Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plastics Seasoner Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

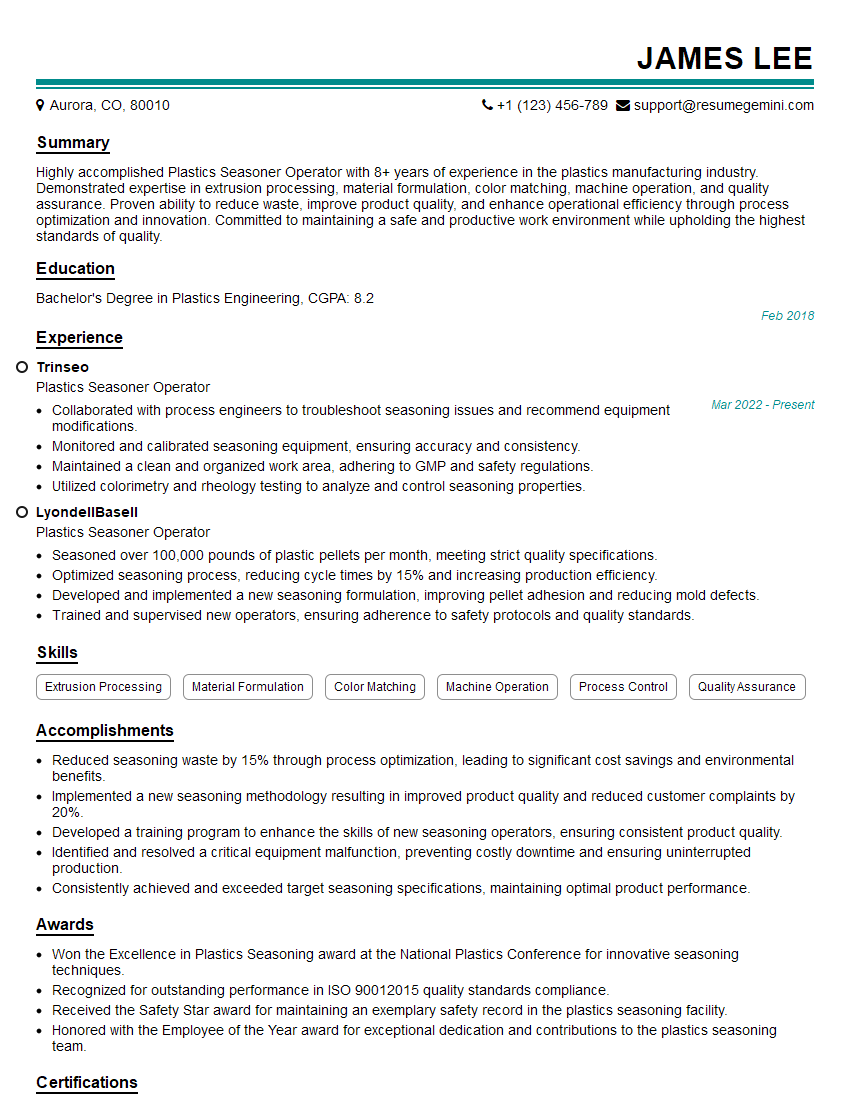

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastics Seasoner Operator

1. Explain the role of a Plastics Seasoner Operator?

The primary role of a Plastics Seasoner Operator is to operate and maintain equipment that seasons plastic products. Responsibilities include preparing and applying seasonings, ensuring color and weight accuracy, and maintaining machine efficiency. It involves handling chemicals, following technical specifications, and adhering to safety protocols.

2. Describe the process of seasoning plastics?

The seasoning process involves adding colorants, stabilizers, and other additives to plastic materials. We first mix the additives with the raw plastic pellets, ensuring uniform distribution. The mixture is then heated and processed using specialized equipment, such as a blender or extruder. Throughout the process, we monitor temperature, mixing time, and additive ratios to achieve the desired color and properties.

3. What are the types of equipment used in plastics seasoning?

- Blenders: Used to mix plastic pellets and additives evenly.

- Extruders: Machines that heat and melt the mixture, creating a uniform compound.

- Colorimeters and Spectrophotometers: Devices used to measure and control color consistency.

- Gravimetric Feeders: Systems that accurately weigh and dispense additives.

- Temperature Controllers: Regulate the heat applied during processing.

4. How do you ensure color accuracy during plastics seasoning?

Color accuracy is crucial. I use precise color measurement equipment, such as colorimeters or spectrophotometers, to quantify the color of the seasoned plastic. I compare the results to established standards and make adjustments to the additive ratios as needed. Regular calibration and maintenance of the equipment ensure reliable measurements.

5. What are the safety precautions to be taken while handling plastics seasoning chemicals?

- Wear appropriate protective gear, including gloves, mask, and eye protection.

- Follow the Material Safety Data Sheets (MSDS) for each chemical used.

- Handle chemicals in designated, well-ventilated areas.

- Dispose of chemicals properly according to environmental regulations.

- Report any spills or accidents immediately.

6. How do you monitor and control the consistency of the seasoning process?

Consistency is critical. I perform regular sampling and testing of the seasoned plastic. Tests include color measurement, weight analysis, and physical property evaluation. Based on the results, I make necessary adjustments to the seasoning process parameters, such as mixing ratios, temperature, and processing time, to maintain consistent quality.

7. What troubleshooting techniques do you apply when encountering problems in plastics seasoning?

When problems arise, I follow a systematic approach. I first identify the issue by observing symptoms, collecting data, and analyzing process parameters. Based on my understanding of the process, I develop hypotheses and test them by making adjustments to the seasoning conditions. I continue this iterative troubleshooting process until the issue is resolved.

8. How do you stay up-to-date with the latest advancements in plastics seasoning technology?

I actively seek opportunities to enhance my knowledge and skills. I attend industry conferences, read technical journals, and engage in online forums. I also participate in training programs offered by equipment manufacturers and industry experts. By staying informed, I can implement the latest advancements to improve efficiency and ensure the production of high-quality seasoned plastics.

9. Describe a challenging situation you faced as a Plastics Seasoner Operator and how you overcame it?

In a previous role, we encountered an issue where the color of the seasoned plastic was inconsistent. After thorough troubleshooting, I discovered that a faulty sensor in the gravimetric feeder was causing inaccurate additive dispensing. I promptly replaced the sensor, recalibrated the equipment, and monitored the process closely. The issue was resolved, resulting in consistent color and reduced production downtime.

10. Why are you interested in working as a Plastics Seasoner Operator in our company?

I am eager to join your company because I am impressed by your commitment to innovation and quality. I believe that my skills and experience in plastics seasoning, coupled with my dedication to continuous improvement, would be a valuable asset to your team. I am confident that I can contribute to your company’s success by ensuring the production of high-quality seasoned plastics that meet the highest standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastics Seasoner Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastics Seasoner Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastics Seasoner Operators are responsible for mixing and blending raw materials to create plastic products. They operate machinery to measure, weigh, and combine different types of plastic resins, additives, and colorants, ensuring that the correct proportions are used to meet product specifications. They also monitor the mixing process, making adjustments as necessary to maintain the desired properties of the plastic blend.

1. Raw Material Handling

Plastics Seasoner Operators are responsible for receiving and handling the raw materials used in the mixing process, which may include plastic resins, additives, and colorants. They check the quality of the materials and ensure that they meet the required specifications.

- Unload and inspect incoming raw materials

- Store raw materials in designated areas

- Retrieve raw materials as needed for production

2. Blending and Mixing

Plastics Seasoner Operators operate machinery to blend and mix the raw materials according to the desired specifications. They must carefully measure and weigh each component to ensure that the correct proportions are used.

- Measure and weigh raw materials

- Load raw materials into mixing equipment

- Operate blending and mixing equipment

- Monitor mixing process and make adjustments as needed

3. Quality Control

Plastics Seasoner Operators are responsible for ensuring that the finished plastic blend meets the required specifications. They conduct quality control tests and make adjustments to the mixing process as necessary.

- Conduct quality control tests on finished plastic blend

- Analyze test results and make adjustments to the mixing process as needed

- Maintain records of quality control tests

4. Equipment Maintenance

Plastics Seasoner Operators are responsible for maintaining the machinery used in the mixing process. They perform routine maintenance tasks and troubleshoot any problems that arise.

- Perform routine maintenance on mixing equipment

- Troubleshoot and repair equipment problems

- Maintain equipment logs and records

Interview Tips

To ace your interview for a Plastics Seasoner Operator position, it is important to prepare thoroughly and demonstrate your knowledge and skills. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Plastics Seasoner Operator position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website and social media pages

- Read industry news and articles

- Talk to people in your network who work in the plastics industry

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview. Think about your experiences and skills and how they relate to the job requirements.

- Use the STAR method to answer interview questions (Situation, Task, Action, Result)

- Practice answering questions about your experience with plastics, mixing, and quality control

- Prepare questions to ask the interviewer at the end of the interview

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for an office setting.

- Wear a suit or dress pants and a button-down shirt or blouse

- Choose conservative colors and avoid wearing anything too revealing

- Make sure your shoes are clean and polished

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Arrive at the interview on time or a few minutes early.

- Plan your route ahead of time and allow for extra time in case of traffic

- If you are running late, call or email the interviewer to let them know

5. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you and see if you are a good fit for the position. Be honest about your experiences and skills, and don’t try to be someone you’re not.

- Be confident and enthusiastic

- Be honest and forthright

- Be yourself and let your personality shine through

Next Step:

Now that you’re armed with the knowledge of Plastics Seasoner Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plastics Seasoner Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini