Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plating Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

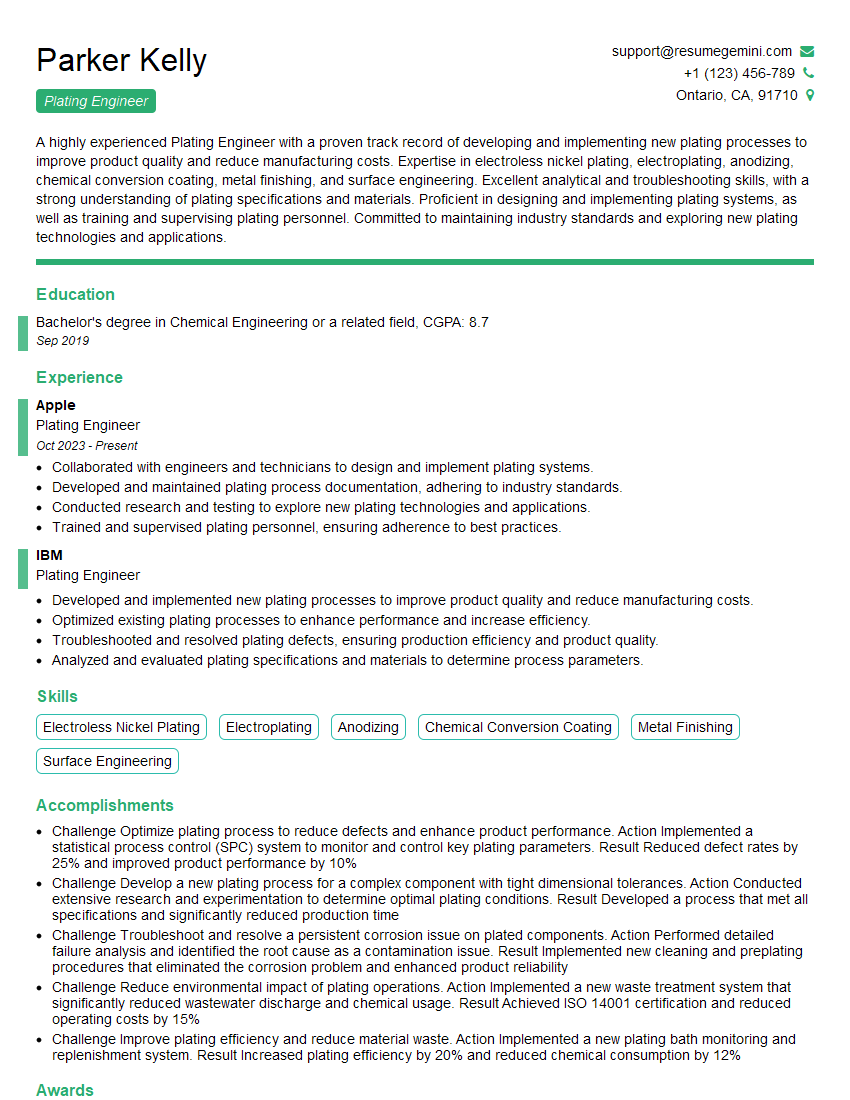

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plating Engineer

1. Describe the process of electroplating and its applications.

- Electroplating is an electrochemical process that uses an electric current to reduce metal ions in a solution and coat a conductive object with a thin layer of metal.

- It’s used in a variety of applications, including corrosion protection, wear resistance, electrical conductivity, and decorative purposes.

2. Explain the factors that influence the thickness and quality of an electroplated coating.

- Current density: Higher current density leads to thicker coatings.

- Solution concentration: Higher concentration of metal ions leads to thicker coatings.

- Temperature: Higher temperature increases the rate of deposition.

- Agitation: Agitation of the solution helps to prevent the formation of nodules and other defects.

- Substrate preparation: Proper cleaning and activation of the substrate ensures good adhesion of the coating.

3. How do you troubleshoot common plating problems like peeling, blistering, and discoloration?

- Peeling: Check for poor substrate preparation, high internal stress in the coating, or insufficient adhesion.

- Blistering: Check for trapped gases, impurities in the solution, or too rapid deposition.

- Discoloration: Check for improper cleaning of the substrate, contamination of the solution, or incorrect pH levels.

4. What are the different types of plating baths and their advantages and disadvantages?

- Acidic baths: Provide good throwing power and bright deposits, but can be corrosive.

- Alkaline baths: Less corrosive than acidic baths, but may yield duller deposits.

- Neutral baths: Offer a compromise between acidic and alkaline baths in terms of corrosion and deposit quality.

5. How do you optimize the plating process to minimize waste and environmental impact?

- Use efficient plating baths with high metal utilization.

- Control the solution temperature and agitation to minimize drag-out losses.

- Implement proper waste treatment and disposal systems.

- Use recycled or recovered materials whenever possible.

