Feeling lost in a sea of interview questions? Landed that dream interview for Ply Cutter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ply Cutter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

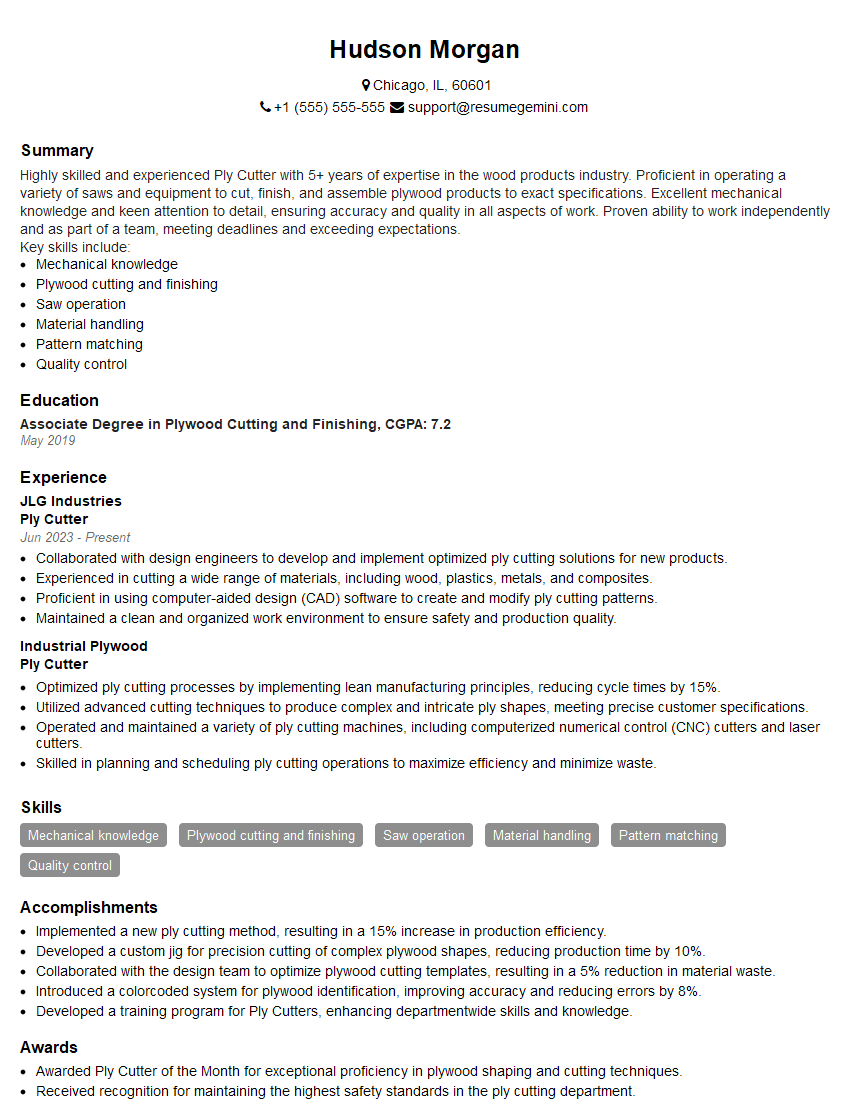

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ply Cutter

1. What is the purpose of a ply cutter?

A ply cutter is a machine or tool used to cut multiple layers of material, such as wood, plastic, or fabric, into desired shapes and sizes.

2. What are the different types of ply cutters?

CNC Ply Cutters:

- Controlled by computer numerical control (CNC) technology, providing high precision and accuracy.

- Capable of intricate cuts and complex shapes.

Manual Ply Cutters:

- Operated manually, requiring skilled operators.

- Less precise than CNC cutters, but offer flexibility and lower cost.

3. What are the important factors to consider when selecting a ply cutter?

- Type and thickness of material to be cut.

- Desired precision and accuracy.

- Production volume and speed requirements.

- Cost and maintenance considerations.

4. How do you ensure the safety and accuracy of a ply cutter?

- Properly calibrate and maintain the equipment.

- Wear appropriate safety gear, such as gloves and eye protection.

- Secure the material firmly to the cutter bed.

- Ensure accurate measurements and programming for CNC cutters.

5. What is kerf and how does it affect ply cutting?

Kerf refers to the width of the cut made by the ply cutter blade. It affects the accuracy and efficiency of the cutting process. A wider kerf can result in reduced precision and increased material waste.

6. How do you minimize waste when using a ply cutter?

- Optimize cutting patterns to minimize scrap.

- Nest cuts closely together to avoid gaps.

- Consider using thinner blades to reduce kerf.

- Recycle scrap material whenever possible.

7. What are some common problems that can occur when using a ply cutter?

- Blade dulling or breakage.

- Inaccurate cuts due to misalignment or calibration issues.

- Material warping or splitting during the cutting process.

- Safety hazards, such as flying debris or loose blades.

8. How do you troubleshoot a ply cutter that is not functioning properly?

- Inspect the blade for damage or dullness.

- Check for any loose or misaligned components.

- Re-calibrate the equipment if necessary.

- Ensure that the material is properly secured.

- Refer to the manufacturer’s guidelines for maintenance and troubleshooting.

9. What are the safety regulations and standards that apply to ply cutter operations?

- OSHA regulations regarding machine safety and guarding.

- ANSI standards for woodworking machinery.

- Company-specific safety protocols and best practices.

10. How do you stay up-to-date with the latest ply cutting technologies and techniques?

- Attend industry conferences and workshops.

- Read trade publications and technical articles.

- Seek training from manufacturers or experienced professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ply Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ply Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ply Cutters play a crucial role in the manufacturing process, ensuring the efficient and accurate cutting of plywood or similar materials.

1. Plywood Cutting

Using high-powered saws, Ply Cutters precisely cut large sheets of plywood into smaller pieces based on specified dimensions and patterns.

2. Machine Operation and Maintenance

Ply Cutters expertly operate and maintain automated or semi-automated cutting machinery, ensuring consistent and high-quality cuts.

3. Material Handling

They skillfully lift and manipulate heavy plywood sheets, adhering to safety regulations and ergonomic principles.

4. Quality Control

Ply Cutters inspect cut pieces for accuracy, ensuring they meet established quality standards and customer specifications.

Interview Tips

Preparing for a Ply Cutter interview is essential to showcase your skills and experience effectively. Here are some crucial tips:

1. Research the Company and Industry

Thoroughly research the company and the plywood industry to gain insights into their culture, products, and market dynamics. This knowledge will help you align your answers with their specific needs.

2. Highlight Relevant Skills and Experience

Emphasize your skills in plywood cutting, machinery operation, and quality control. Quantify your accomplishments and provide specific examples to demonstrate your capabilities.

3. Prepare for Technical Questions

Anticipate questions related to saw operation, cutting techniques, and equipment maintenance. Practice answering these questions clearly and concisely, demonstrating your technical proficiency.

4. Show Safety Awareness

Highlight your understanding of safety protocols and regulations in the workplace. Explain how you ensure the safety of yourself and others while working with heavy machinery.

5. Prepare Example Questions

Prepare thoughtful questions to ask the interviewer. This shows your interest in the company, the position, and your potential for growth.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ply Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!