Are you gearing up for a career in Plastics Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Plastics Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

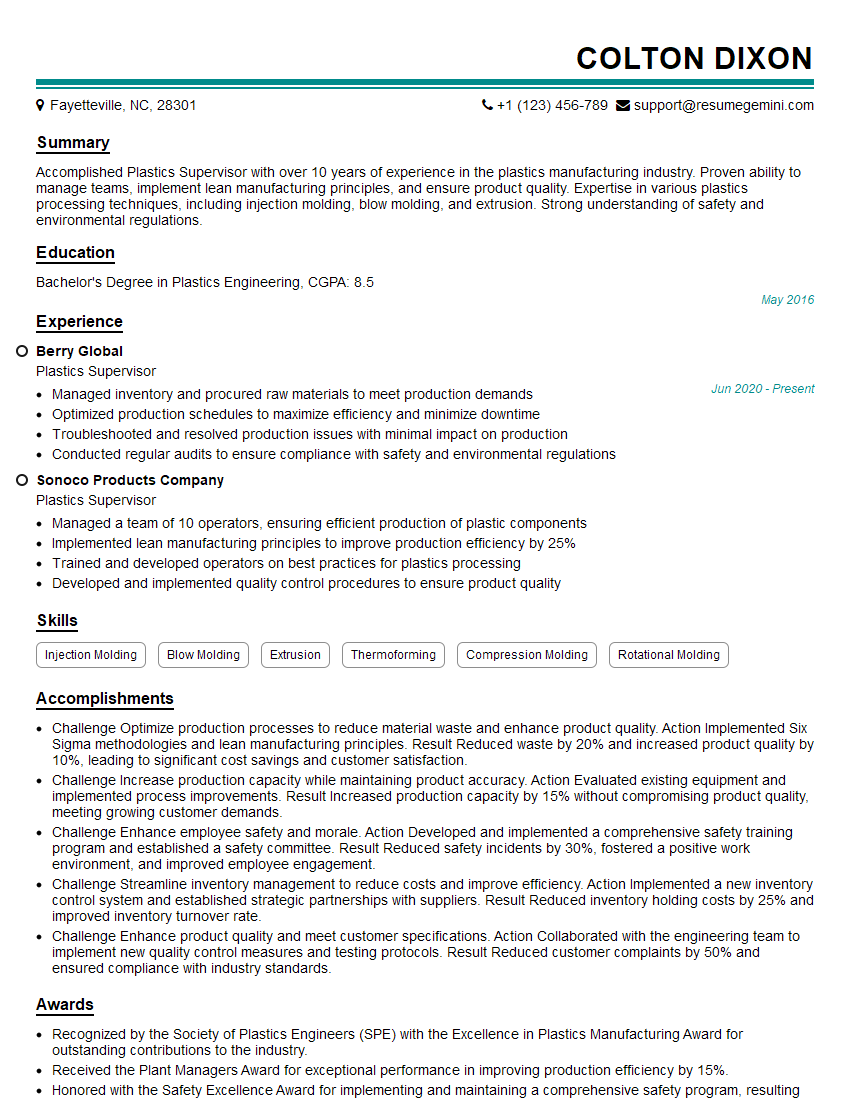

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastics Supervisor

1. Tell me about your experience in managing a team of plastics processing operators?

In my previous role as a Plastics Supervisor, I was responsible for leading a team of 10 operators in a plastics manufacturing plant. I ensured that the team met production targets, maintained quality standards, and followed safety protocols.

- Assigned tasks and monitored progress to ensure efficient operations.

- Provided training and support to team members to enhance their skills and productivity.

2. Explain the process of plastic injection molding and the critical parameters that need to be controlled?

Injection Molding Process

- Clamping the mold and injecting molten plastic into the mold cavity.

- Cooling and solidifying the plastic within the mold.

- Ejecting the molded part from the mold.

Critical Parameters

- Injection pressure and temperature

- Mold temperature and cooling time

- Clamping force

3. Describe the different types of plastics and their properties?

There are various types of plastics, each with unique properties:

- Polyethylene (PE): Flexible, low density, resistant to chemicals

- Polypropylene (PP): Strong, lightweight, high melting point

- Polyvinyl Chloride (PVC): Durable, versatile, resistant to fire and water

- Polyethylene Terephthalate (PET): Transparent, lightweight, used in packaging

- Polycarbonate (PC): Strong, transparent, heat-resistant

4. How do you ensure quality control in plastics manufacturing?

Quality control is crucial in plastics manufacturing:

- Visual Inspection: Examining parts for defects, such as cracks, scratches, or discoloration.

- Dimensional Measurement: Verifying part dimensions meet specifications.

- Physical Testing: Assessing properties like strength, flexibility, and impact resistance.

- Statistical Process Control (SPC): Monitoring and analyzing production data to identify and correct potential issues.

5. What are your strategies for improving production efficiency in a plastics manufacturing plant?

Strategies for improving production efficiency:

- Optimize Machine Utilization: Ensure machines are operating efficiently and minimize downtime.

- Streamline Production Processes: Identify and eliminate bottlenecks in the production line.

- Implement Automation: Leverage technology to automate repetitive tasks and increase productivity.

- Train Operators: Provide training to operators to enhance their skills and reduce errors.

