Are you gearing up for an interview for a Plateman position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Plateman and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

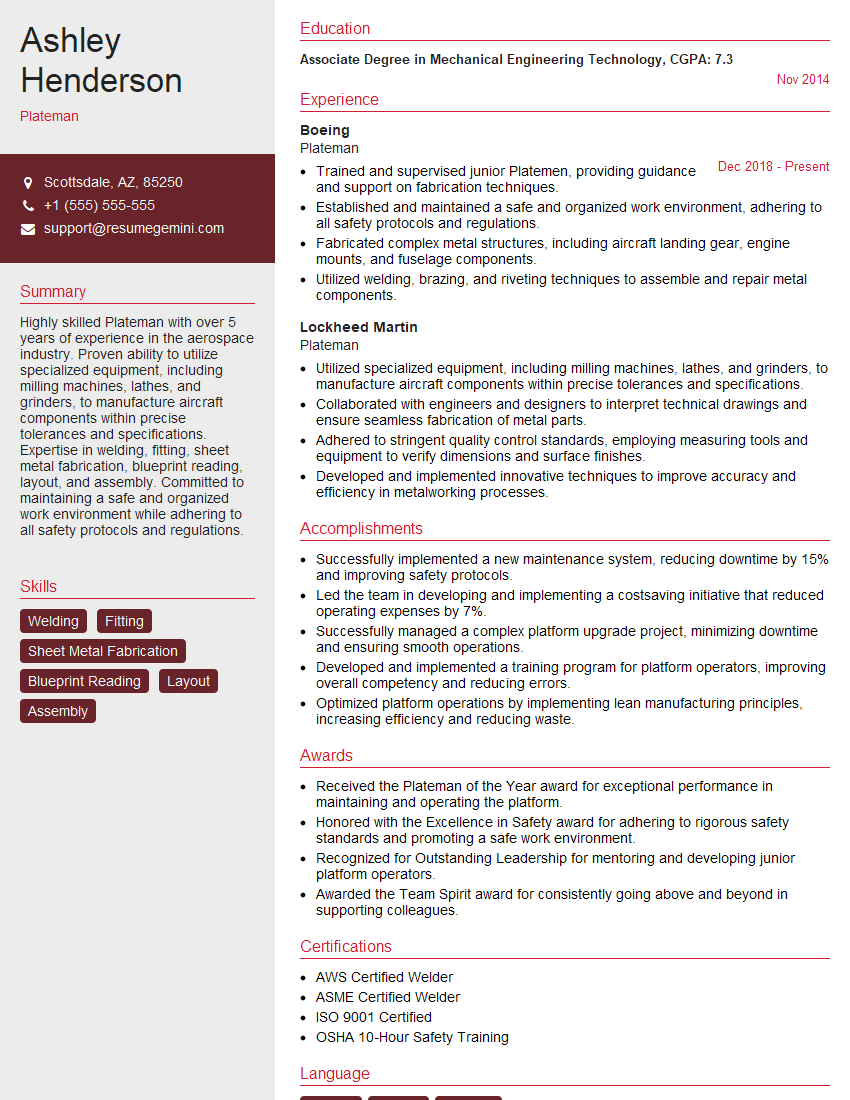

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plateman

1. Can you describe the process of heat treating a metal plate?

- Annealing: It is a process of heating the metal plate to a high temperature and then slowly cooling it. Annealing makes the metal plate softer and more ductile.

- Normalizing: It is a process of heating the metal plate to a high temperature and then cooling it in air. Normalizing makes the metal plate stronger and harder than annealing.

- Hardening: It is a process of heating the metal plate to a high temperature and then cooling it rapidly. Hardening makes the metal plate very hard and brittle.

- Tempering: It is a process of heating the metal plate to a temperature below the hardening temperature and then cooling it slowly. Tempering makes the metal plate less hard and more ductile.

2. What is the difference between a hot rolled and a cold rolled steel plate?

Hot rolled steel plate

- Hot rolled steel plate is produced by rolling steel at a high temperature.

- Hot rolled steel plate has a rough surface and is not as strong as cold rolled steel plate.

- Hot rolled steel plate is less expensive than cold rolled steel plate.

Cold rolled steel plate

- Cold rolled steel plate is produced by rolling steel at room temperature.

- Cold rolled steel plate has a smooth surface and is stronger than hot rolled steel plate.

- Cold rolled steel plate is more expensive than hot rolled steel plate.

3. What are the different types of welding processes?

- Arc welding: Arc welding is a process that uses an electric arc to melt the metal plates together.

- MIG welding: MIG welding is a type of arc welding that uses a consumable electrode.

- TIG welding: TIG welding is a type of arc welding that uses a non-consumable electrode.

- Plasma welding: Plasma welding is a type of arc welding that uses a plasma torch to melt the metal plates together.

- Laser welding: Laser welding is a process that uses a laser to melt the metal plates together.

4. What are the different types of cutting processes?

- Plasma cutting: Plasma cutting is a process that uses a plasma torch to cut the metal plates.

- Laser cutting: Laser cutting is a process that uses a laser to cut the metal plates.

- Water jet cutting: Water jet cutting is a process that uses a high-pressure water jet to cut the metal plates.

- Shear cutting: Shear cutting is a process that uses a shear to cut the metal plates.

5. What are the different types of forming processes?

- Bending: Bending is a process that uses a press to bend the metal plates.

- Rolling: Rolling is a process that uses a roller to roll the metal plates.

- Forging: Forging is a process that uses a hammer to shape the metal plates.

- Extrusion: Extrusion is a process that uses a die to force the metal plates through a shape.

6. What are the different types of surface treatments?

- Painting: Painting is a process that uses a paint to coat the metal plates.

- Plating: Plating is a process that uses a metal to coat the metal plates.

- Anodizing: Anodizing is a process that uses an electrochemical process to create a protective oxide layer on the metal plates.

7. What are the different types of quality control tests?

- Visual inspection: Visual inspection is a process that uses the human eye to inspect the metal plates.

- Dimensional inspection: Dimensional inspection is a process that uses a measuring device to inspect the metal plates.

- Non-destructive testing: Non-destructive testing is a process that uses a non-destructive method to inspect the metal plates.

8. What are the different types of safety procedures?

- Wearing personal protective equipment: Personal protective equipment includes items such as safety glasses, gloves, and earplugs.

- Using proper tools and equipment: Using proper tools and equipment helps to prevent accidents.

- Following safety procedures: Following safety procedures helps to prevent accidents.

9. What are the different types of environmental regulations?

- Air pollution regulations: Air pollution regulations limit the amount of pollutants that can be released into the air.

- Water pollution regulations: Water pollution regulations limit the amount of pollutants that can be released into the water.

- Solid waste regulations: Solid waste regulations limit the amount of solid waste that can be disposed of.

10. What are the different types of quality management systems?

- ISO 9001: ISO 9001 is a quality management system that is used to improve the quality of products and services.

- AS9100: AS9100 is a quality management system that is used in the aerospace industry.

- IATF 16949: IATF 16949 is a quality management system that is used in the automotive industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plateman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plateman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plateman is an important member of the team in a metalworking or manufacturing environment. They are responsible for operating and maintaining the platen machine and associated equipment, ensuring that the production process runs smoothly and efficiently.

1. Machine Operation

The Plateman is responsible for the safe and efficient operation of the platen machine. This includes:

- Setting up and adjusting the machine according to specifications.

- Loading and unloading materials into and out of the machine.

- Monitoring the machine during operation and making any necessary adjustments.

- Performing maintenance and repairs on the machine as needed.

2. Material Handling

The Plateman is also responsible for handling materials in the work area. This includes:

- Loading and unloading materials from trucks and other vehicles.

- Moving materials around the work area using forklifts or other equipment.

- Storing materials in a safe and organized manner.

3. Quality Control

The Plateman is responsible for ensuring that the products produced by the platen machine meet quality standards. This includes:

- Inspecting products for defects and making any necessary corrections.

- Maintaining records of product quality.

- Working with other team members to improve product quality.

4. Safety

The Plateman is responsible for maintaining a safe work environment. This includes:

- Following all safety procedures and regulations.

- Identifying and eliminating hazards in the work area.

- Responding to emergencies in a safe and effective manner.

Interview Tips

Preparing for an interview for a Plateman position can be a bit daunting, but by following these tips, you can increase your chances of success:

1. Research the Company and the Position

Take some time to learn about the company you’re applying to and the Plateman position. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work at the company.

- Review the job description carefully.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked in a Plateman interview. It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently during the interview.

- Tell me about your experience operating a platen machine.

- What are your strengths and weaknesses as a Plateman?

- Why are you interested in working for our company?

- What are your salary expectations?

3. Be Prepared to Talk About Your Safety Knowledge

Safety is a top priority in any manufacturing environment. In your interview, you’ll likely be asked questions about your safety knowledge and experience. Be prepared to discuss your knowledge of safety regulations and procedures.

- What are some of the most important safety regulations that you’re familiar with?

- What are some of the most common hazards in a metalworking environment?

- How would you respond to a safety emergency?

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally for your interview. Also, be sure to arrive on time. Being late for an interview is a major turn-off for employers.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your clothes are clean and pressed.

- Arrive for your interview at least 15 minutes early.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Plateman role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.