Feeling lost in a sea of interview questions? Landed that dream interview for Plodding Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plodding Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

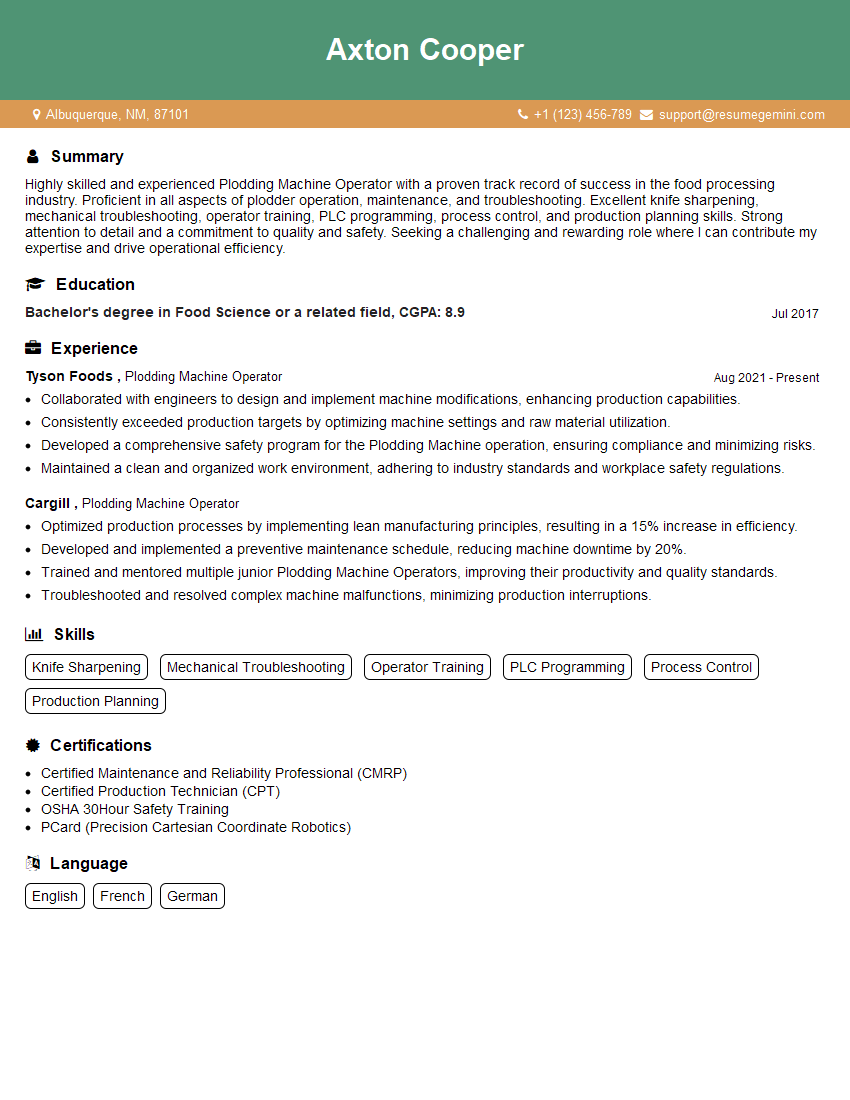

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plodding Machine Operator

1. What are the main components of a plodder machine?

- Hopper: The hopper holds the raw material, typically meat or vegetable matter, and feeds it into the machine.

- Auger: The auger is a screw-shaped conveyor that moves the material through the machine.

- Extruder: The extruder forces the material through a die, which shapes it into the desired form.

- Cutter: The cutter cuts the extruded material into uniform lengths.

- Conveyor: The conveyor moves the finished product away from the machine.

2. What are the different types of plodders?

Hydraulic plodders

- Hydraulic plodders use hydraulic pressure to force the material through the die.

- They are typically smaller and more portable than mechanical plodders.

- Hydraulic plodders are often used for small-scale production or for producing products with delicate textures.

Mechanical plodders

- Mechanical plodders use a mechanical drive to force the material through the die.

- They are typically larger and more powerful than hydraulic plodders.

- Mechanical plodders are often used for large-scale production or for producing products with tough textures.

3. What are the advantages of using a plodder machine?

- Plodders can produce a wide variety of products, including sausages, hot dogs, meatloaf, and pet food.

- Plodders can produce products with a consistent size and shape.

- Plodders can operate at high speeds, which can increase production efficiency.

- Plodders are relatively easy to operate and maintain.

4. What are the challenges of using a plodder machine?

- Plodders can be expensive to purchase and maintain.

- Plodders can be difficult to clean, which can lead to contamination of the product.

- Plodders can produce noise and vibration, which can be a nuisance to workers and neighbors.

- Plodders can be dangerous to operate, so it is important to follow all safety procedures.

