Feeling lost in a sea of interview questions? Landed that dream interview for Plastics Spreading Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plastics Spreading Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

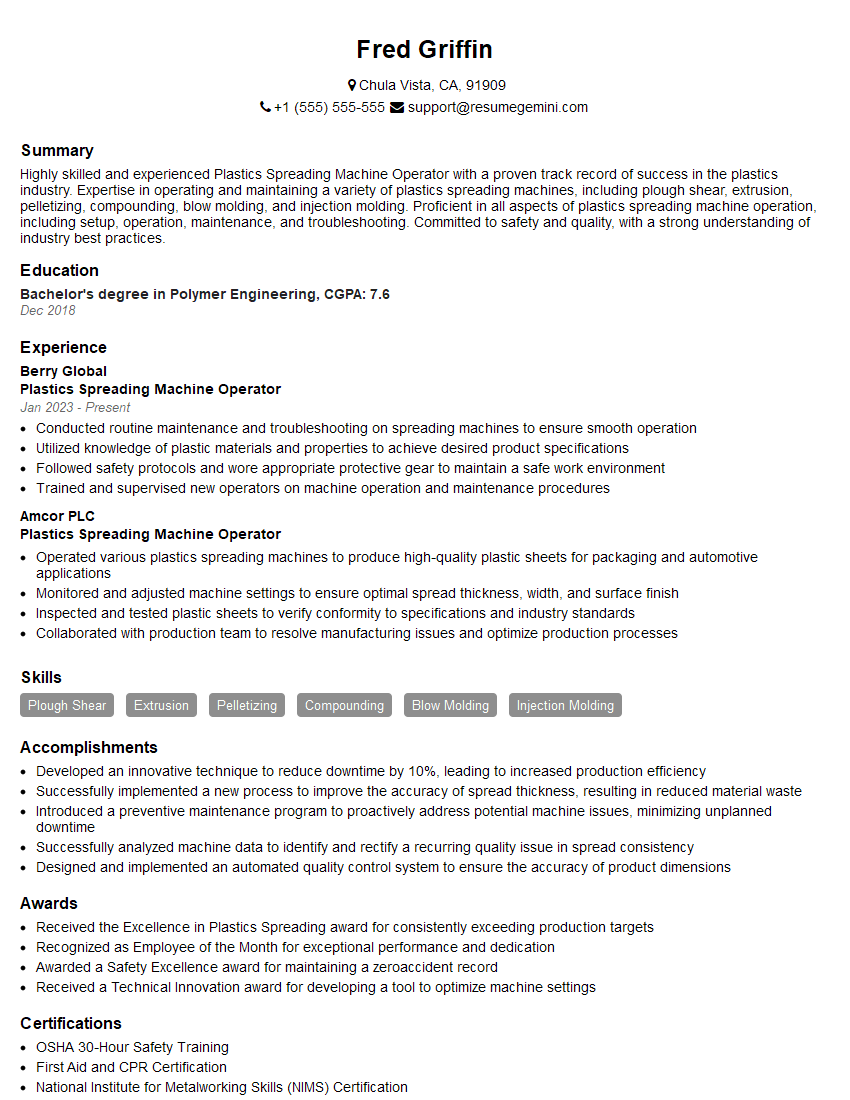

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastics Spreading Machine Operator

1. What are the key responsibilities of a Plastics Spreading Machine Operator?

The key responsibilities of a Plastics Spreading Machine Operator typically include:

- Operating and maintaining plastics spreading machines to produce plastic sheets or films

- Setting up and adjusting machine parameters to achieve desired product specifications

- Monitoring machine performance and making adjustments as needed

- Performing regular maintenance and troubleshooting to ensure machine efficiency

- Ensuring adherence to safety protocols and industry standards

2. Describe the different types of plastics spreading machines you have worked with.

There are various types of plastics spreading machines, each with its own characteristics:

Cast film extrusion machines

- Produce thin, flexible plastic films used in packaging, agriculture, and construction

- Utilize a rotating die to spread the molten plastic onto a cooling drum

Blown film extrusion machines

- Generate tubular plastic films used in packaging, automotive, and medical industries

- Employ a die to extrude the plastic into an upward-moving bubble, which is then cooled and flattened

Sheet extrusion machines

- Produce flat plastic sheets used in thermoforming, fabrication, and transportation

- Spread molten plastic through a die onto a cooling roller, resulting in a solid sheet

3. What are the critical parameters to monitor during plastics spreading operations?

Critical parameters to monitor during plastics spreading operations include:

- Extruder temperature and pressure

- Die gap and temperature

- Web tension and speed

- Cooling system performance

- Material properties and thickness

4. How do you troubleshoot common problems encountered during plastics spreading?

Common problems encountered during plastics spreading include:

- Web breaks: Check for incorrect temperature settings, improper material flow, or mechanical issues.

- Gauge variation: Adjust die gap or extruder speed, or check for material inconsistencies.

- Poor surface quality: Inspect die and cooling system for contamination or wear, and optimize temperature settings.

