Feeling lost in a sea of interview questions? Landed that dream interview for Pneudraulic Systems Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pneudraulic Systems Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

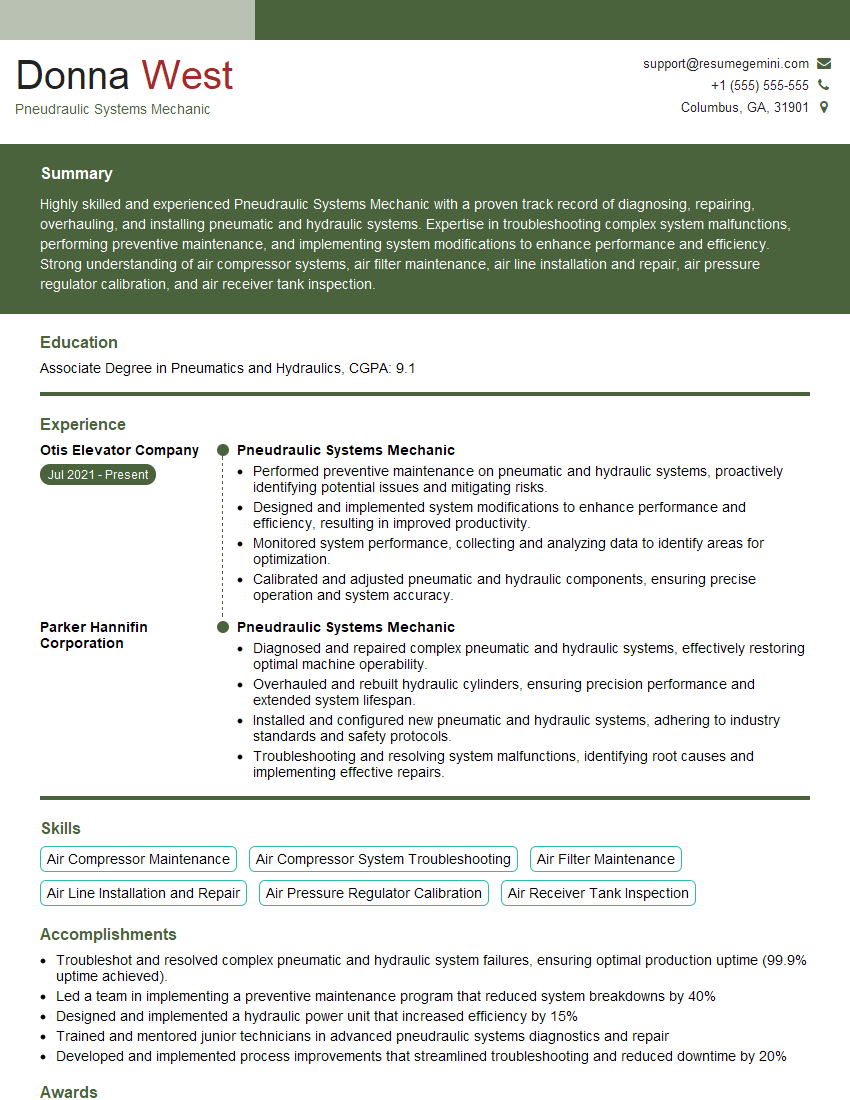

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pneudraulic Systems Mechanic

1. Explain the working principle of a pneumatic system?

A pneumatic system uses compressed air to power pneumatic devices such as actuators, motors, and tools. The compressed air is generated by an air compressor and stored in a receiver tank. When a pneumatic device is activated, the compressed air is released from the receiver tank and flows through a network of pipes and hoses to the device. The compressed air provides the force to operate the device.

2. What are the different types of pneumatic actuators?

Linear actuators

- Diaphragm actuators

- Piston actuators

- Rack and pinion actuators

Rotary actuators

- Vane actuators

- Gear motors

3. What are the advantages and disadvantages of using pneumatic systems?

Advantages:

- Pneumatic systems are clean and efficient.

- Pneumatic systems are relatively inexpensive to install and maintain.

- Pneumatic systems are safe to use in hazardous environments.

- Pneumatic systems provide a high power-to-weight ratio.

Disadvantages:

- Pneumatic systems can be noisy.

- Pneumatic systems can be affected by changes in temperature and pressure.

- Pneumatic systems require a source of compressed air.

