Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plate Sensitizer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plate Sensitizer so you can tailor your answers to impress potential employers.

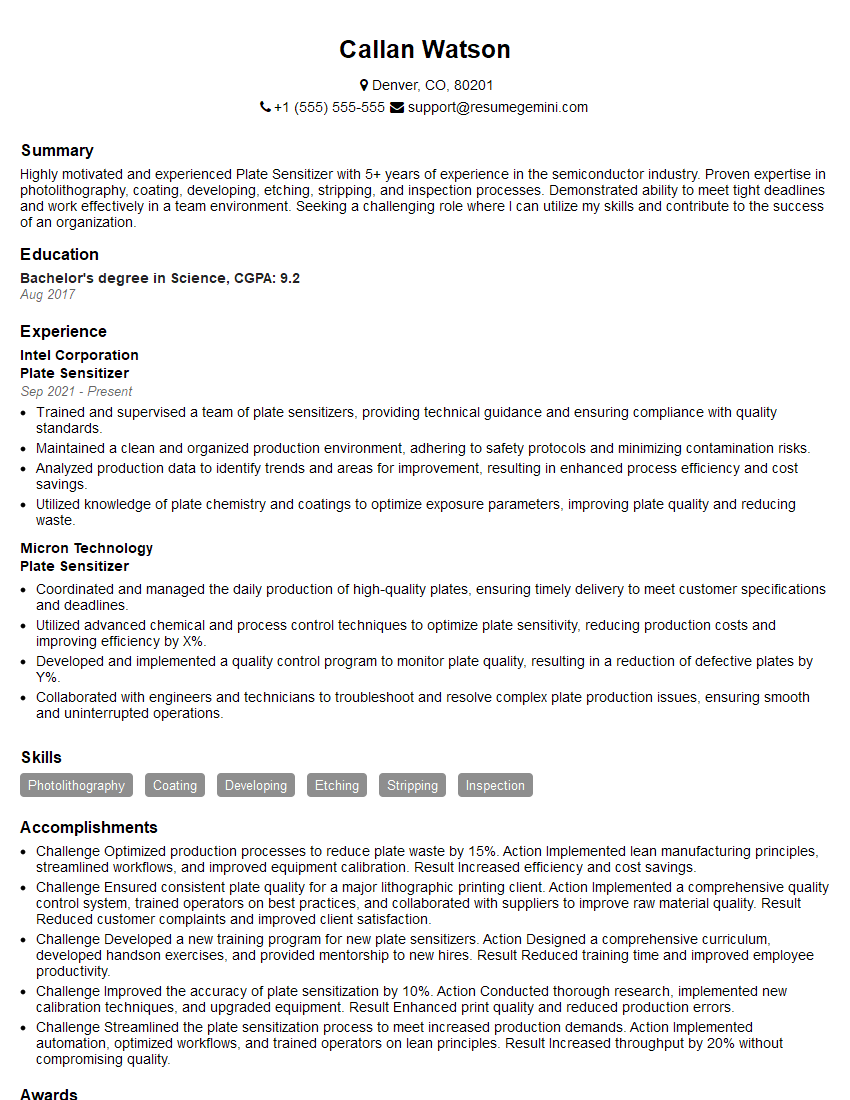

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plate Sensitizer

1. What are the different types of plate sensitizers used in flexography?

There are three main types of plate sensitizers used in flexography:

- Diazonium salts

- Azide compounds

- Carbene generators

2. What is the difference between a positive-working and a negative-working plate sensitizer?

Positive-working plate sensitizer

- Creates an image area that is receptive to ink

- Areas exposed to light become hydrophilic

Negative-working plate sensitizer

- Creates an image area that is receptive to water

- Areas exposed to light become hydrophobic

3. What are the factors that affect the sensitivity of a plate sensitizer?

The sensitivity of a plate sensitizer is affected by several factors, including:

- The type of sensitizer

- The concentration of the sensitizer

- The exposure time

- The wavelength of the light source

4. How do you determine the optimum exposure time for a plate sensitizer?

The optimum exposure time for a plate sensitizer can be determined by performing a series of tests using a sensitometer. A sensitometer is a device that exposes a plate to a range of light intensities and exposure times. The resulting plate is then processed and the image area is evaluated to determine the optimum exposure time.

5. What are the precautions that should be taken when handling plate sensitizers?

Plate sensitizers are typically hazardous materials and should be handled with care. Precautions that should be taken when handling plate sensitizers include:

- Wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and a respirator

- Working in a well-ventilated area

- Avoiding contact with skin and eyes

- Storing plate sensitizers in a cool, dark place

6. What are the different methods used to apply plate sensitizers?

Plate sensitizers can be applied to plates using a variety of methods, including:

- Brushing

- Coating

- Spraying

7. What are the advantages and disadvantages of using a positive-working plate sensitizer?

Advantages:

- Higher image quality

- Wider exposure latitude

- Less sensitive to contamination

Disadvantages:

- More expensive

- Requires a more complex development process

8. What are the advantages and disadvantages of using a negative-working plate sensitizer?

Advantages:

- Less expensive

- Simpler development process

- More tolerant of overexposure

Disadvantages:

- Lower image quality

- Narrower exposure latitude

- More sensitive to contamination

9. What is the role of a plate sensitizer in the flexographic printing process?

A plate sensitizer is a chemical solution that is applied to a printing plate to make it sensitive to light. When the plate is exposed to light, the sensitizer reacts to create a hydrophilic (water-loving) image area. This image area is then able to accept ink, while the non-image area (which has not been exposed to light) remains hydrophobic (water-repellent) and will not accept ink.

10. What are the different types of light sources used in flexographic platemaking?

The most common types of light sources used in flexographic platemaking are:

- Metal halide lamps

- UV lamps

- LED lamps

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plate Sensitizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plate Sensitizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plate Sensitizer plays a crucial role in the production process of printed materials, ensuring the proper transfer of images from digital or physical formats to plates used in offset printing. The key job responsibilities encompass:

1. Plate Preparation

Preparing printing plates by cleaning, coating, and drying them to create a receptive surface for image transfer.

- Cleaning plates with solvents and other chemicals to remove any contaminants or residues.

- Coating plates with photosensitive emulsions or films to create a light-sensitive surface.

- Drying plates under controlled conditions to ensure proper adhesion of the emulsion or film.

2. Image Transfer

Transferring digital or physical images onto prepared plates using specialized equipment.

- Exposing plates to light through negatives or digital files to create a latent image.

- Developing plates using chemical baths or processors to make the latent image visible.

- Rinsing and drying plates to remove any residual chemicals.

3. Quality Control

Inspecting plates to ensure they meet quality standards and specifications.

- Verifying the sharpness, clarity, and accuracy of images transferred to plates.

- Identifying and correcting any defects or errors in the platemaking process.

- Maintaining records and documentation to ensure traceability and adherence to quality control procedures.

4. Equipment Maintenance

Maintaining and calibrating platemaking equipment to ensure optimal performance.

- Cleaning, lubricating, and adjusting platemakers, processors, and other equipment.

- Calibrating equipment to ensure accurate image transfer and exposure.

- Troubleshooting and resolving equipment issues to minimize downtime.

Interview Tips

To prepare effectively for a Plate Sensitizer interview, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s profile, the specific role and responsibilities, and the industry trends to demonstrate your interest and knowledge.

2. Highlight Relevant Experience and Skills

Emphasize your experience in plate preparation, image transfer, quality control, and equipment maintenance related to the printing industry.

- Provide specific examples of your accomplishments and how they impacted the efficiency or quality of the platemaking process.

- Quantify your results whenever possible to demonstrate your effectiveness.

3. Practice Common Interview Questions

Anticipate and prepare for common interview questions, such as:

- “Tell us about your experience in plate sensitization and the techniques you use.”

- “Describe a situation where you had to troubleshoot and resolve an issue with platemaking equipment.”

- “How do you ensure the accuracy and quality of the images transferred to plates?”

4. Be Enthusiastic and Professional

Show your enthusiasm for the field and express your interest in the position. Dress appropriately, arrive on time, and maintain a positive and confident demeanor throughout the interview.

5. Ask Informed Questions

Ask insightful questions about the company, the role, and the industry to indicate your engagement and curiosity. This also provides an opportunity to clarify any uncertainties and show your interest in the long-term prospects.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plate Sensitizer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!