Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plug Cutting Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plug Cutting Machine Operator so you can tailor your answers to impress potential employers.

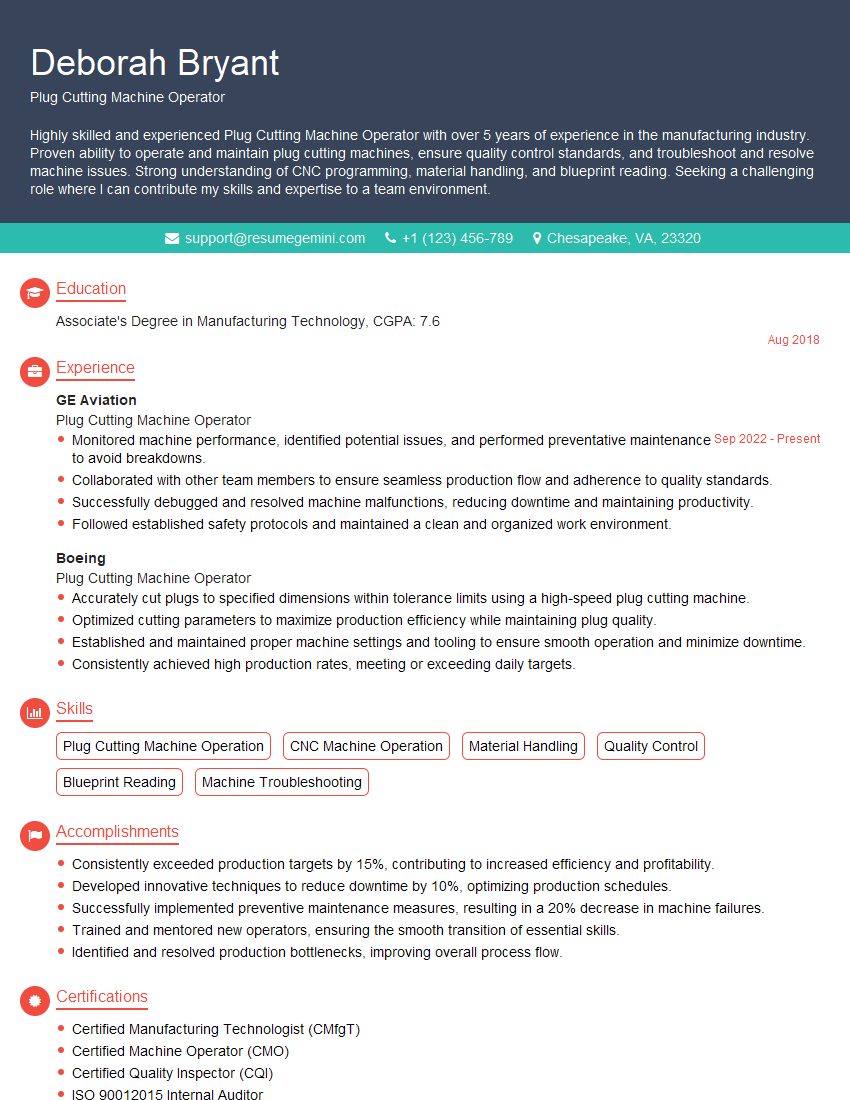

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plug Cutting Machine Operator

1. Describe the process of setting up a plug cutting machine?

- Inspect the machine for any damage or wear.

- Clean the work area and machine thoroughly.

- Install the appropriate cutting blade.

- Set the cutting depth and feed rate.

- Securely clamp the material to be cut.

- Calibrate the machine to ensure accurate cuts.

2. How do you maintain a plug cutting machine?

Daily Maintenance

- Clean the machine and remove any debris or sawdust.

- Lubricate all moving parts.

- Check the cutting blade for sharpness and replace if necessary.

Weekly Maintenance

- Inspect the machine for any loose or damaged parts.

- Check the electrical connections for any frayed wires or terminals.

- Calibrate the machine to ensure accurate cuts.

3. What are the safety precautions to follow when operating a plug cutting machine?

- Wear appropriate safety gear, including earplugs, safety glasses, and gloves.

- Keep the work area clean and free of clutter.

- Never reach into the cutting area while the machine is running.

- Use a push stick to feed material into the machine.

- Shut off the machine and unplug it before making any adjustments.

4. What are the different types of cutting blades used in a plug cutting machine?

- Standard blade: For general-purpose cutting.

- Carbide-tipped blade: For cutting harder materials.

- High-speed steel blade: For cutting non-ferrous metals.

- Diamond blade: For cutting glass, ceramic, and other hard materials.

