Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plywood Scarfer Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

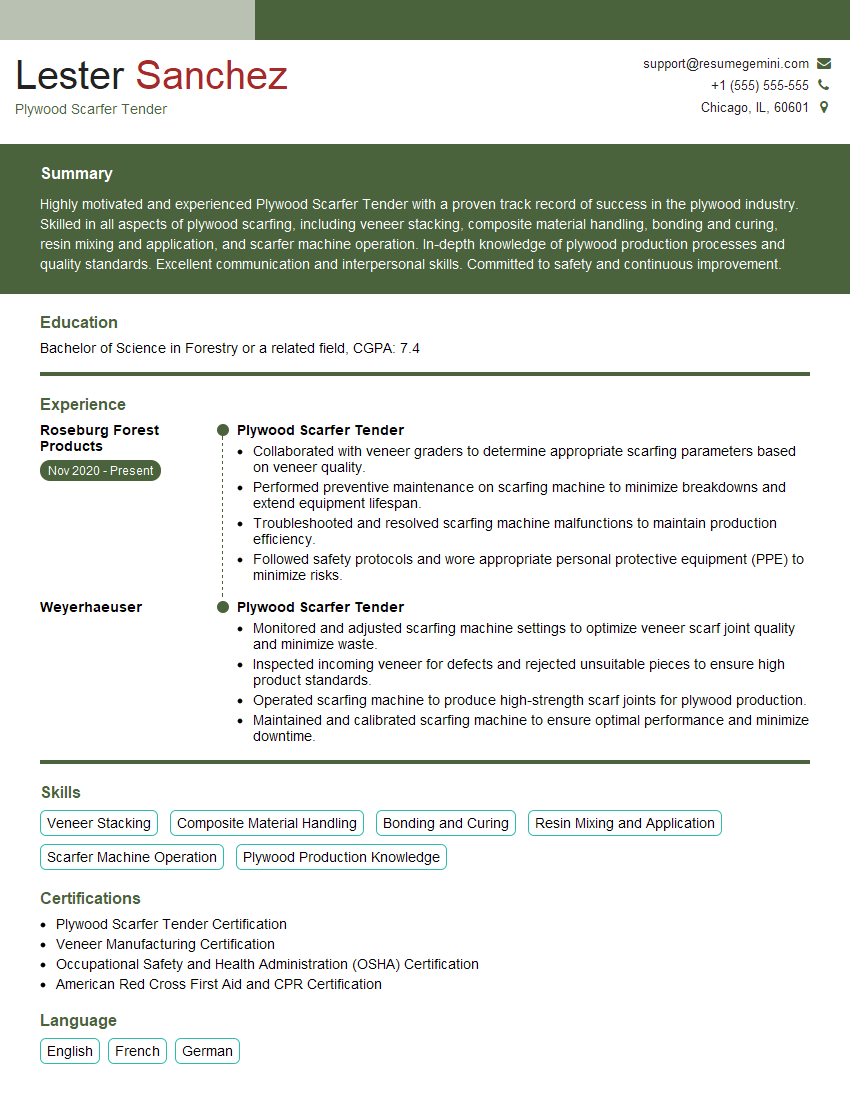

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plywood Scarfer Tender

1. Explain about the working principle of a Plywood Scarfer?

A Plywood Scarfer is a machine used to join two or more pieces of veneer together to form a single, continuous sheet. It works on the principle of scarf jointing, where the edges of the veneers are tapered and then glued together to create a strong and durable bond.

- The machine consists of a frame, a table, a cutter and a pressure system.

- The veneers are placed on the table and aligned with each other.

- The cutter is then lowered onto the veneers and makes a tapered cut along the edges.

- The veneers are then glued together and the pressure system is applied to hold them in place while the glue dries.

2. Describe the different types of scarf joints used in Plywood Scarfing?

Types of Scarf Joints

- Single Scarf Joint: This is the simplest type of scarf joint, where the edges of the veneers are tapered at a single angle.

- Double Scarf Joint: This joint is stronger than a single scarf joint, as the edges of the veneers are tapered at two different angles.

- Finger Joint: This joint is used to join veneers that are not straight or have irregular edges.

Factors affecting the choice of scarf joint

- Strength requirement

- Type of veneer being used

- Thickness of the veneer

3. What are the key parameters to consider when setting up a Plywood Scarfer?

The key parameters to consider when setting up a Plywood Scarfer are:

- Veneer Thickness: The thickness of the veneer will determine the depth of the cut made by the cutter.

- Scarf Angle: The angle of the scarf joint will affect the strength of the joint.

- Glue Spread: The amount of glue applied to the veneers will affect the strength of the bond.

