Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plate Heating, Rolling, and Finishing Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

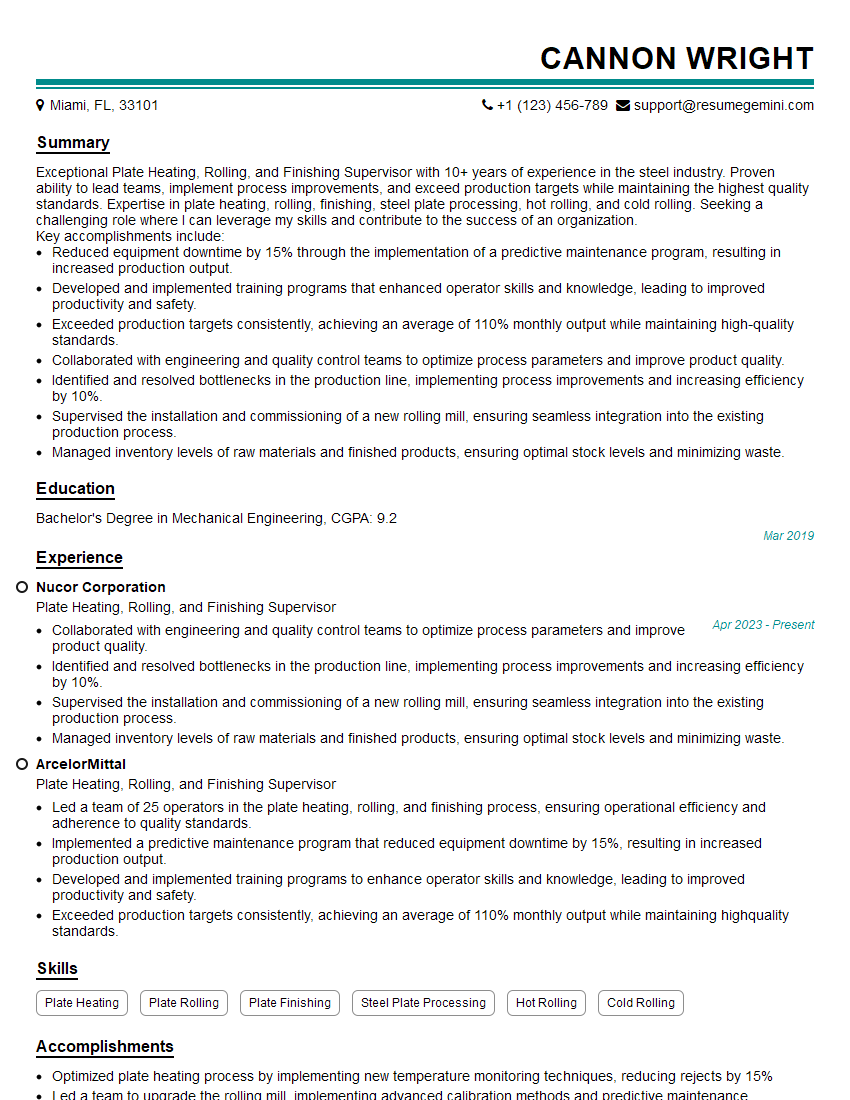

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plate Heating, Rolling, and Finishing Supervisor

1. What are the critical parameters to monitor during plate heating?

Answer: Monitoring the following parameters is crucial during plate heating:

- Furnace temperature

- Soaking time

- Plate temperature uniformity

- Decarburization and oxidation levels

- Furnace atmosphere composition

2. Describe the different types of plate rolling processes and their applications.

Hot Rolling

- Used for high-strength and wear-resistant plates

- Involves rolling plates at temperatures above their recrystallization point

Cold Rolling

- Used for precision and dimensional accuracy

- Involves rolling plates at room temperature, resulting in hardening

3. What are the common defects encountered in plate rolling and how can they be minimized?

Answer: Common defects in plate rolling include:

- Edge cracks: Caused by high rolling forces or uneven heating

- Surface defects: Caused by scale, rolling marks, or inclusions

- Camber: Caused by uneven rolling or material properties

- Defects can be minimized by proper furnace heating, controlled rolling forces, and optimal material selection

4. Discuss the role of cooling in plate finishing and its effects on plate properties.

Answer: Cooling plays a crucial role in plate finishing:

- Controlled cooling rates influence grain structure and mechanical properties

- Rapid cooling (quenching) increases hardness and strength but reduces toughness

- Slow cooling (annealing) promotes grain growth, improves toughness, but reduces hardness

- Appropriate cooling methods are selected based on desired plate properties

5. What are the different types of plate finishes and their respective advantages?

- Mill finish: Standard finish with a slightly rough surface

- Cold-rolled finish: Smooth and shiny surface with high dimensional accuracy

- Shot-blasted finish: Rougher surface with increased adhesion for coatings

- Pickled finish: Chemically treated surface for removing scale and rust

6. What are the safety protocols that must be followed in a plate heating, rolling, and finishing facility?

- Proper protective gear (gloves, safety glasses, earplugs)

- Clear communication and signaling during operations

- Regular equipment inspections and maintenance

- Emergency response plans and training

- Compliance with industry regulations and standards

7. Describe the role of automation in modern plate heating, rolling, and finishing processes.

- Automated temperature control systems for precise heating

- Computerized rolling mills for accurate and efficient rolling

- Automatic cooling systems for controlled plate properties

- Automated finishing lines for consistent quality

- Data collection and analysis for process optimization

8. How do you ensure quality control in plate heating, rolling, and finishing operations?

- Regular testing and inspection of plates at various stages

- Calibration and maintenance of equipment to minimize errors

- Non-destructive testing methods (e.g., ultrasonic, eddy current)

- Compliance with industry standards and specifications

- Feedback and continuous improvement based on data analysis

9. What are the latest trends and developments in plate heating, rolling, and finishing technologies?

- High-strength and lightweight materials for improved performance

- Advanced heating methods for energy efficiency and reduced emissions

- Closed-loop control systems for real-time process optimization

- Artificial intelligence and machine learning for predictive maintenance

- Sustainable and environmentally friendly practices

10. How do you stay updated with the advancements in plate heating, rolling, and finishing technologies?

- Attending industry conferences and workshops

- Reading technical journals and publications

- Networking with peers and professionals

- Participating in vendor training and webinars

- Seeking opportunities for professional development

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plate Heating, Rolling, and Finishing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plate Heating, Rolling, and Finishing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Plate Heating, Rolling, and Finishing Supervisor is responsible for overseeing the entire plate production process, from heating and rolling to finishing and packaging. They play a vital role in ensuring that the plates meet the required specifications and are delivered to customers on time.

1. Heating

The supervisor is responsible for ensuring that the plates are heated to the correct temperature before rolling. This involves monitoring the temperature of the plates and adjusting the heating equipment accordingly.

- Operate and maintain plate heating furnaces or ovens

- Monitor and control plate temperature during heating

2. Rolling

Once the plates have been heated, they are rolled to reduce their thickness and achieve the desired shape. The supervisor is responsible for overseeing this process and making sure that the plates are rolled to the correct thickness and width.

- Operate and maintain plate rolling mills

- Monitor and control rolling parameters such as speed, pressure, and temperature

3. Finishing

After rolling, the plates are finished to improve their surface quality and properties. The supervisor is responsible for overseeing this process and ensuring that the plates meet the required specifications.

- Supervise plate finishing operations such as trimming, cutting, and edge preparation

- Inspect and approve finished plates

4. Packaging and Shipping

Once the plates have been finished, they are packaged and shipped to customers. The supervisor is responsible for ensuring that the plates are packaged correctly and are shipped on time.

- Plan and coordinate plate packaging and shipping

- Ensure that plates are packaged and shipped in compliance with regulations

Interview Tips

To ace the interview for the Plate Heating, Rolling, and Finishing Supervisor position, it is important to prepare thoroughly and to highlight your skills and experience in the following areas:

1. Technical Skills

You should have a strong understanding of the plate production process, including heating, rolling, finishing, and packaging. You should also be familiar with the equipment used in these processes and be able to troubleshoot any problems that may arise.

- Research the company and the specific plate production process they use.

- Be prepared to discuss your experience in operating and maintaining plate heating furnaces, rolling mills, and other finishing equipment.

2. Leadership Skills

As a supervisor, you will be responsible for leading and motivating a team of production workers. You should have strong leadership skills and be able to create a positive and productive work environment.

- Highlight your experience in leading and motivating teams, and provide examples of how you have successfully done so in the past.

- Discuss your approach to conflict resolution and how you would handle a situation in which team members are not working well together.

3. Problem-Solving Skills

The plate production process can be complex and there are often problems that can arise. You should have strong problem-solving skills and be able to identify and resolve problems quickly and efficiently.

- Describe your problem-solving process and provide examples of how you have successfully solved problems in the past.

- Discuss your experience in troubleshooting and repairing plate production equipment.

4. Communication Skills

You will need to be able to communicate effectively with a variety of stakeholders, including production workers, engineers, and customers. You should be able to clearly and concisely explain technical information and be able to build and maintain positive relationships.

- Provide examples of how you have effectively communicated with different stakeholders in the past, including both technical and non-technical audiences.

- Discuss your experience in developing and delivering presentations.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plate Heating, Rolling, and Finishing Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plate Heating, Rolling, and Finishing Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.