Are you gearing up for a career in Plate Developer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Plate Developer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

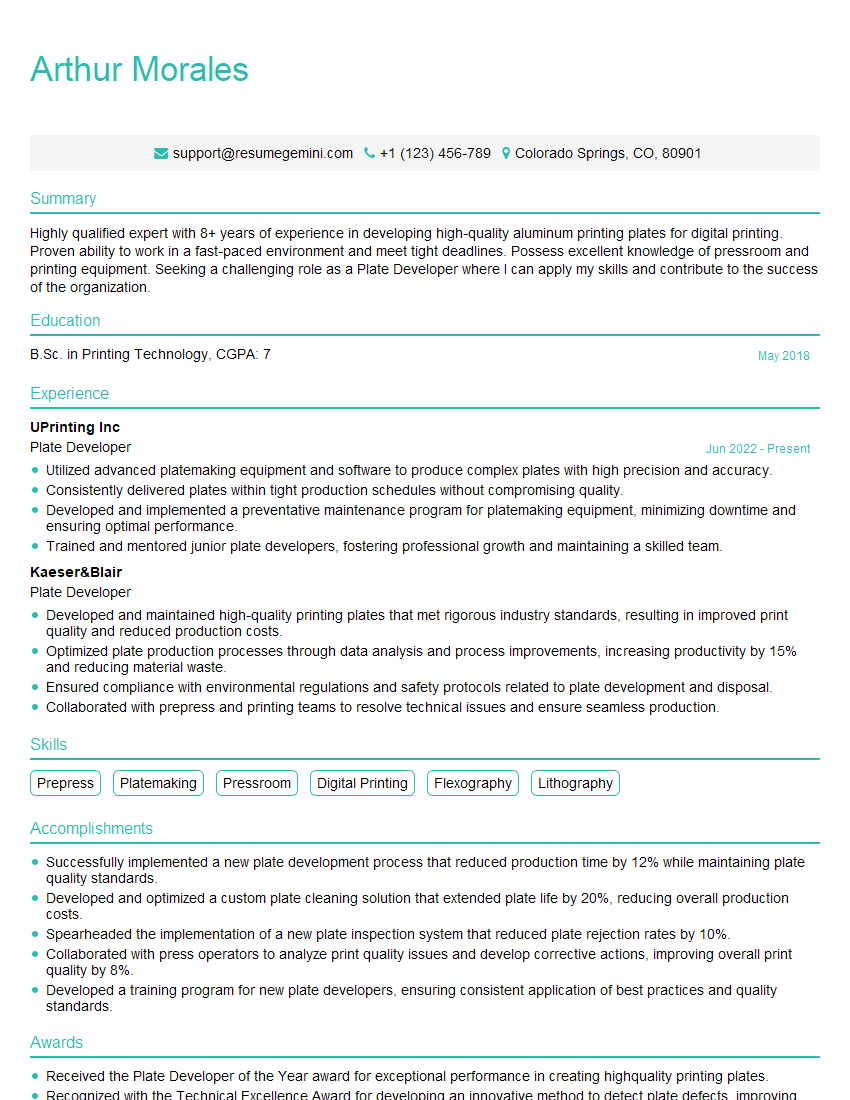

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plate Developer

1. Explain the process of creating a printing plate?

The process of creating a printing plate involves several steps:

- Prepress: Digital or analog files are prepared, color-separated, and imposed.

- Imaging: The image is transferred onto a photosensitive plate using a laser or other imaging device.

- Exposure: The plate is exposed to ultraviolet light, which hardens the areas corresponding to the image.

- Development: The unexposed areas of the plate are washed away, leaving the image areas intact.

- Finishing: The plate is baked or cured to enhance its durability and resistance to wear.

2. What are the different types of printing plates?

Metal plates:

- Durable and long-lasting

- Suitable for high-volume print runs

Polymer plates:

- Flexible and less expensive than metal plates

- Ideal for short to medium-run printing

Digital plates:

- Computer-to-plate (CTP) technology eliminates the need for film

- Fast and efficient for on-demand printing

3. What factors affect the quality of a printing plate?

The quality of a printing plate is influenced by several factors, including:

- Resolution: The higher the resolution, the sharper and more detailed the image will be.

- Exposure: Proper exposure ensures that the image areas are hardened adequately while the unexposed areas are removed completely.

- Plate material: The type of plate material (metal, polymer, digital) affects its durability, flexibility, and print quality.

- Platemaking equipment: The quality of the imaging and development processes can impact the plate’s accuracy and performance.

4. How do you troubleshoot common platemaking problems?

Common platemaking problems include:

- Dot gain: Excess ink spread on the plate, resulting in a loss of detail.

- Slurring: Smudging or bleeding of the image on the plate.

- Ghosting: A faint or unwanted image appearing on the plate.

- Scratches or dents: Physical damage to the plate that can affect print quality.

- Plate wear: Deterioration of the plate over time, reducing its lifespan.

5. What are the latest trends in platemaking technology?

- Automation: Automated platemaking systems improve efficiency and reduce labor costs.

- Digital platemaking: CTP technology eliminates the need for film and reduces production time.

- Environmentally friendly plates: Plates that are recyclable or biodegradable reduce environmental impact.

- Nanotechnology: Advanced coatings and materials enhance plate durability and print performance.

- 3D printing: Emerging technology for creating custom or complex printing plates.

6. Describe your experience in operating platemaking equipment.

In my previous role, I was responsible for operating and maintaining a range of platemaking equipment, including:

- Computer-to-plate (CTP) systems

- Exposure units

- Plate processors

- Baking ovens

I am proficient in setting up, calibrating, and operating these machines to ensure the production of high-quality printing plates.

7. Explain the importance of plate quality control.

- Consistency: Ensures consistent print quality across multiple presses and print runs.

- Waste reduction: Minimizes plate remakes and spoilage due to defects.

- Press efficiency: Well-made plates run smoothly on presses, reducing downtime and increasing productivity.

- Customer satisfaction: High-quality plates produce sharp and vibrant prints, meeting customer expectations.

- Reputation: A reputation for producing consistently high-quality plates builds customer loyalty and industry credibility.

8. What software do you use for platemaking?

- Prepress software: Adobe Creative Suite, CorelDRAW

- Platemaking software: Heidelberg Prinect, Kodak Prinergy

- RIP software: Caldera VisualRIP, EFI Fiery

I am proficient in using these software tools to create, edit, and output plate files.

9. Describe a challenging platemaking project you have worked on.

One challenging platemaking project I encountered involved printing a complex image with tight registration tolerances. To achieve the desired accuracy, I carefully calibrated the CTP system, optimized the exposure settings, and used a high-resolution plate.

Through meticulous attention to detail and collaboration with the pressroom, I was able to produce plates that met the demanding requirements and resulted in a successful print run.

10. How do you stay updated on the latest platemaking technologies and best practices?

- Industry conferences and exhibitions: Attend events like Graph Expo and drupa to learn about new products and advancements.

- Trade publications: Read industry magazines and online resources to stay informed about technical developments.

- Online training and webinars: Participate in online courses and webinars offered by platemaking equipment manufacturers and industry organizations.

- Networking with peers: Connect with other professionals in the field to exchange knowledge and insights.

- Research and experimentation: Stay curious and explore new technologies and techniques to improve platemaking processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plate Developer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plate Developer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The plate developer is responsible for preparing, processing, and developing photographic plates for use in printing. They work with a variety of equipment, including platemaking machines, developers, and fixers. The plate developer must have a good understanding of photographic chemistry and be able to follow instructions carefully.

1. Prepare photographic plates

The plate developer prepares photographic plates by cleaning them and applying a light-sensitive emulsion. The emulsion is then dried and the plate is ready to be exposed to light.

- Clean photographic plates

- Apply light-sensitive emulsion

2. Process photographic plates

Once the photographic plate has been exposed to light, it is processed to develop the image. The plate is placed in a developer solution, which converts the exposed silver halide crystals to metallic silver. The plate is then washed and fixed to stop the development process.

- Place photographic plate in developer solution

- Wash and fix photographic plate

3. Inspect photographic plates

The plate developer inspects the finished photographic plates to ensure that they are of good quality. The plates are checked for defects such as scratches, dirt, or uneven development. The plate developer also checks the density of the image to ensure that it is within the correct range.

- Inspect photographic plates for defects

- Check density of image

4. Maintain equipment

The plate developer is responsible for maintaining the equipment used in the platemaking process. This includes cleaning and calibrating the equipment, and replacing parts as needed. The plate developer must also be able to troubleshoot problems with the equipment.

- Clean and calibrate equipment

- Replace parts as needed

- Troubleshoot problems with equipment

Interview Tips

Here are some tips to help you ace your plate developer interview:

1. Research the company and the position

Before you go on your interview, be sure to do your research on the company and the position you are applying for. This will help you understand the company’s culture and values, and the specific requirements of the job. You should also be prepared to answer questions about your experience and qualifications.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work in the industry

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer questions

- Be specific and provide examples

- Tailor your answers to the job you are applying for

3. Prepare questions to ask the interviewer

Asking thoughtful questions at the end of your interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the job. Some good questions to ask include “What are the biggest challenges facing the company right now?” and “What are the opportunities for advancement within the company?”

- Ask questions about the company’s culture

- Ask questions about the job itself

- Ask questions about the team you would be working with

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you respect the interviewer and the company. You should also be prepared to answer questions about your experience and qualifications.

- Dress in business attire

- Arrive on time for your interview

- Be prepared to answer questions about your experience and qualifications

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plate Developer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!