Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plow Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

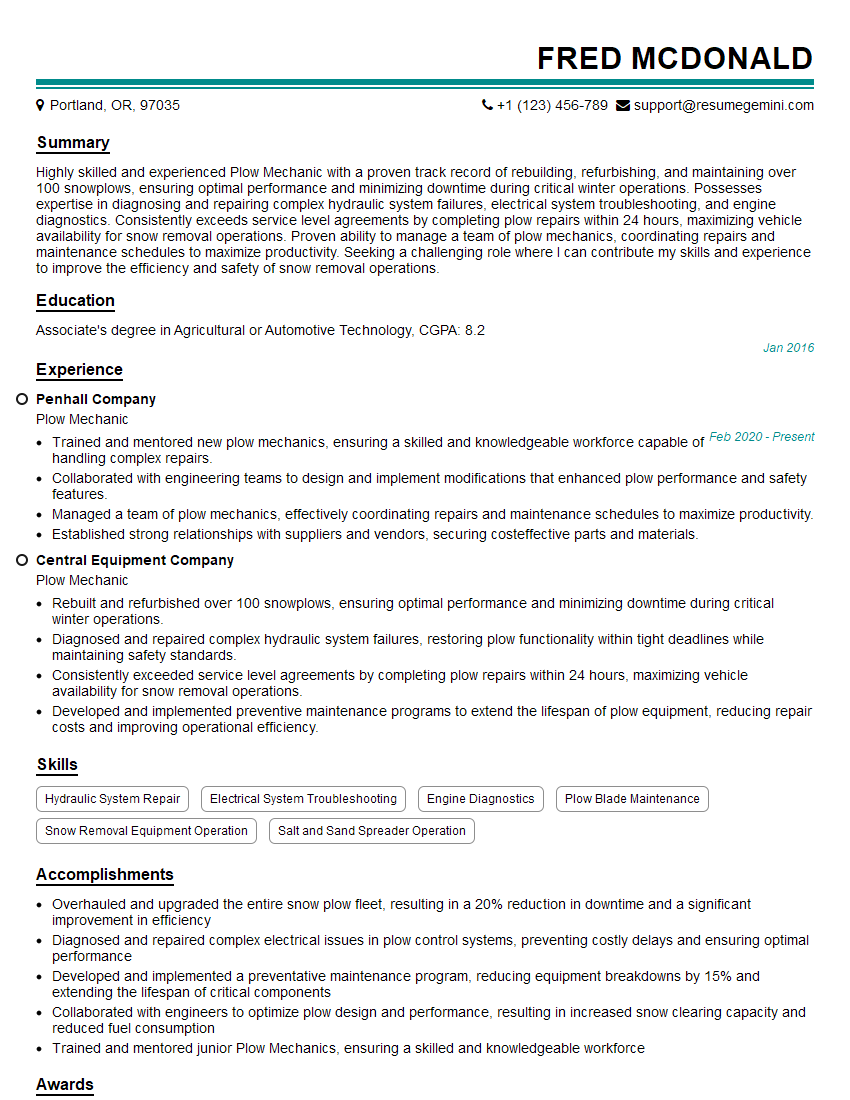

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plow Mechanic

1. What are the major components of a snowplow?

The major components of a snowplow include:

- Moldboard: The curved metal blade that pushes the snow.

- Trip edge: A spring-loaded edge that helps the plow ride over obstacles.

- Wings: Extendable sections that increase the width of the plow.

- Hydraulic system: Controls the movement of the moldboard and wings.

- Hitch: Connects the plow to the truck or vehicle.

2. How do you inspect and maintain a snowplow?

Pre-season Inspection

- Check the moldboard for cracks or damage.

- Inspect the trip edge for wear or damage.

- Test the hydraulic system for leaks or malfunctions.

- Lubricate all moving parts.

Regular Maintenance

- Inspect the plow daily for any damage or loose parts.

- Lubricate the moving parts regularly.

- Check the hydraulic fluid level and condition.

3. What are the common problems you encounter with snowplows, and how do you troubleshoot them?

Common problems with snowplows include:

- Moldboard damage: Inspect the moldboard for cracks or damage and repair or replace as necessary.