5. What are the safety precautions that must be taken when operating a plodder machine?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Keep hands and feet away from moving parts.

- Do not operate the machine if it is damaged or if there are any loose parts.

- Follow all manufacturer’s instructions for safe operation.

- Be aware of the location of the emergency stop button and how to use it.

6. How do you maintain a plodder machine?

- Clean the machine thoroughly after each use.

- Inspect the machine regularly for wear and tear.

- Lubricate the machine according to the manufacturer’s instructions.

- Calibrate the machine regularly to ensure that it is producing products with the correct size and shape.

- Keep a record of all maintenance activities.

7. What is the difference between a plodder and an extruder?

- Plodders and extruders are both used to shape and form food products.

- Plodders use a piston to force the material through a die, while extruders use a screw conveyor to force the material through the die.

- Plodders are typically used for producing products with a more viscous consistency, such as sausages and hot dogs, while extruders are typically used for producing products with a more fluid consistency, such as sauces and pastes.

8. What is the role of a plodder machine operator?

- Operate the plodder machine to produce products according to specifications.

- Monitor the machine to ensure that it is operating properly.

- Make adjustments to the machine as needed.

- Clean and maintain the machine.

- Follow all safety procedures.

9. What are the skills and qualifications required to be a plodder machine operator?

- High school diploma or equivalent.

- Experience operating plodder machines.

- Knowledge of food safety and sanitation.

- Strong attention to detail.

- Ability to work independently and as part of a team.

10. What is the career outlook for plodder machine operators?

- The job outlook for plodder machine operators is expected to be good over the next few years.

- The demand for food products is expected to grow, which will lead to an increase in the demand for plodder machine operators.

- Plodder machine operators can find work in a variety of industries, including food processing, manufacturing, and retail.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plodding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plodding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plodding Machine Operator is accountable for operating, maintaining, and monitoring a plodding machine, which is used in the production of various food products, such as chocolate, margarine, and soap. The operator ensures that the machine runs smoothly and efficiently, producing high-quality products while adhering to safety regulations.

1. Machine Operation

Operate the plodding machine according to established procedures, ensuring optimal performance and product quality.

- Set up and adjust the machine for different production runs, ensuring proper feeding, processing, and discharge of materials.

- Monitor the machine’s operation, making necessary adjustments to maintain consistent product quality and prevent breakdowns.

2. Quality Control

Inspect the processed materials to ensure they meet quality standards and specifications. Conduct regular checks to identify and correct any deviations from the desired output.

- Sample and test processed materials to verify their texture, consistency, and other quality attributes.

- Identify and adjust process parameters such as temperature, pressure, and flow rate to optimize product quality.

3. Machine Maintenance

Perform routine maintenance and repairs on the plodding machine, ensuring its reliability and longevity.

- Lubricate, clean, and inspect the machine regularly to prevent breakdowns and ensure smooth operation.

- Troubleshoot and resolve minor mechanical issues, performing necessary adjustments or repairs to minimize downtime.

4. Safety and Compliance

Follow established safety protocols and maintain a clean and organized work area. Adhere to all applicable regulations and industry standards.

- Wear appropriate personal protective equipment (PPE) and follow safety guidelines to prevent accidents and injuries.

- Maintain a clean and organized work environment, minimizing the risk of contamination and ensuring compliance with food safety regulations.

Interview Tips

Preparing for an interview for a Plodding Machine Operator position requires thorough research about the role, the company, and the industry. Here are some essential tips to help candidates ace their interview:

1. Research the Role and Company

Familiarize yourself with the key responsibilities of a Plodding Machine Operator and the specific requirements of the position you are applying for. Visit the company’s website and social media pages to learn about their products, values, and work culture.

- Highlight your experience operating and maintaining similar machinery, emphasizing your technical skills and knowledge.

- Demonstrate your understanding of the production process and quality control procedures related to plodding machines.

2. Practice Your Answers

Prepare for common interview questions by practicing your responses. Consider potential questions about your experience, technical abilities, and safety awareness.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples of your accomplishments.

- Quantify your results whenever possible, using numbers or metrics to demonstrate the impact of your work.

3. Emphasize Safety and Quality

Safety and quality are paramount in this role. Highlight your commitment to following established protocols and maintaining a clean and organized work environment.

- Describe your experience in adhering to safety regulations and preventing accidents.

- Showcase your ability to identify and correct deviations from quality standards, ensuring the production of high-quality products.

4. Be Enthusiastic and Professional

During the interview, maintain a positive and professional demeanor. Show your enthusiasm for the role and your desire to contribute to the company’s success.

- Dress appropriately and arrive on time for the interview.

- Be respectful and courteous to the interviewer, actively listening to their questions and responding thoughtfully.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plodding Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plodding Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.