- Pressure: The amount of pressure applied to the veneers will help to hold them in place while the glue dries.

- Cutter Speed: The speed of the cutter will affect the quality of the cut.

4. How do you ensure the quality of the scarf joint?

The quality of the scarf joint can be ensured by:

- Using sharp cutters

- Setting the correct scarf angle

- Applying the correct amount of glue

- Applying the correct amount of pressure

- Inspecting the joint after it has been made

5. What are the common problems that can occur during Plywood Scarfing?

The common problems that can occur during Plywood Scarfing are:

- Chipping or tearing of the veneer: This can be caused by using dull cutters or setting the scarf angle too steep.

- Weak joint: This can be caused by not applying the correct amount of glue or pressure.

- Misalignment of the veneers: This can be caused by not properly aligning the veneers before cutting.

- Glue squeeze-out: This can be caused by applying too much glue.

6. How do you maintain a Plywood Scarfer?

A Plywood Scarfer should be maintained by:

- Cleaning the machine regularly

- Sharpening the cutters regularly

- Checking the glue system regularly

- Calibrating the machine regularly

7. What are the safety precautions to be taken when operating a Plywood Scarfer?

The safety precautions to be taken when operating a Plywood Scarfer are:

- Wear appropriate safety gear, including gloves and safety glasses.

- Make sure the machine is properly grounded.

- Keep the work area clean and free of debris.

- Never operate the machine with dull cutters.

- Never reach into the machine while it is running.

8. How do you troubleshoot common problems that occur during Plywood Scarfing?

The common problems that occur during Plywood Scarfing can be troubleshooted by:

- Chipping or tearing of the veneer: Use sharp cutters and set the correct scarf angle.

- Weak joint: Apply the correct amount of glue and pressure.

- Misalignment of the veneers: Properly align the veneers before cutting.

- Glue squeeze-out: Apply the correct amount of glue.

9. What are the latest advancements in Plywood Scarfing technology?

The latest advancements in Plywood Scarfing technology include:

- Computer-controlled scarfing machines: These machines are more accurate and efficient than manual scarfing machines.

- Laser scarfing machines: These machines use lasers to cut the scarf joints, which results in a higher quality joint.

- Ultrasonic scarfing machines: These machines use ultrasonic waves to cut the scarf joints, which results in a stronger and more durable joint.

10. How do you stay up-to-date with the latest Plywood Scarfing technology?

I stay up-to-date with the latest Plywood Scarfing technology by:

- Reading trade publications

- Attending industry conferences

- Visiting the websites of Plywood Scarfing machine manufacturers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plywood Scarfer Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plywood Scarfer Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Plywood Scarfer Tender is responsible for operating and maintaining the scarfing machine, which cuts and bevels the edges of plywood panels. The key job responsibilities include:

1. Machine Operation and Maintenance

Operate the scarfing machine according to established procedures to cut and bevel plywood panels.

- Monitor the machine during operation and make necessary adjustments to ensure smooth functioning.

- Perform routine maintenance and cleaning of the machine to maintain optimal performance.

2. Material Handling

Load and unload plywood panels from the machine.

- Inspect panels for defects and reject any defective pieces.

- Stack and arrange panels according to specifications.

3. Quality Control

Inspect scarf joints for accuracy and adherence to specifications.

- Identify and report any defects or irregularities to the supervisor.

- Follow quality control procedures to ensure the production of high-quality plywood.

4. Workplace Safety

Maintain a safe work environment by following established safety protocols.

- Wear appropriate personal protective equipment (PPE).

- Operate machinery safely and avoid unsafe practices.

- Report any potential hazards or accidents to the supervisor.

Interview Tips

To ace the interview for the Plywood Scarfer Tender position, follow these tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and culture.

- Research the specific responsibilities of the Plywood Scarfer Tender role.

- Identify the key skills and qualifications required for the position.

- Prepare examples and anecdotes that demonstrate your alignment with the company and the role.

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare insightful answers.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Provide specific examples that showcase your skills and experience.

- Highlight your ability to operate and maintain machinery, handle materials, and ensure quality.

3. Demonstrate Your Safety Awareness

Emphasize your commitment to workplace safety.

- Describe your understanding of relevant safety protocols and regulations.

- Share examples of your proactive approach to preventing accidents.

- Explain how you would respond to potential hazards or emergencies.

4. Be Enthusiastic and Confident

Convey your interest in the position and the company.

- Show your enthusiasm for the role and how it aligns with your career goals.

- Maintain a positive and confident demeanor throughout the interview.

- Ask thoughtful questions that demonstrate your engagement and interest.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plywood Scarfer Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!