- Dimensional instability: Ensure proper cooling and annealing, and check for material shrinkage or expansion.

5. What safety precautions are essential when operating plastics spreading machines?

Essential safety precautions include:

- Wearing appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs

- Maintaining a clean and organized work area

- Following lockout/tagout procedures before performing maintenance

- Being aware of potential hazards such as heat, moving machinery, and electrical components

- Receiving regular safety training and updates

6. How do you ensure the quality of plastic sheets or films produced on the spreading machine?

To ensure quality, I follow these steps:

- Calibrating and maintaining the machine: Regularly check and adjust machine parameters to meet specifications.

- Monitoring critical parameters: Closely track temperature, pressure, web tension, and other factors to maintain optimal conditions.

- Performing quality checks: Regularly inspect products for defects, thickness variations, and surface imperfections.

- Adhering to quality standards: Comply with industry standards and company guidelines to ensure consistent quality.

- Seeking feedback: Consult with customers or quality control personnel to identify and address any quality concerns.

7. Describe your experience in optimizing the efficiency of plastics spreading operations.

To optimize efficiency, I have implemented the following measures:

- Process optimization: Analyzed production data and identified bottlenecks, implementing changes to improve machine utilization and reduce downtime.

- Preventive maintenance: Established a regular maintenance schedule to minimize breakdowns and ensure optimal performance.

- Training and development: Provided training to operators on best practices, troubleshooting techniques, and safety protocols to enhance productivity.

- Collaboration with other departments: Coordinated with engineers and quality control personnel to identify and resolve issues affecting efficiency.

8. How do you handle unexpected challenges or breakdowns during production?

In the event of unexpected challenges or breakdowns, I follow these steps:

- Stay calm and assess the situation: Identify the nature of the problem and its potential impact.

- Implement troubleshooting procedures: Utilize established protocols to diagnose and resolve the issue efficiently.

- Communicate with supervisors and team members: Keep relevant parties informed of the situation and coordinate efforts for a quick resolution.

- Document the incident and lessons learned: Record details of the breakdown and any corrective actions taken to prevent future occurrences.

9. What are your goals for this role as a Plastics Spreading Machine Operator?

My goals for this role include:

- Contribute to the company’s production targets by consistently operating the plastics spreading machine efficiently and safely.

- Enhance my skills and knowledge in plastics spreading operations, seeking opportunities for professional development.

- Collaborate effectively with team members and other departments to maintain a productive work environment.

- Identify areas for improvement and implement innovative solutions to optimize production processes.

- Contribute to the company’s success by adhering to quality standards and industry best practices.

10. Why should we choose you for this Plastics Spreading Machine Operator position?

You should consider me for this position because:

- I possess the technical skills and experience required to operate and maintain plastics spreading machines efficiently.

- I am committed to ensuring product quality and adhering to safety protocols.

- I am proactive in identifying and resolving issues, contributing to a productive work environment.

- I am eager to learn and grow professionally, seeking opportunities to enhance my knowledge and skills.

- I am a reliable and dedicated individual with a strong work ethic and a passion for the plastics industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastics Spreading Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastics Spreading Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastics Spreading Machine Operators are responsible for managing the operation and maintenance of plastics spreading machines in industrial settings. Their primary duties involve:

1. Machine Operation

Operate plastics spreading machines to apply a layer of plastic material onto a substrate, such as fabric or foam.

- Position and align materials on the machine bed.

- Adjust machine settings, including temperature, speed, and tension.

- Monitor the spreading process to ensure uniform coverage and quality.

2. Material Handling

Handle and load rolls of plastic material onto the machine.

- Unload finished products from the machine.

- Inspect incoming and outgoing materials for defects.

3. Maintenance and Repair

Perform routine maintenance on plastics spreading machines.

- Clean and lubricate machine components.

- Troubleshoot and repair minor malfunctions.

- Report major issues to supervisors.

4. Quality Control

Inspect finished products to ensure they meet quality standards.

- Identify and correct defects in the spreading process.

- Maintain records of quality control checks.

Interview Tips

To ace the interview for a Plastics Spreading Machine Operator position, consider the following tips:

1. Preparation

Before the interview, familiarize yourself with the job responsibilities and the company.

- Review the job description thoroughly.

- Research the company’s website and industry reputation.

- Practice answering common interview questions.

2. Technical Skills

During the interview, highlight your technical skills and knowledge of plastics spreading machines.

- Demonstrate your understanding of machine operation, maintenance, and troubleshooting.

- Provide examples of your experience in handling and inspecting materials.

- Explain how you ensure quality control in your work.

3. Soft Skills

Emphasize your soft skills, such as teamwork and communication.

- Explain how you collaborate with colleagues and supervisors.

- Provide examples of your ability to follow instructions and work independently.

- Show that you are reliable, organized, and detail-oriented.

4. Career Goals

Express your interest in the position and explain how it aligns with your career goals.

- Explain why you are passionate about working with plastics spreading machines.

- Share your plans for professional development and growth.

- Indicate your willingness to learn and take on new challenges.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plastics Spreading Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plastics Spreading Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.