Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Platen Press Operator Apprentice interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Platen Press Operator Apprentice so you can tailor your answers to impress potential employers.

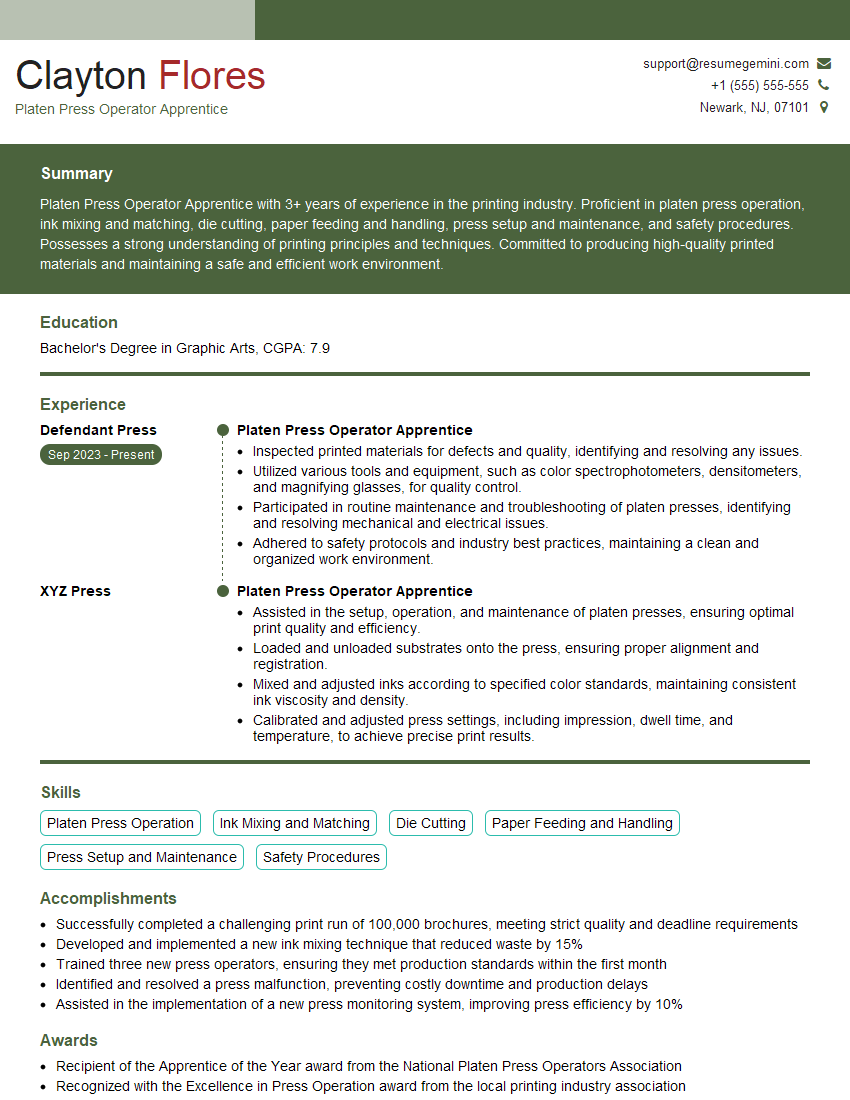

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Platen Press Operator Apprentice

1. Describe the process of loading paper into a platen press.

The process of loading paper into a platen press involves the following steps:

- Select the appropriate paper size and weight for the project.

- Remove any previous paper from the press bed and make sure the bed is clean.

- Align the paper guides on the press bed to match the paper size.

- Place the paper on the press bed, making sure that the edges are aligned with the guides.

- Lower the platen and apply pressure to hold the paper in place.

2. How do you ensure accurate registration when printing on a platen press?

Proper Platen Press Setup

- Ensure the platen press is level and properly calibrated.

- Check that the paper guides are adjusted correctly for the paper size.

- Align the printing plate precisely on the press bed.

Precise Paper Handling

- Load paper into the press carefully to avoid skewing.

- Use a slip sheet to prevent ink smudging.

- Apply consistent pressure to the paper during printing.

3. What are the common troubleshooting steps for print defects such as ghosting or ink piling?

Ghosting

- Check if the ink is too thin or the impression is too light.

- Adjust the ink viscosity or impression pressure accordingly.

- Use a suitable paper type that absorbs ink well.

Ink Piling

- Check if the ink is too thick or the impression is too heavy.

- Adjust the ink viscosity or impression pressure as needed.

- Inspect the printing plate for any damage or debris.

4. How do you maintain and clean a platen press to ensure optimal performance?

Regular maintenance and cleaning are crucial for optimal platen press performance. The following steps should be followed:

- Clean the press bed and platen regularly to remove ink and paper debris.

- Lubricate moving parts as per the manufacturer’s instructions.

- Inspect and clean the ink rollers and fountain to prevent ink buildup.

- Calibrate the press periodically to ensure accurate registration and pressure settings.

5. Can you describe the different types of platen presses and their applications?

Hand-operated Platen Press

- Compact and suitable for small-scale printing.

- Manual operation requires physical effort.

Power-operated Platen Press

- Motorized operation provides greater efficiency.

- Capable of handling larger print runs and thicker materials.

Automatic Platen Press

- Fully automated operation with programmable settings.

- Ideal for high-volume and precision printing.

6. What safety precautions should be taken when operating a platen press?

- Wear appropriate safety gear, including gloves and safety glasses.

- Ensure the press is properly grounded to prevent electrical hazards.

- Keep hands clear of moving parts during operation.

- Never reach under the platen while it is in motion.

- Follow proper lockout/tagout procedures before performing maintenance.

7. How do you calculate the impression pressure required for a specific printing job?

Impression pressure is determined based on:

- Paper thickness and density

- Type of ink used

- Desired print quality

- Press manufacturer’s specifications

The appropriate pressure can be calculated using formulas provided by the press manufacturer or through experimentation.

8. What are the factors that affect the quality of printed products from a platen press?

Press Condition

- Proper maintenance and calibration

- Cleanliness of the press bed and platen

Printing Materials

- Paper quality and suitability

- Ink viscosity and coverage

Operator Skills

- Precise registration and impression pressure settings

- Proper handling of paper and materials

9. How do you troubleshoot common operational issues with a platen press?

Paper Jams

- Check for misaligned paper guides or debris in the press.

- Adjust paper guides or remove obstructions.

Uneven Printing

- Inspect the printing plate for damage or debris.

- Clean the plate and adjust impression pressure as needed.

Ghosting or Ink Piling

- Adjust ink viscosity or impression pressure.

- Check for proper paper absorption and ink coverage.

10. Do you have any experience working with different paper stocks and printing techniques on a platen press?

Yes, I have experience working with various paper stocks, including bond, cardstock, and specialty papers. I am also proficient in different printing techniques such as letterpress, foil stamping, and embossing. My experience has equipped me with the skills to handle a wide range of printing projects and achieve high-quality results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Platen Press Operator Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Platen Press Operator Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Apprentice Platen Press Operator plays a vital role in the printing industry. Their primary responsibilities include:

1. Press Operation

Operate platen presses to produce high-quality printed materials such as letterheads, business cards, envelopes, and posters.

- Set up and adjust presses according to specifications.

- Load and unload paper and other materials.

2. Ink Mixing and Preparation

Mix and prepare inks to achieve the desired colors and consistency.

- Follow specified formulas and color guides.

- Adjust ink viscosity as needed.

3. Quality Control

Monitor press operations and inspect printed materials to ensure quality standards are met.

- Identify and correct defects in printing.

- Maintain press equipment to minimize downtime.

4. Safety and Housekeeping

Adhere to safety protocols and maintain a clean and organized work environment.

- Follow proper handling procedures for inks and solvents.

- Keep work area free of tripping hazards and debris.

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some tips to help candidates ace their interview for a Platen Press Operator Apprentice position:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and products/services. Research the specific role you are applying for and its responsibilities.

- Visit the company website and LinkedIn page.

- Read industry articles and news about the company.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers. Consider the key job responsibilities and think about how your skills and experience align with them.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Get feedback from a friend or family member on your answers.

3. Highlight Relevant Skills and Experience

Emphasize skills and experience that are relevant to the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact.

- Mention any prior experience with platen presses or printing equipment.

- Highlight your attention to detail and quality-oriented nature.

4. Show Enthusiasm and Eagerness

Conveying your enthusiasm for the position and the printing industry is essential. Express your interest in learning and growing within the organization.

- Ask thoughtful questions during the interview to show your engagement.

- Be positive and confident in your demeanor.

Next Step:

Now that you’re armed with the knowledge of Platen Press Operator Apprentice interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Platen Press Operator Apprentice positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini