Feeling lost in a sea of interview questions? Landed that dream interview for Plate Corrector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plate Corrector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

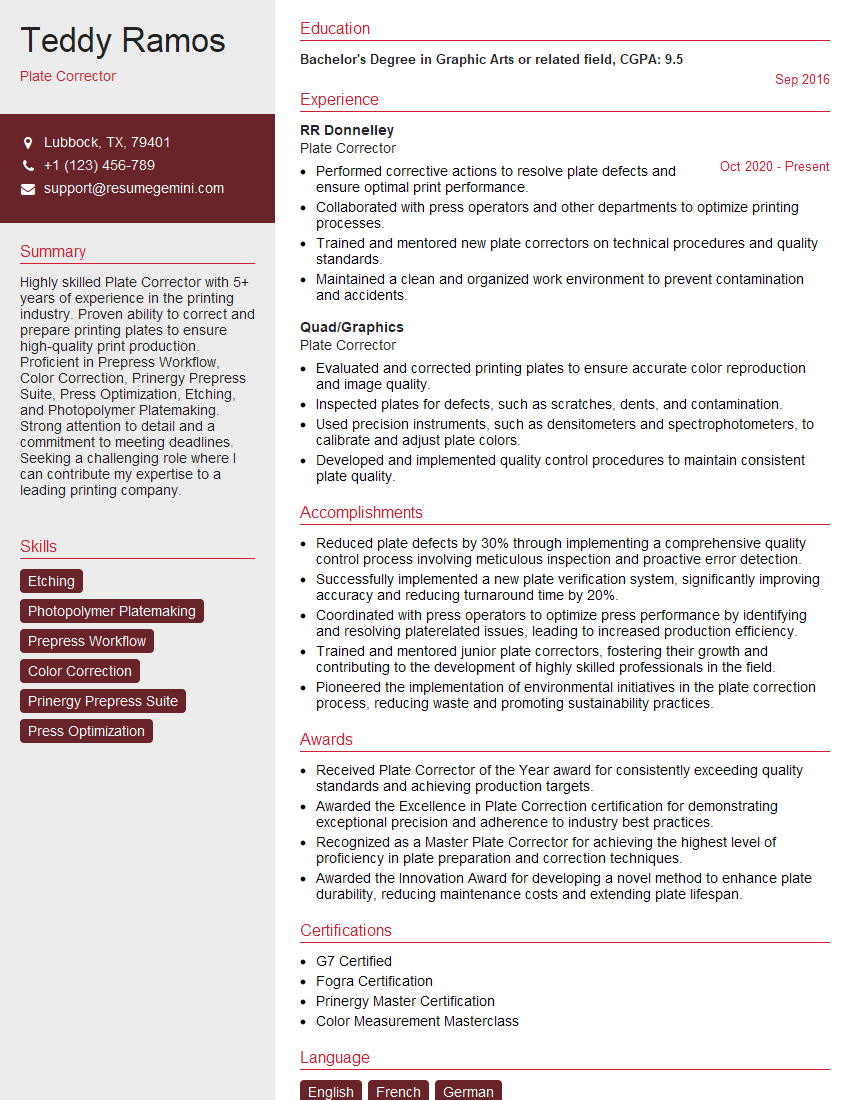

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plate Corrector

1. Describe the process of checking dimensions of a plate?

To check the dimensions of a plate, I would first measure its length, width, and height using a tape measure or micrometer. I would then compare the measurements to the specified dimensions on the engineering drawing or specification.

- If the plate falls within the specified tolerances, I would proceed with the next step.

- If the plate is outside of the specified tolerances, I would notify my supervisor and take corrective action.

2. How do you ensure that the surface of the plate is clean and free of contaminants?

Visual Inspection:

- Inspect the plate under a magnifying glass to look for any visible contaminants or defects.

- Use a flashlight to check for any areas that may be hidden from view.

Tactile Inspection:

- Wipe the plate with a clean cloth to feel for any raised or rough areas.

- Gently tap the plate with a hammer or other object to listen for any unusual sounds that may indicate a crack or other defect.

Chemical Inspection:

- Use a chemical cleaning solution to remove any contaminants from the surface of the plate.

- Rinse the plate with clean water and dry it with a clean cloth.

3. What is a crowning correction?

Crowning correction is a process used to correct the curvature of a plate. When a plate is bent or warped, it can create problems with flatness and parallelism. Crowning correction involves applying a controlled amount of force to the plate to bend it back into shape.

- Crowning correction can be done manually or with a machine.

- The amount of force required to correct the curvature will vary depending on the thickness and size of the plate.

4. What is the purpose of stress relieving a plate?

Stress relieving is a process used to remove residual stresses from a plate. Residual stresses can be caused by a variety of factors, such as welding, machining, or forming.

- Residual stresses can cause the plate to warp or crack.

- Stress relieving involves heating the plate to a high temperature and then slowly cooling it.

5. What are the different types of plate surfaces?

There are various types of plate surfaces, each with its own characteristics and applications:

- Hot-rolled: rough surface, used for applications where a smooth surface is not required.

- Cold-rolled: smooth surface, used for applications where a high degree of precision is required.

- Annealed: soft and ductile surface, used for applications where the plate needs to be bent or formed.

- Tempered: hard and wear-resistant surface, used for applications where the plate is subjected to high wear and tear.

- Galvanized: coated with zinc to resist corrosion, used for applications where the plate is exposed to moisture.

6. What are the most common defects found in plates?

- Scratches: caused by handling or machining.

- Dents: caused by impact or mishandling.

- Burrs: caused by shearing or cutting.

- Rust: caused by exposure to moisture.

- Corrosion: caused by exposure to chemicals or other corrosive agents.

7. How do you inspect a plate for defects?

- Visual inspection: look for scratches, dents, burrs, and other surface defects.

- Dimensional inspection: measure the plate to ensure it meets the specified dimensions.

- Ultrasonic inspection: use ultrasonic waves to detect internal defects.

- Magnetic particle inspection: use magnetic particles to detect surface defects.

- Dye penetrant inspection: use a dye to detect surface defects.

8. What are the different methods of cutting plates?

- Shearing: using a shear to cut the plate.

- Plasma cutting: using a plasma torch to cut the plate.

- Laser cutting: using a laser to cut the plate.

- Waterjet cutting: using a high-pressure waterjet to cut the plate.

9. What are the different methods of bending plates?

- Press brake: using a press brake to bend the plate.

- Roll bending: using a roll bender to bend the plate.

- Hand bending: using a hand brake or other manual method to bend the plate.

10. What are the different types of welding used to join plates?

- Arc welding: using an electric arc to join the plates.

- MIG welding: using a metal inert gas to join the plates.

- TIG welding: using a tungsten inert gas to join the plates.

- Spot welding: using a series of spot welds to join the plates.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plate Corrector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plate Corrector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plate Corrector is responsible for identifying and correcting errors on printing plates. The primary goal is to guarantee high-quality printing outputs by ensuring that the plates meet the required standards.

1. Plate Inspection and Correction

Meticulously inspects printing plates for defects, smudges, scratches, or any other imperfections using specialized equipment and visual examination.

- Identifies and marks areas that require touch-ups or corrections.

- Performs touch-ups and corrections using specialized tools and techniques, ensuring the restoration of the plate’s printing capabilities.

2. Quality Control

Maintains stringent quality standards by thoroughly inspecting plates before and after corrections.

- Utilizes precision measuring devices to verify plate dimensions, ensuring they meet specifications.

- Collaborates with press operators to identify potential printing issues and implement corrective measures.

3. Equipment Maintenance

Ensures the optimal performance of plate correction equipment by conducting regular maintenance checks.

- Cleans and calibrates equipment to maintain accuracy and efficiency.

- Performs minor repairs and troubleshooting to minimize equipment downtime.

4. Collaboration and Communication

Works closely with designers, press operators, and other team members to ensure effective communication and coordination.

- Provides feedback on plate quality and potential printing issues.

- Maintains accurate records of plate corrections and quality control measures.

Interview Tips

To ace the interview for a Plate Corrector position, it is crucial to demonstrate your technical proficiency, attention to detail, and problem-solving abilities. Here are some tips to help you prepare:

1. Research the Job and Company

Take the time to thoroughly research the job description and the company you are interviewing with. This will give you a clear understanding of the responsibilities, company culture, and industry trends.

- Check the company’s website, LinkedIn page, and industry news articles.

- Identify specific examples from your previous experience that align with the key job responsibilities.

2. Practice Your Technical Skills

As a Plate Corrector, your technical skills are paramount. Practice using specialized equipment and demonstrate your ability to identify and correct plate defects accurately.

- Review common plate inspection techniques and quality control procedures.

- Prepare examples of complex plate corrections you have performed.

3. Prepare for Common Interview Questions

Be prepared to answer common interview questions related to your experience, skills, and motivation for the role. Practice your responses to highlight your strengths and enthusiasm for the position.

- Example Question: “Describe a challenging plate correction you encountered and how you resolved it.”

- Example Question: “Why are you interested in a Plate Corrector role at our company?”

4. Emphasize Your Attention to Detail

Plate Correctors must possess an exceptional eye for detail to identify even minor imperfections on printing plates. In your interview, provide concrete examples of your ability to spot and address errors.

- Highlight your experience in using precision measuring devices and quality control techniques.

- Describe how you maintain accuracy and consistency in your work.

5. Show Your Problem-Solving Abilities

Plate Correctors often encounter unexpected challenges during plate inspections and corrections. Demonstrate your problem-solving skills and ability to think critically under pressure.

- Share examples of how you identified the root cause of plate defects and implemented effective solutions.

- Explain how you handle situations where multiple solutions are possible and justify your decision-making process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plate Corrector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!