4. What are the different types of hydraulic fluids?

- Mineral oils

- Synthetic oils

- Water-based fluids

- Fire-resistant fluids

5. What are the advantages and disadvantages of using hydraulic systems?

Advantages:

- Hydraulic systems are very efficient.

- Hydraulic systems are capable of providing high power.

- Hydraulic systems are relatively easy to control.

- Hydraulic systems are relatively quiet.

Disadvantages:

- Hydraulic systems can be expensive to install and maintain.

- Hydraulic systems can be dangerous if not properly maintained.

- Hydraulic systems can be affected by changes in temperature.

6. What are the different types of hydraulic pumps?

- Gear pumps

- Vane pumps

- Piston pumps

7. What are the different types of hydraulic valves?

- Directional control valves

- Pressure control valves

- Flow control valves

8. What are the different types of hydraulic actuators?

- Linear actuators

- Rotary actuators

- Hydraulic motors

9. What are the different types of hydraulic systems?

- Open-center systems

- Closed-center systems

- Load-sensing systems

10. What are the different types of hydraulic troubleshooting?

- Pressure troubleshooting

- Flow troubleshooting

- Temperature troubleshooting

- Electrical troubleshooting

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pneudraulic Systems Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pneudraulic Systems Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pneudraulic Systems Mechanics work primarily in the industrial sector and are responsible for the installation, maintenance, and repair of pneumatic and hydraulic systems in a variety of applications, including manufacturing, automotive, and construction.

1. Installation

The mechanic must have a thorough understanding of blueprints, schematic diagrams, and technical specifications to ensure the proper installation of the systems.

- Install, assemble, and connect sensors, actuators, tubing, and other components of pneumatic and hydraulic systems.

- Ensure that all components are properly aligned, sealed, and secured.

2. Maintenance

They must perform regular inspections, diagnostics, and testing to identify any potential issues and ensure the smooth operation of the systems.

- Conduct routine inspections and maintenance checks to ensure the proper functioning of the systems.

- Replace worn or damaged components, such as seals, filters, and valves.

3. Repair

When a system malfunctions, the mechanic must quickly diagnose the problem and implement the appropriate repair.

- Troubleshoot and diagnose malfunctions in pneumatic and hydraulic systems.

- Repair or replace faulty components, such as cylinders, pumps, and valves.

4. Troubleshooting and Diagnostics

In the event of a system malfunction, mechanics must be able to accurately diagnose the source of the issue and determine the appropriate course of action.

- Perform troubleshooting and diagnostic tests to identify the root cause of system failures

- Use specialized tools and equipment to pinpoint and resolve system malfunctions

Interview Tips

Beginning your interview preparation as early as possible provides you with ample time to gather your thoughts, effectively prepare responses, and develop thoughtful questions. Here are some interview preparation tips and hacks that can help you showcase your skills and qualities to the interviewer and increase your chances of success:

1. Research the company and the position

Familiarizing yourself with the company’s background, industry, mission, values, products or services, and current events demonstrates your eagerness and commitment to the position and the company.

- Visit the company website and review its About Us page, newsroom, and social media profiles.

- Search for recent articles or press releases about the company’s activities.

- Utilize professional networking platforms like LinkedIn to connect with employees or alumni of the organization.

2. Practice common interview questions

Anticipating and preparing for the types of questions you may encounter during the interview gives you the opportunity to thoughtfully craft your responses, highlighting your qualifications and experiences.

- Research common interview questions and prepare your answers using the STAR method: Situation, Task, Action, Result.

- Practice answering questions out loud to gain confidence and fluency in your delivery.

- Consider asking a friend, family member, or career counselor to conduct a mock interview with you.

3. Highlight your relevant skills and experience

Tailor your resume and cover letter to the specific requirements of the Pneudraulic Systems Mechanic position. Emphasize your technical expertise, hands-on experience, and problem-solving abilities.

- Review the job description thoroughly and identify the essential skills and qualifications.

- Quantify your accomplishments whenever possible using specific metrics or data points.

- Prepare examples of projects or situations where you successfully applied your skills to solve problems or achieve results.

4. Showcase your passion for the field

Expressing your enthusiasm for the field of pneumatics and hydraulics can set you apart from other candidates. Highlight your interest in the industry and your desire to learn and grow.

- Share any relevant hobbies, personal projects, or certifications that demonstrate your passion for the field.

- Discuss your understanding of current trends and advancements in the industry.

- Ask insightful questions about the company’s products or services and how they are applied in different industries.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pneudraulic Systems Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!