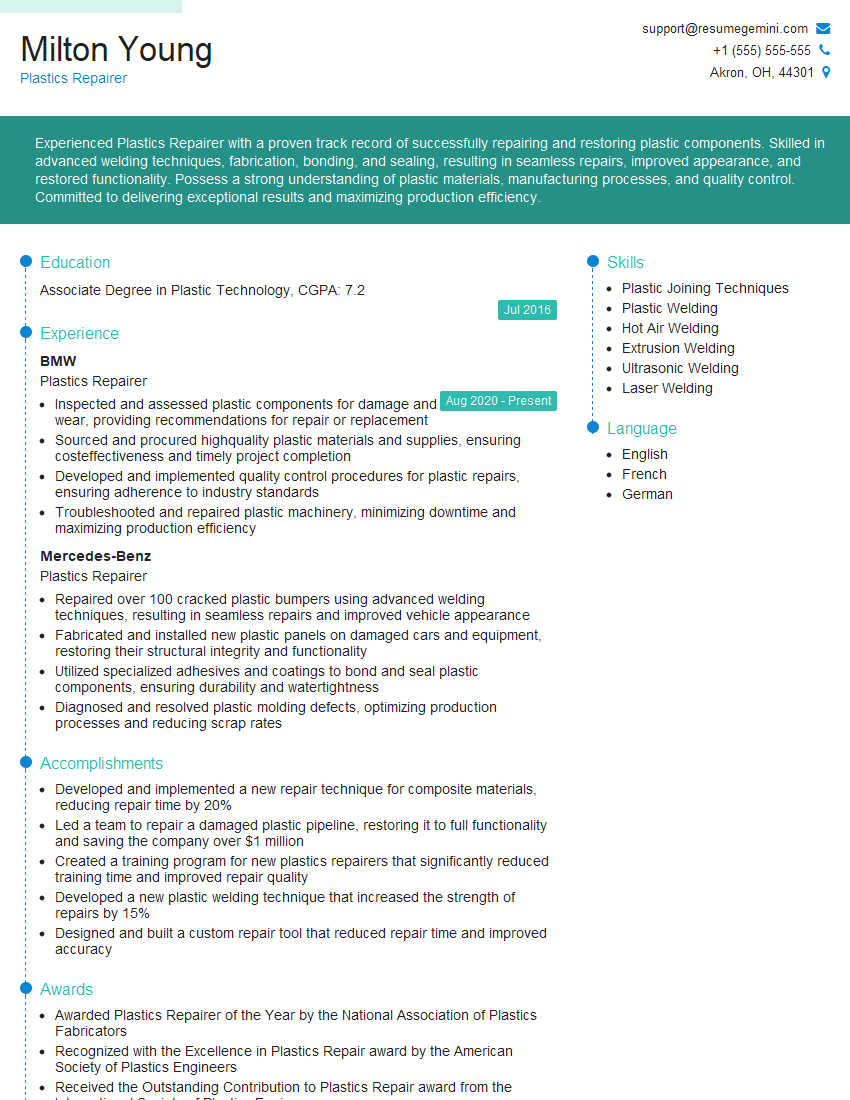

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastics Repairer

1. Which techniques do you use to determine the type of plastic for repair?

- Visual inspection of the material’s appearance, texture, and color

- Burn test to observe the flame characteristics and smell of the fumes

- Density test using a densitometer

- Solubility test using various solvents

- Infrared spectroscopy to analyze the molecular structure

2. Describe the steps involved in repairing a cracked plastic bumper.

Surface Preparation

- Clean and degrease the damaged area

- Sand the surface to create a rough texture for adhesion

Repair Process

- Apply a plastic welding rod of the same type as the bumper using a welding torch

- Smooth the weld seam using a grinding tool

- Fill any remaining gaps with a plastic filler

Finishing

- Sand and polish the repaired area to match the original surface

- Apply a primer and paint to restore the original appearance

3. How do you repair a damaged plastic dashboard?

The repair process varies depending on the type of damage and the location on the dashboard.

- For surface scratches, use a plastic polish or rubbing compound to remove the imperfections.

- For deeper scratches or gouges, fill the damaged area with a plastic filler, sand it smooth, and repaint or refinish the surface.

- For broken or cracked dashboards, the affected area may need to be replaced or repaired using plastic welding or adhesive bonding.

4. What types of plastic welding techniques are commonly used in plastic repair?

- Hot air welding: Uses a hot air gun to melt the plastic surfaces and fuse them together.

- Ultrasonic welding: Utilizes high-frequency vibrations to create friction and heat, melting and bonding the plastic surfaces.

- Infrared welding: Uses infrared radiation to heat and melt the plastic surfaces for bonding.

- Laser welding: Employs a laser to melt and fuse the plastic surfaces with precision.

5. How do you determine the correct type of adhesive to use for a specific plastic repair?

- Identify the type of plastic being repaired using the methods mentioned in Question 1.

- Consult manufacturer recommendations or technical data sheets for compatible adhesives.

- Consider the strength, flexibility, and temperature resistance required for the repair.

- Test a small area before applying the adhesive to the entire repair area.

6. What are the safety precautions that should be followed when working with plastics?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator if necessary.

- Provide adequate ventilation in the work area to prevent inhalation of fumes.

- Use caution when handling tools and equipment, especially when working with heat or sharp objects.

- Follow the manufacturer’s instructions for handling and storing plastic materials and adhesives.

- Dispose of waste and used materials properly according to environmental regulations.

7. How do you stay up-to-date with the latest techniques and advancements in plastic repair?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Participate in online forums and discussion groups.

- Seek training from manufacturers or distributors of plastic repair materials.

- Collaborate with other professionals in the field to exchange knowledge and experiences.

8. Describe your experience in repairing plastic components in the automotive industry.

Emphasize your skills in identifying plastic types, selecting appropriate repair techniques, and achieving high-quality results.

- Examples of projects, such as bumper repairs, dashboard repairs, and interior trim repairs.

- Techniques used, including welding, bonding, and refinishing.

- The outcomes achieved, including restored appearance, functionality, and durability.

9. How do you handle a situation where you encounter a new or unfamiliar type of plastic during a repair?

- Begin by thoroughly examining the material to determine its physical and visual characteristics.

- Research the material’s properties using online resources or manufacturer data.

- Consult with colleagues or industry experts for their insights and recommendations.

- Conduct small-scale tests on a non-critical area to determine the best repair approach.

- Once a suitable solution is identified, proceed with the repair process carefully.

10. How do you maintain a clean and organized workspace for plastic repair?

- Establish designated areas for different activities, such as cleaning, repair, and finishing.

- Use tool organizers to keep tools and equipment in their proper places.

- Regularly clean and disinfect work surfaces, tools, and equipment.

- Dispose of waste materials promptly and properly.

- Ensure adequate lighting and ventilation to maintain a comfortable and efficient workspace.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastics Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastics Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastics Repairers restore damaged plastic parts and products, utilizing various repair techniques and materials. They diagnose the damage, choose the right materials, and apply the appropriate repair technique to restore the plastic item to its original condition or improve its performance.

1. Damage Assessment and Repair Planning

A Plastics Repairer’s role begins with meticulously examining the damaged plastic component to determine the extent and nature of the damage. They analyze factors like the type of plastic, the cause of damage, and the required repair approach.

- Evaluate the damage, identify the type of plastic, and determine the cause of damage.

- Develop a repair plan, outlining the necessary materials, techniques, and steps.

2. Material Selection and Preparation

Choosing the appropriate materials is crucial for successful plastic repair. Plastics Repairers have a deep understanding of different plastic types and their properties, enabling them to select the right materials for each repair.

- Select compatible materials, adhesives, and fillers based on the type of plastic and damage.

- Prepare the materials according to the manufacturer’s instructions and safety protocols.

3. Surface Preparation and Repair Techniques

Proper surface preparation is essential for the success of plastic repairs. Plastics Repairers employ various surface preparation techniques, such as cleaning, sanding, and roughening, to ensure a strong bond between the repair material and the damaged surface.

- Clean and prepare the damaged area by removing dirt, grease, or contaminants.

- Apply repair techniques such as welding, gluing, or patching to restore the plastic’s integrity and strength.

4. Finishing and Quality Control

Once the repair is complete, Plastics Repairers perform finishing touches to restore the plastic item’s appearance and functionality. They inspect the repaired area to ensure it meets the required standards and specifications.

- Finish the repaired area by sanding, polishing, or texturing to match the original surface.

- Conduct quality control checks to ensure the repair meets the desired specifications and standards.

Interview Tips

Acing an interview for a Plastics Repairer position requires preparation and effective communication skills. Here are some valuable tips to help candidates succeed:

1. Research the Company and Position

Before the interview, candidates should thoroughly research the company and the specific Plastics Repairer position. Understanding the company’s industry, values, and products will help them tailor their responses and demonstrate their interest.

- Visit the company’s website, LinkedIn page, and Glassdoor reviews.

- Learn about the specific industry and the company’s role within it.

2. Highlight Relevant Skills and Experience

Candidates should emphasize their skills and experience that are relevant to the job description. This includes technical skills such as plastic repair techniques, material selection, and quality control, as well as soft skills like attention to detail and problem-solving.

- Quantify their accomplishments and provide specific examples of their work.

- Explain how their skills and experience align with the company’s needs.

3. Demonstrate Passion and Enthusiasm

Interviewers are looking for candidates who are passionate about plastics repair and eager to contribute to the company. Candidates should convey their enthusiasm for the field and their desire to learn and grow.

- Share their motivations for pursuing a career in plastics repair.

- Express their eagerness to learn new techniques and technologies.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that candidates are engaged and genuinely interested in the position. It is an opportunity to clarify any details and demonstrate their knowledge of the industry.

- Ask about the company’s current projects and future plans.

- Inquire about opportunities for professional development and training.

Next Step:

Now that you’re armed with the knowledge of Plastics Repairer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plastics Repairer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini