Feeling lost in a sea of interview questions? Landed that dream interview for Plate Printer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plate Printer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

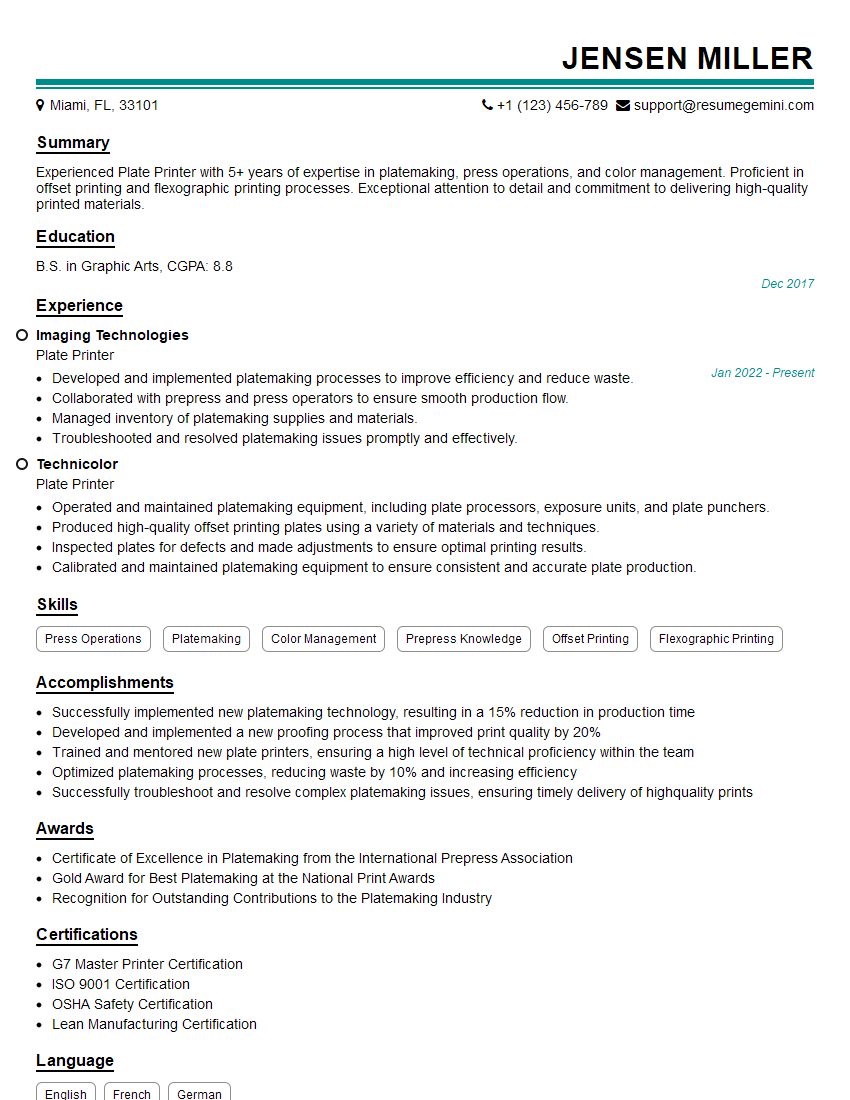

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plate Printer

1. What are the different types of printing plates used in the industry and their advantages and disadvantages?

- Photopolymer Plates:

- Advantages: High-quality prints, Flexible, Durable

- Disadvantages: Requires special equipment, Can be expensive

- Metal Plates:

- Advantages: Durable, Long-lasting, High-volume printing

- Disadvantages: Heavy, Can corrode, Expensive

- Rubber Plates:

- Advantages: Versatile, Flexible, Cost-effective

- Disadvantages: Not as durable, Not suitable for high-volume printing

2. Explain the process of creating a printing plate from a digital file.

Prepress:

- Creating a digital file of the image or text to be printed.

- Converting the digital file into a format compatible with the platemaking equipment.

Platemaking:

- Imaging the digital file onto a photosensitive plate.

- Developing the plate to create the printing areas.

- Finishing the plate by adding a protective coating.

3. How do you ensure the accuracy and quality of the printed images?

- Calibrating the printing equipment regularly.

- Using high-quality plates and inks.

- Proofing the printed images before mass production.

- Inspecting the printed products for defects.

4. What are the common problems encountered during the plate printing process and how do you troubleshoot them?

- Image distortion: Adjust plate tension, check plate alignment.

- Uneven ink distribution: Clean ink rollers, adjust ink flow.

- Scratches or streaks on the printed image: Inspect plates for damage, clean printing blankets.

- Ghosting or double images: Check plate registration, adjust printing pressure.

5. How do you maintain and clean the plate printing equipment?

- Regularly cleaning the printing rollers and blankets.

- Inspecting and replacing worn-out parts.

- Calibrating the equipment to ensure accurate printing.

- Following manufacturer’s maintenance guidelines.

6. Describe your experience in working with different printing materials.

In my previous role, I worked with a variety of printing materials, including paper, vinyl, and fabric. I have extensive experience in printing on different types of paper, including coated, uncoated, and textured paper. I am also proficient in printing on vinyl banners, stickers, and decals. Additionally, I have experience in printing on fabric using sublimation and direct-to-fabric printing techniques.

7. How do you handle high-volume printing jobs?

- Plan and schedule printing jobs efficiently to meet deadlines.

- Use automated equipment and processes to increase productivity.

- Monitor print quality and make adjustments as needed.

- Collaborate with the production team to ensure smooth operation.

8. What is your understanding of color management in printing?

- Color management involves controlling and matching colors throughout the printing process.

- It includes calibrating equipment, using color profiles, and understanding color theory.

- By managing colors effectively, I can ensure accurate and consistent color reproduction in printed products.

9. Describe your experience in using printing software and equipment.

I am proficient in using various printing software and equipment, including Adobe Creative Suite, RIP software, and digital printing presses. I have experience in creating and preparing digital files for printing, managing color profiles, and operating printing equipment to produce high-quality prints. Additionally, I am familiar with different printing techniques, such as offset printing, digital printing, and large format printing.

10. What are the safety measures to be followed while working in a printing environment?

- Wearing appropriate safety gear, such as gloves and safety glasses.

- Following proper handling procedures for printing materials and chemicals.

- Maintaining a clean and organized work area.

- Being aware of potential hazards, such as sharp objects and moving machinery.

- Following emergency protocols in case of accidents or spills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plate Printer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plate Printer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plate Printers are highly skilled professionals responsible for creating and printing high-quality printing plates used in various printing processes. Their key job responsibilities include:

1. Plate Preparation

Prepare printing plates by cleaning, sensitizing, and coating them with photo emulsion or other materials.

- Select and prepare appropriate printing plates based on the job requirements.

- Clean and inspect plates to ensure they are free of defects and contaminants.

2. Plate Imaging

Expose printing plates to light or laser to create the desired image. Develop and process exposed plates to create a permanent image.

- Operate plate exposure units to expose plates to light or laser according to specified parameters.

- Develop and process exposed plates using chemicals and equipment to create a durable image.

3. Plate Maintenance

Inspect and maintain printing plates to ensure their quality and longevity. Repair or replace damaged plates as needed.

- Inspect plates for defects, scratches, or other damage and take corrective actions.

- Repair or replace damaged plates using specialized techniques and equipment.

4. Quality Control

Monitor the printing process to ensure the plates are producing high-quality prints. Make adjustments to plates or equipment as needed.

- Monitor print quality and make necessary adjustments to plates or equipment to achieve optimal results.

- Troubleshoot printing issues and identify the root cause to prevent recurrence.

Interview Tips

To ace your Plate Printer interview, consider the following tips:

1. Research the Company and Position

Gather information about the company’s history, culture, and the specific role you’re applying for. This will help you understand their expectations and tailor your answers accordingly.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on trends and best practices.

2. Highlight Your Technical Skills

Emphasize your proficiency in plate preparation, imaging, and maintenance techniques. Provide specific examples of projects where you demonstrated your skills.

- Describe your experience with different types of printing plates and how you handled specific challenges.

- Showcase your knowledge of plate exposure and development processes.

3. Demonstrate Your Attention to Detail

Plate Printers must be meticulous and have a keen eye for detail. Highlight your ability to inspect plates carefully and identify even small defects.

- Explain how you ensure the accuracy and quality of your work.

- Provide examples of how you have identified and resolved printing issues caused by plate defects.

4. Emphasize Your Troubleshooting Abilities

Printing processes can sometimes encounter problems. Demonstrate your ability to troubleshoot and resolve issues efficiently.

- Describe a situation where you diagnosed and fixed a printing problem related to plates.

- Explain your approach to identifying the root cause of issues and implementing solutions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plate Printer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!