Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plywood Matcher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plywood Matcher so you can tailor your answers to impress potential employers.

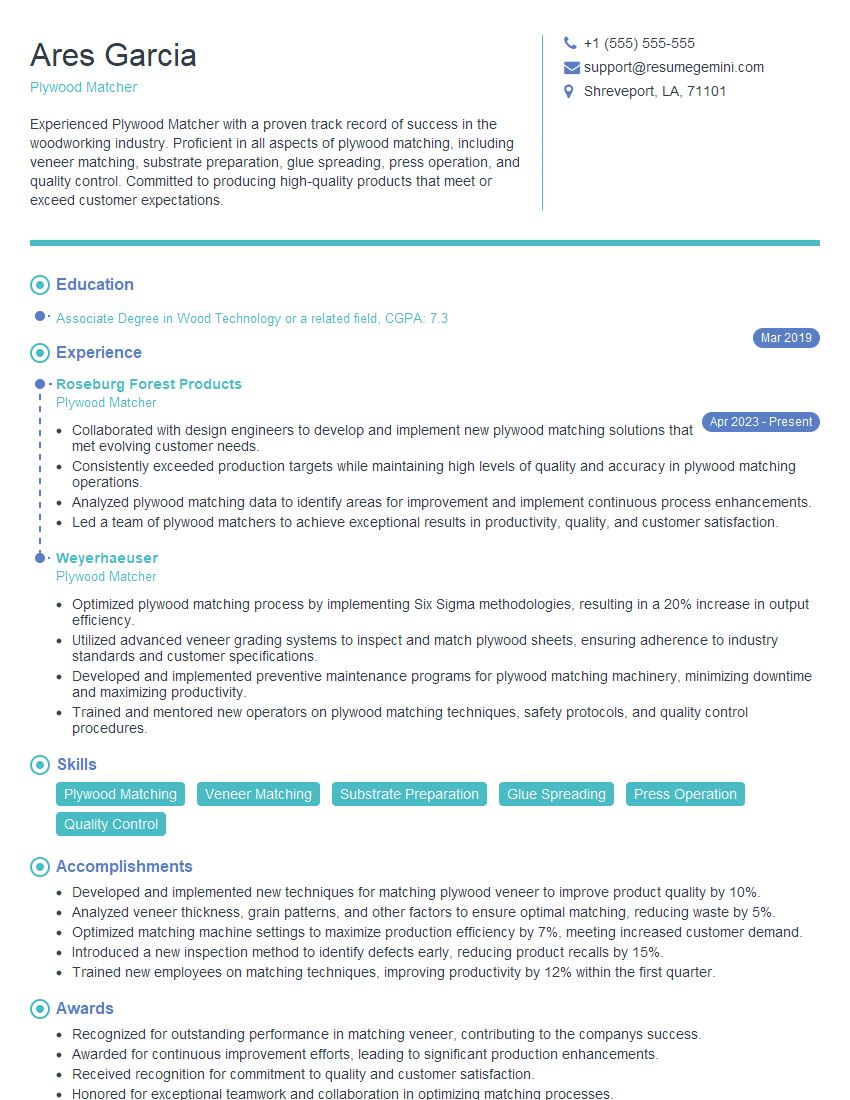

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plywood Matcher

1. How do you ensure that the veneers are matched properly before gluing?

To ensure proper veneer matching, I employ the following techniques:

- Visual Inspection: I carefully examine the veneers under various lighting conditions to identify and mark any similarities or patterns.

- Taping: I use transparent tape to temporarily adhere the veneers together and inspect them for grain alignment and color consistency.

- Spreadout: I spread out the veneers on a large, flat surface to visualize the overall pattern and identify any potential mismatches.

- Color Matching: I use color swatches or digital tools to compare the shades of the veneers and ensure they complement each other aesthetically.

2. What is the significance of grain direction in plywood matching?

Matching Grain Direction for Strength

- Matching the grain direction of the veneers in each layer ensures the plywood’s strength and stability.

- When the grains are aligned, the wood fibers form a continuous path, providing greater resistance to bending and warping.

Matching Grain Direction for Aesthetics

- Matching the grain direction also enhances the visual appeal of the plywood.

- Consistent grain patterns create a pleasing and seamless appearance, making the plywood suitable for decorative applications.

3. How do you deal with defects or blemishes in veneers during the matching process?

When encountering defects or blemishes in veneers, I take the following steps:

- Identify and Mark: I carefully inspect the veneers and mark any noticeable defects or blemishes.

- Repair or Replace: If possible, I will attempt to repair minor defects using wood filler or patching techniques.

- Strategic Placement: I strategically position veneers with defects or blemishes in less visible areas, such as the back or interior surfaces.

- Avoidance: In cases of significant defects or blemishes, I avoid using those veneers in the final match.

4. What are the different gluing techniques used in plywood matching?

In plywood matching, various gluing techniques are employed:

- Spread Glue: This method involves applying a uniform layer of adhesive to both surfaces of the veneers and then pressing them together.