- Trip edge problems: Inspect the trip edge for wear or damage and replace if necessary.

- Hydraulic leaks: Check the hydraulic system for leaks and repair or replace any damaged components.

- Electrical problems: Check the electrical system for loose connections or damaged wires.

4. What safety precautions should be taken when operating a snowplow?

- Wear a seatbelt.

- Be aware of your surroundings.

- Do not plow too fast.

- Use caution when plowing near obstacles.

- Be aware of the weather conditions.

5. How do you ensure that a snowplow is properly calibrated?

To ensure proper calibration of a snowplow:

- Check the angle of the moldboard.

- Adjust the trip edge.

- Set the hydraulic pressure.

- Test the plow in different conditions.

6. What are the different types of snowplow blades, and when is each type most appropriate?

- Steel blades: Durable and suitable for heavy-duty plowing.

- Poly blades: Lightweight and flexible, ideal for light-duty plowing.

- Rubber blades: Gentle on surfaces and suitable for plowing delicate areas.

- Combination blades: Combine the benefits of different materials.

7. How do you handle difficult plowing conditions, such as icy or deep snow?

- Use a heavier blade for icy conditions.

- Apply chains or weights to the plow for added traction in deep snow.

- Plow slowly and carefully, avoiding sudden movements.

- Use a scraper or broom to remove ice and packed snow from the blade.

8. What is the importance of proper snowplow maintenance?

Proper snowplow maintenance is important for:

- Safety: Ensuring the plow is in good working order reduces the risk of accidents.

- Efficiency: A well-maintained plow will perform better and clear snow more effectively.

- Cost savings: Regular maintenance can extend the life of the plow and prevent costly repairs.

- Compliance: Some jurisdictions may have regulations requiring regular snowplow maintenance.

9. How do you stay up-to-date on the latest snowplow technology and best practices?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Consult with manufacturers and suppliers.

- Network with other snowplow operators.

10. How do you handle customer inquiries and complaints about snowplow services?

To handle customer inquiries and complaints effectively:

- Listen attentively to the customer’s concerns.

- Respond promptly and courteously.

- Investigate the issue thoroughly.

- Offer a solution or resolution that meets the customer’s needs.

- Follow up to ensure customer satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plow Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plow Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plow Mechanics are responsible for the maintenance and repair of snowplows, including the installation and removal of snowplow blades and other attachments. They also perform general maintenance on the vehicles, such as oil changes, tire rotations, and brake inspections. Some of the key job responsibilities of a Plow Mechanic include:

1. Inspecting and Maintaining Snowplows

Plow Mechanics are responsible for inspecting and maintaining snowplows to ensure that they are in good working order. This includes checking the plow’s blade, hydraulics, and electrical systems. They also lubricate and adjust the plow’s components as needed.

2. Installing and Removing Snowplow Blades

Plow Mechanics are responsible for installing and removing snowplow blades. This is a critical task, as the blade is the primary component of the plow and must be properly installed to ensure that the plow operates safely and efficiently.

3. Troubleshooting and Repairing Snowplows

Plow Mechanics are responsible for troubleshooting and repairing snowplows. This includes diagnosing the problem, making the necessary repairs, and testing the plow to ensure that it is functioning properly.

4. General Maintenance on Vehicles

In addition to working on snowplows, Plow Mechanics may also perform general maintenance on the vehicles that they are used on. This includes oil changes, tire rotations, and brake inspections.

Interview Tips

Preparing for an interview for a Plow Mechanic position is essential to making a good impression and increasing your chances of landing the job. Here are some tips:

1. Research the Company and the Position

Before the interview, it is important to research the company and the position. This will help you to understand the company’s culture and the specific requirements of the job. You can research the company’s website, read articles about the company, and talk to people who work there.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Experience

In the interview, you will be asked about your experience as a Plow Mechanic. Be prepared to talk about your skills and experience in detail. You should also be able to provide examples of your work.

4. Ask Questions

At the end of the interview, you should ask the interviewer questions about the position and the company. This will show that you are interested in the job and that you are taking the interview seriously.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plow Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plow Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.