6. How do you manage safety in a plastics manufacturing environment?

Safety is paramount in plastics manufacturing:

- Safety Protocols: Establish and enforce clear safety procedures for employees.

- Hazard Identification: Identify and assess potential hazards in the workplace.

- Personal Protective Equipment (PPE): Provide and ensure the use of appropriate PPE, such as gloves, goggles, and respirators.

- Training: Train employees on safety procedures and the proper handling of hazardous materials.

7. Tell me about your experience in using Six Sigma or other quality improvement methodologies?

In my role as a Plastics Supervisor, I applied Six Sigma methodologies to improve production processes and reduce defects.

- Define: Clearly defined the problem and its impact on production.

- Measure: Collected data to quantify the extent of the problem.

- Analyze: Identified the root causes of the problem.

- Improve: Implemented solutions to eliminate or mitigate the root causes.

- Control: Established measures to monitor and maintain the improvements.

8. How do you stay updated on the latest trends and technologies in plastics manufacturing?

I keep myself abreast of advancements in plastics manufacturing through various means:

- Industry Conferences: Attend industry events and conferences to learn about new technologies and best practices.

- Publications: Subscribe to trade magazines and journals to stay informed on industry trends.

- Online Resources: Utilize online platforms and research papers to stay current on advancements.

- Training and Workshops: Participate in training programs and workshops to enhance my knowledge and skills.

9. What are your strengths and weaknesses as a Plastics Supervisor?

Strengths

- Proven leadership skills and ability to manage a team effectively

- Strong technical understanding of plastics manufacturing processes

- Excellent problem-solving and decision-making abilities

- Commitment to quality and continuous improvement

Weaknesses

- Limited experience in certain specialized plastics manufacturing techniques

- Need to further develop proficiency in some software applications

10. How do you handle conflict resolution in the workplace?

Conflict resolution is an important aspect of workplace management:

- Listen Actively: Encourage open communication and actively listen to perspectives of all parties involved.

- Identify Root Causes: Explore the underlying causes of the conflict to address the core issues.

- Mediate and Facilitate: Guide discussions to find common ground and facilitate a mutually acceptable solution.

- Set Clear Expectations: Once a resolution is reached, establish clear expectations for moving forward.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastics Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastics Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plastics Supervisor leads, oversees, and mentors a team of professionals involved in the production of plastic products. They ensure the smooth functioning of the production process, maintain quality standards, and optimize productivity within the plastics manufacturing environment.

1. Production Management

Directs and coordinates all aspects of plastics production, including raw material procurement, production planning, and scheduling.

- Develops and implements production schedules to meet customer demand.

- Oversees the operation and maintenance of production equipment.

- Monitors production processes to ensure efficiency and quality.

- Identifies and resolves production issues promptly.

2. Quality Control

Establishes and maintains quality control standards for plastic products.

- Conducts regular inspections of raw materials, work-in-progress, and finished products.

- Ensures that products meet customer specifications and industry standards.

- Identifies and corrects quality defects.

- Develops and implements quality improvement programs.

3. Team Leadership

Leads, motivates, and develops a team of production operators.

- Provides training and guidance to team members.

- Creates a positive and productive work environment.

- Evaluates employee performance and provides feedback.

- Recognizes and rewards employee achievements.

4. Safety and Compliance

Ensures compliance with safety regulations and industry standards.

- Conducts safety inspections and training.

- Develops and implements emergency response plans.

- Monitors environmental compliance and waste management.

- Adheres to all applicable laws and regulations.

Interview Tips

Preparing thoroughly for a Plastics Supervisor interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Take the time to thoroughly research the company’s website, product line, and industry reputation. This will demonstrate your interest in the position and company and allow you to ask informed questions during the interview.

- Review the company’s mission statement, values, and recent news.

- Identify the key responsibilities and qualifications for the Plastics Supervisor role.

2. Quantify Your Accomplishments

When describing your previous experiences and accomplishments, be sure to use specific numbers and metrics to quantify your results. This will help the interviewer understand the tangible impact of your work.

- Example: Instead of saying “I improved production efficiency,” say “I implemented a new production process that resulted in a 15% increase in output.”

3. Highlight Your Technical Expertise

Plastics manufacturing is a highly technical field, so be prepared to discuss your knowledge of plastics materials, production processes, and quality control techniques. If you have any relevant certifications or training, be sure to mention them.

- Example: “I am certified in ISO 9001 quality management systems and have experience implementing Lean manufacturing principles.”

4. Emphasize Your Leadership Abilities

The ability to effectively lead and motivate a team is essential for a Plastics Supervisor. Highlight your experience in team management, conflict resolution, and employee development.

- Example: “In my previous role, I successfully led a team of 10 production operators, achieving a 98% on-time delivery rate.”

5. Practice Common Interview Questions

Take the time to practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare concise and well-thought-out responses that showcase your skills and experience.

- Example Outline:

- Introduction: Begin by briefly stating your name, position applying for, and years of experience.

- Body: Highlight your relevant skills and experience, providing specific examples and quantifying your results whenever possible. Emphasize your technical expertise, leadership abilities, and commitment to quality.

- Conclusion: Reiterate your interest in the position and how your skills and experience align with the company’s needs. Express your enthusiasm for contributing to the team’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plastics Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!