- Roll Glue: A specialized machine is used to apply a thin, even layer of adhesive to the veneers before pressing.

- Spray Glue: Adhesive is sprayed onto the veneer surfaces and allowed to become tacky before pressing.

- Hot Melting Glue: This type of adhesive is heated until it becomes liquid and then applied to the veneers, which are immediately pressed together.

5. How do you ensure the proper alignment of veneers during pressing?

To ensure correct veneer alignment during pressing, I adhere to the following guidelines:

- Alignment Marks: I mark registration points on the veneers and use these as reference guides when aligning them.

- Positioning Guides: I utilize specialized guides or jigs to precisely position and hold the veneers in place during pressing.

- Hand Clamping: I use hand clamps or straps to apply even pressure and keep the veneers aligned throughout the pressing process.

6. What is the importance of using correct pressure during pressing?

Applying the correct pressure during pressing is crucial for several reasons:

- Adhesive Bonding: Proper pressure ensures that the adhesive forms a strong bond between the veneers, resulting in a durable and cohesive plywood panel.

- Veneer Alignment: Accurate pressure helps maintain the precise alignment of the veneers throughout the panel.

- Surface Flatness: Applying even pressure prevents warping or buckling, ensuring a flat and uniform plywood surface.

7. How do you inspect the finished plywood for quality assurance?

Once the plywood pressing is complete, I perform a thorough inspection to ensure quality:

- Visual Examination: I visually inspect the plywood for any defects, such as mismatched veneers, uneven surfaces, or glue residue.

- Dimensional Measurement: I verify the dimensions of the plywood against the specified specifications to ensure accuracy.

- Glue Joint Strength: I conduct destructive or non-destructive tests to assess the strength of the glue joints.

- Moisture Content: I measure the moisture content of the plywood to ensure it meets the desired level for optimal performance.

8. What are the different factors that affect the production efficiency of plywood matching?

Several factors can impact the production efficiency of plywood matching:

- Veneer Quality: The quality and consistency of the veneers used have a significant impact on the efficiency of matching.

- Equipment Performance: The accuracy and reliability of the matching equipment, such as spreaders and presses, are crucial for efficient production.

- Operator Skill: The skill and experience of the plywood matcher play a vital role in optimizing production efficiency.

- Process Optimization: Streamlining the matching process, including material handling and inventory management, can improve efficiency.

9. What are the latest advancements in plywood matching technology?

The plywood matching industry has witnessed the following advancements in technology:

- Automated Matching Systems: These systems utilize computer-aided design (CAD) software and robotic arms to automate the matching process, reducing labor requirements and improving efficiency.

- Laser Scanning Technology: Laser scanners are used to create precise digital representations of veneers, enabling better grain matching and defect detection.

- Advanced VeneerGrading Techniques: AI-powered grading systems help identify and classify veneers based on grain patterns and quality, facilitating more efficient matching.

10. How do you stay updated with the latest industry trends and advancements in plywood matching?

To stay current with industry trends and advancements in plywood matching, I:

- Attend Trade Shows and Conferences: I regularly participate in industry events to connect with experts and learn about new technologies and practices.

- Read Industry Publications: I subscribe to trade magazines and journals to access the latest technical articles and case studies.

- Network with Peers: I engage with other plywood matchers and industry professionals through online forums and professional organizations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plywood Matcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plywood Matcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plywood Matcher is responsible for matching and joining pieces of veneer to create plywood. This involves inspecting the veneer for defects, cutting the veneer to the correct size, and gluing and pressing the pieces together. The Plywood Matcher also ensures that the plywood meets the required specifications for thickness, strength, and appearance.

1. Inspects veneer for defects

The Plywood Matcher visually inspects each piece of veneer for defects such as knots, splits, and holes. Any defective pieces are rejected and replaced with good pieces.

2. Cuts veneer to the correct size

The Plywood Matcher uses a saw or a knife to cut the veneer to the correct size. The pieces must be cut accurately so that they fit together properly.

3. Glues and presses the pieces together

The Plywood Matcher applies glue to the edges of the veneer pieces and then presses them together. The pieces are pressed under high pressure to ensure that they bond securely.

4. Ensures that the plywood meets the required specifications

The Plywood Matcher checks the finished plywood to ensure that it meets the required specifications for thickness, strength, and appearance. Any plywood that does not meet the specifications is rejected.

Interview Tips

Preparing for an interview can be daunting, but there are some things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Plywood Matcher position:

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the specific requirements of the position.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience and qualifications. Be prepared to talk about your work history, your skills, and your accomplishments. You should also be able to explain how your experience and qualifications make you a good fit for the Plywood Matcher position.

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic and positive about the position. Be sure to convey your excitement about the opportunity to work for the company and your passion for the Plywood Matcher trade.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Plywood Matcher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.