5. How do you troubleshoot a plug cutting machine that is not cutting accurately?

- Check if the cutting blade is sharp and properly installed.

- Inspect the material being cut for any defects or inconsistencies.

- Adjust the cutting depth and feed rate to optimize cutting efficiency.

- Calibrate the machine to ensure accurate cuts.

- Check for any loose or damaged parts that may affect the machine’s performance.

6. What are the factors that determine the quality of a plug cut?

- Sharpness of the cutting blade – A sharp blade produces clean, precise cuts.

- Cutting depth – The cutting depth should be set according to the thickness of the material being cut.

- Feed rate – The feed rate controls the speed at which the material is fed into the machine.

- Material quality – The quality of the material being cut can affect the quality of the plug cut.

7. How do you handle common problems that may occur during plug cutting, such as burning or tearing?

- Reduce the cutting speed.

- Use a coolant or lubricant.

- Increase the cutting speed.

- Use a sharper blade.

- Reduce the cutting depth.

Burning

Tearing

8. Explain the importance of proper machine calibration in plug cutting.

- Ensures accurate and consistent cuts.

- Reduces scrap and waste.

- Improves machine efficiency and productivity.

- Helps maintain the machine’s accuracy and longevity.

9. How do you optimize the cutting process for different types of materials?

- Hard materials: Use a carbide-tipped blade and a slow feed rate.

- Soft materials: Use a standard blade and a faster feed rate.

- Thin materials: Use a shallow cutting depth and a low feed rate.

- Thick materials: Use a deep cutting depth and a high feed rate.

10. Discuss the importance of maintaining good housekeeping practices in the plug cutting area.

- Reduces the risk of accidents and injuries.

- Keeps the work area clean and organized, which improves efficiency.

- Helps prevent damage to the machine and materials.

- Creates a more positive and professional work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plug Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plug Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plug Cutting Machine Operators play a crucial role in the manufacturing industry, operating specialized machinery to produce precision-cut plugs. These plugs are often used in various applications such as electrical connectors, automotive components, and medical devices.

1. Machine Operation

An essential duty for Plug Cutting Machine Operators is to set up, operate, and maintain cutting machines effectively. This involves understanding the machine’s capabilities, selecting the appropriate cutting tools, and ensuring the machine is calibrated correctly.

- Follow established operating procedures and safety protocols.

- Monitor machine performance and make necessary adjustments to optimize production.

2. Quality Control

Plug Cutting Machine Operators are responsible for ensuring the quality of the plugs produced. They inspect the plugs for any defects, such as improper cuts, burrs, or dimensional inaccuracies. Operators also conduct regular maintenance and calibration checks to ensure the machine meets the required quality standards.

- Inspect plugs using gauges, calipers, and other measuring tools.

- Identify and correct any deviations from the specified tolerances.

3. Material Handling

Loading and unloading the cutting machine with raw materials and finished plugs is a significant part of the job. Operators must ensure that the materials are handled correctly to prevent damage and maintain cleanliness.

- Load and unload materials using appropriate handling equipment.

- Maintain a clean and organized work area to prevent accidents.

4. Troubleshooting and Maintenance

Plug Cutting Machine Operators must be able to troubleshoot and perform basic maintenance on the equipment they operate. They should be able to identify common problems, such as electrical malfunctions or mechanical issues, and take appropriate action to resolve them.

- Identify and diagnose potential problems with the machine.

- Perform routine maintenance tasks to keep the machine in optimal condition.

Interview Tips

Preparing thoroughly for a Plug Cutting Machine Operator interview is crucial to showcase your skills and increase your chances of success.

1. Research the Company and Industry

Familiarize yourself with the company’s website, mission, and products. Also, gain insights into the industry and market trends to demonstrate your interest and knowledge.

2. Practice Common Interview Questions

Anticipate common interview questions related to your experience, skills, and qualifications. Prepare thoughtful answers and practice delivering them confidently.

- Tell me about your experience operating plug cutting machines.

- How do you ensure the quality of the plugs produced?

- Give an example of a time you solved a problem with the cutting machine.

3. Highlight Your Technical Skills

Emphasize your technical skills, such as your proficiency in operating various types of plug cutting machines, understanding of cutting tools, and ability to troubleshoot and perform basic maintenance.

4. Display Your Safety Awareness

Safety is paramount in operating machinery. Highlight your knowledge of safety protocols and your commitment to maintaining a safe work environment.

5. Demonstrate Your Attention to Detail

Quality control is essential in this role. Showcase your attention to detail and your ability to detect and correct any deviations from the specified tolerances.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Plug Cutting Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.