Are you gearing up for an interview for a Plating Equipment Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Plating Equipment Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

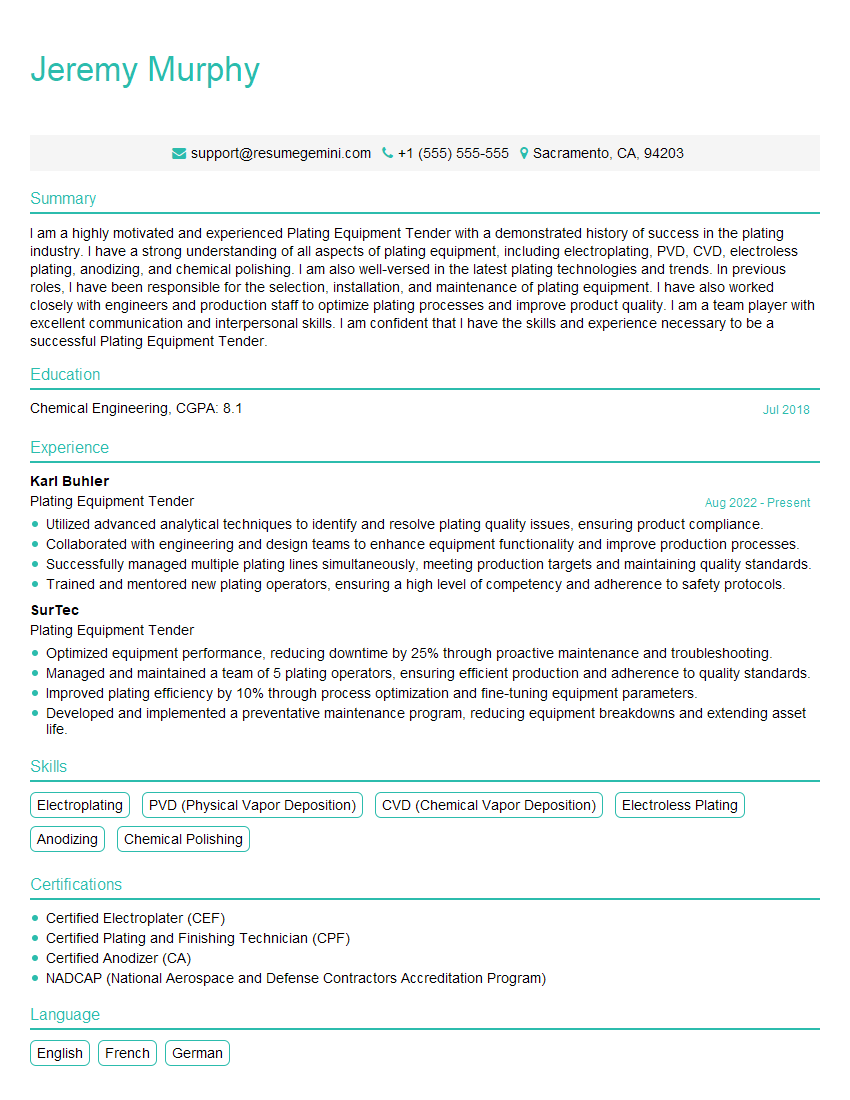

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plating Equipment Tender

1. What is the difference between barrel plating and rack plating?

- Barrel plating involves placing small parts in a rotating barrel, while rack plating involves hanging parts on a rack.

- Barrel plating is more efficient for small parts, while rack plating is better for larger or more delicate parts.

- Barrel plating provides more uniform coverage, while rack plating allows for more precise control of the plating thickness.

2. What type of plating equipment is best suited for a particular application?

Types of Plating Equipment

- Barrel plating

- Rack plating

- Vibratory plating

- Electroless plating

Factors to Consider

- Type of metal being plated

- Size and shape of the parts being plated

- Required plating thickness

- Desired finish

- Production volume

3. How do you maintain and troubleshoot plating equipment?

- Regularly cleaning and inspecting the equipment

- Lubricating moving parts

- Checking the electrical connections

- Monitoring the plating solution

- Troubleshooting common problems, such as poor adhesion, uneven plating, and pitting

4. What are the safety precautions to be taken when working with plating equipment?

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and a respirator

- Handle chemicals with care

- Be aware of the electrical hazards associated with plating equipment

- Follow all safety protocols and procedures

5. What are the latest trends in plating equipment?

- Automation

- Miniaturization

- Environmental sustainability

- Advanced materials

6. How do you stay up-to-date on the latest plating equipment technologies?

- Attend industry conferences and trade shows

- Read industry publications

- Network with other plating professionals

- Participate in online forums and discussion groups

7. What is your experience with different types of plating equipment?

- Type of plating equipment used

- Applications for which the equipment was used

- Key features and benefits of the equipment

- Any challenges encountered and how they were overcome

8. How do you ensure the quality of the plated products?

- Establishing and maintaining quality control procedures

- Inspecting incoming materials

- Monitoring the plating process

- Testing the finished products

- Taking corrective action when necessary

9. What are the key factors to consider when selecting a plating equipment supplier?

- Reputation and experience

- Product quality

- Price

- Delivery time

- Customer service

10. How do you handle customer complaints?

- Listen to the customer’s complaint and empathize with their concerns

- Investigate the situation to determine the root cause of the problem

- Develop and implement a solution

- Communicate the solution to the customer and keep them updated on its progress

- Follow up with the customer to ensure their satisfaction

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plating Equipment Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plating Equipment Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Plating Equipment Tender is responsible for the maintenance and operation of plating equipment in a manufacturing environment.

1. Equipment Maintenance

Inspects and maintains plating equipment, including tanks, pumps, filters, and control systems.

- Performs preventive maintenance to ensure the proper functioning of equipment.

- Troubleshoots and repairs equipment malfunctions.

2. Process Control

Monitors and controls plating processes to ensure the quality of plated products.

- Adjusts plating parameters, such as temperature, pH, and current density.

- Conducts tests to verify the quality of plated products.

3. Material Handling

Handles and stores plating materials, including chemicals, metals, and substrates.

- Prepares and loads materials into plating equipment.

- Unloads plated products and inspects them for defects.

4. Safety and Compliance

Follows safety protocols and regulations related to plating operations.

- Wears appropriate personal protective equipment.

- Maintains a clean and organized work area.

Interview Tips

Preparing for an interview for a Plating Equipment Tender position requires a combination of technical knowledge, industry-specific experience, and presentation skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and market position.

- Research the specific industry in which the company operates.

- Understand the latest trends and technologies in the plating industry.

2. Highlight Your Technical Expertise

Emphasize your knowledge and experience in plating equipment maintenance and operation.

- Provide specific examples of your troubleshooting and repair skills.

- Discuss your understanding of process control and quality assurance.

3. Showcase Your Safety Awareness

Demonstrate your commitment to safety and compliance in a manufacturing environment.

- Explain your knowledge of safety protocols and regulations related to plating operations.

- Provide examples of how you have ensured a safe and compliant work area.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare your responses accordingly.

- Describe your experience in maintaining and troubleshooting plating equipment.

- Explain your understanding of process control and quality assurance in a plating operation.

- How do you ensure compliance with safety protocols and regulations?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plating Equipment Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!