6. Describe the different methods for testing and evaluating the quality of electroplated coatings.

- Thickness measurement: Using micrometers, calipers, or non-destructive methods like X-ray fluorescence.

- Adhesion testing: Scratch tests, peel tests, or pull tests.

- Corrosion testing: Salt spray tests, humidity tests, or electrochemical impedance spectroscopy.

7. What are the emerging trends and technologies in the electroplating industry?

- Nanoplating: Deposition of ultrathin and uniform coatings with enhanced properties.

- Selective plating: Precise deposition on specific areas of a substrate.

- Additive manufacturing: Use of plating techniques in 3D printing to create complex and customized parts.

8. Describe your experience in designing and optimizing electroplating processes.

- Designed and implemented a new plating bath for improved corrosion resistance and wear performance.

- Optimized plating parameters to reduce waste and increase production efficiency.

- Developed a quality control system to ensure consistent coating quality.

9. How do you stay updated with the latest advancements in the plating industry?

- Attend industry conferences and trade shows.

- Read technical journals and research papers.

- Collaborate with experts in the field.

10. What are your strengths and weaknesses as a Plating Engineer?

- Strengths: Excellent understanding of electroplating principles, process optimization, and quality control.

- Weaknesses: Limited experience in some specialized plating techniques, but eager to learn and expand my knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plating Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plating Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plating Engineers are engineers who work in the plating industry. They are responsible for the design, development, and maintenance of plating processes, and for ensuring that the quality of the plated products meets or exceeds customer specifications.

1. Design and Development of Plating Processes

Plating Engineers design and develop new plating processes, or improve existing ones, in order to meet the needs of customers. They consider factors such as the type of metal or alloy to be plated, the substrate material, the desired thickness of the plating, and the environmental regulations that must be met.

- Conduct experiments to determine the optimum plating parameters, such as the concentration of the plating solution, the temperature of the plating bath, and the current density.

- Develop and maintain process specifications, which document the plating parameters and the quality control procedures that must be followed.

2. Maintenance of Plating Processes

Plating Engineers are responsible for maintaining the plating processes so that they operate within the specified parameters. They monitor the plating baths, and make adjustments as necessary, to ensure that the quality of the plated products is maintained.

- Monitor the plating baths for changes in pH, temperature, and concentration of the plating solution.

- Make adjustments to the plating parameters, such as the temperature of the plating bath or the current density, to maintain the desired quality of the plated products.

3. Troubleshooting Plating Problems

Plating Engineers are responsible for troubleshooting plating problems and finding solutions. They analyze the problem, and determine the cause, and then develop and implement a solution.

- Analyze plating problems, such as poor adhesion of the plating, or the presence of defects in the plated surface.

- Determine the cause of the problem, such as contamination of the plating bath or improper preparation of the substrate.

- Develop and implement a solution to the problem, such as changing the plating parameters or modifying the substrate preparation process.

4. Quality Control

Plating Engineers are responsible for ensuring that the quality of the plated products meets or exceeds customer specifications. They inspect the plated products, and perform tests to ensure that they meet the required standards.

- Inspect the plated products for defects, such as poor adhesion of the plating or the presence of surface defects.

- Perform tests on the plated products, such as thickness measurements or corrosion tests, to ensure that they meet the required standards.

Interview Tips

Here are some tips for preparing for an interview for a Plating Engineer position:

1. Research the company

Before you go to an interview, it is important to research the company. This will help you understand their business, their products, and their culture. You can find information about the company on their website, in their annual report, or in articles about the company in the news.

- Visit the company’s website to learn about their products, services, and culture.

- Read the company’s annual report to learn about their financial performance and strategic goals.

- Search for articles about the company in the news to learn about their recent developments and industry reputation.

2. Prepare for common interview questions

There are some common interview questions that you are likely to be asked in an interview for a Plating Engineer position. It is important to prepare for these questions so that you can answer them confidently and concisely.

- Tell me about your experience in the plating industry.

- What are your strengths and weaknesses as a Plating Engineer?

- Why are you interested in this position?

- What are your salary expectations?

3. Practice your answers

Once you have prepared for the common interview questions, it is important to practice your answers. This will help you feel more confident and prepared during the interview.

- Practice answering the common interview questions out loud.

- Record yourself answering the questions and then listen to the recording to identify areas for improvement.

- Ask a friend or family member to role-play the interview with you.

4. Dress appropriately

First impressions matter, so it is important to dress appropriately for your interview. For a Plating Engineer position, it is best to dress in business casual attire.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your clothes are clean and pressed.

- Wear comfortable shoes that you can walk in easily.

5. Be yourself

The most important thing to remember is to be yourself during the interview. The interviewer wants to get to know you and learn about your skills and experience. So be yourself, and let your personality shine through.

- Be honest about your skills and experience.

- Show the interviewer your passion for the plating industry.

- Be yourself and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plating Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!