Are you gearing up for a career in Pleating Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pleating Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

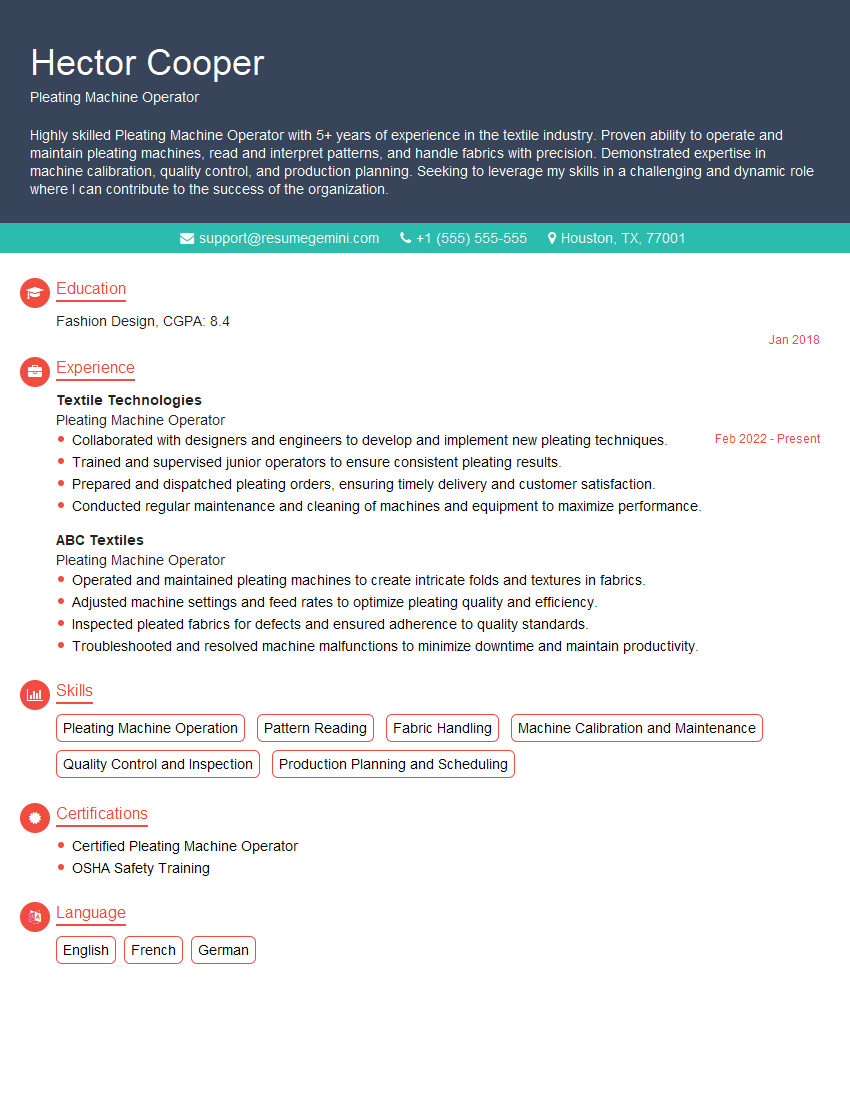

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pleating Machine Operator

1. Explain the working principle of a pleating machine?

- The machine uses a heated blade to cut and seal the fabric.

- The fabric is fed into the machine and pulled through a series of rollers.

- The blade cuts the fabric into pleats and the heat seals the edges.

- The pleats are then set in place by a cooling roller.

2. What are the different types of pleating machines?

Blade pleating machines

- Use a heated blade to cut and seal the fabric.

- Can produce a variety of pleat sizes and styles.

Roller pleating machines

- Use a series of rollers to create pleats.

- Can produce more uniform pleats than blade pleating machines.

Hydraulic pleating machines

- Use a hydraulic press to create pleats.

- Can produce very precise pleats.

3. How do you adjust the pleat size on a pleating machine?

- The pleat size is adjusted by changing the distance between the blade and the fabric.

- The distance can be adjusted by turning a knob or lever on the machine.

- The pleat size can also be adjusted by changing the speed of the machine.

4. How do you troubleshoot a pleating machine?

- If the pleats are not uniform, the blade may need to be sharpened or replaced.

- If the fabric is not feeding properly, the rollers may need to be adjusted.

- If the pleats are not setting properly, the cooling roller may need to be replaced.

5. What are the safety precautions that must be taken when operating a pleating machine?

- The machine should only be operated by trained personnel.

- The machine should be properly grounded.

- The blade should be guarded to prevent contact with the operator.

- The fabric should be fed into the machine evenly to prevent jamming.

6. What are the different types of fabrics that can be pleated?

- Most fabrics can be pleated, but some fabrics are more difficult to pleat than others.

- Lightweight fabrics, such as silk and chiffon, are easier to pleat than heavy fabrics, such as denim and canvas.

- Fabrics with a lot of stretch, such as knit fabrics, can be difficult to pleat without distorting the fabric.

7. What are the different applications for pleated fabrics?

- Pleated fabrics are used in a variety of applications, including clothing, home décor, and industrial products.

- In clothing, pleated fabrics are often used to create volume and texture.

- In home décor, pleated fabrics are often used to create curtains, blinds, and lampshades.

- In industrial products, pleated fabrics are often used to create filters and other components.

8. What are the trends in pleating?

- Some of the current trends in pleating include:

- The use of 3D printing to create pleats.

- The use of laser cutting to create intricate pleats.

- The use of new materials, such as metal and plastic, to create pleats.

- The use of pleats to create wearable art.

9. What is the future of pleating?

- The future of pleating is bright.

- New technologies are making it possible to create pleats that are more innovative and versatile than ever before.

- Pleats are becoming increasingly popular in a variety of applications, from clothing to home décor to industrial products.

- We can expect to see even more exciting and creative uses for pleats in the years to come.

10. How do you maintain a pleating machine?

- The machine should be cleaned and oiled regularly.

- The blade should be sharpened or replaced as needed.

- The rollers should be adjusted to ensure that the fabric is feeding properly.

- The cooling roller should be replaced as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pleating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pleating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pleating Machine Operator is responsible for operating and maintaining pleating machines to create pleats in fabrics. The primary duties of this role include:

1. Machine Operation:

Operating pleating machines to create precise pleats in fabrics.

2. Fabric Preparation:

Preparing fabrics for pleating by inspecting, measuring, and preparing the fabrics for the machine.

3. Machine Maintenance:

Inspecting, cleaning, and performing minor maintenance on pleating machines to ensure optimal performance.

4. Quality Control:

Monitoring the pleating process to ensure that the pleats meet the desired specifications and quality standards.

5. Production Monitoring:

Tracking production output, identifying and addressing any potential bottlenecks or delays.

6. Communication:

Communicating with supervisors, teammates, and customers regarding machine operation and fabric quality.

Interview Tips

To prepare for an interview as a Pleating Machine Operator, it is crucial to:

1. Research the Company and Role:

Gather information about the company’s history, products, and culture. Understand the specific responsibilities and requirements of the Pleating Machine Operator role.

2. Highlight Relevant Skills and Experience:

Emphasize your experience in operating pleating machines and handling various fabrics.

3. Practice Common Interview Questions:

Prepare for common interview questions, such as “Tell me about your experience in operating pleating machines” and “How do you ensure the quality of pleats?”

4. Demonstrate Enthusiasm for the Role:

Express your interest in the role and the pleating industry. Explain why you are eager to join the company and contribute to their success.

5. Ask Informed Questions:

Prepare questions to ask the interviewer about the company, the role, and the industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pleating Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.