Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pneumatic Jack Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

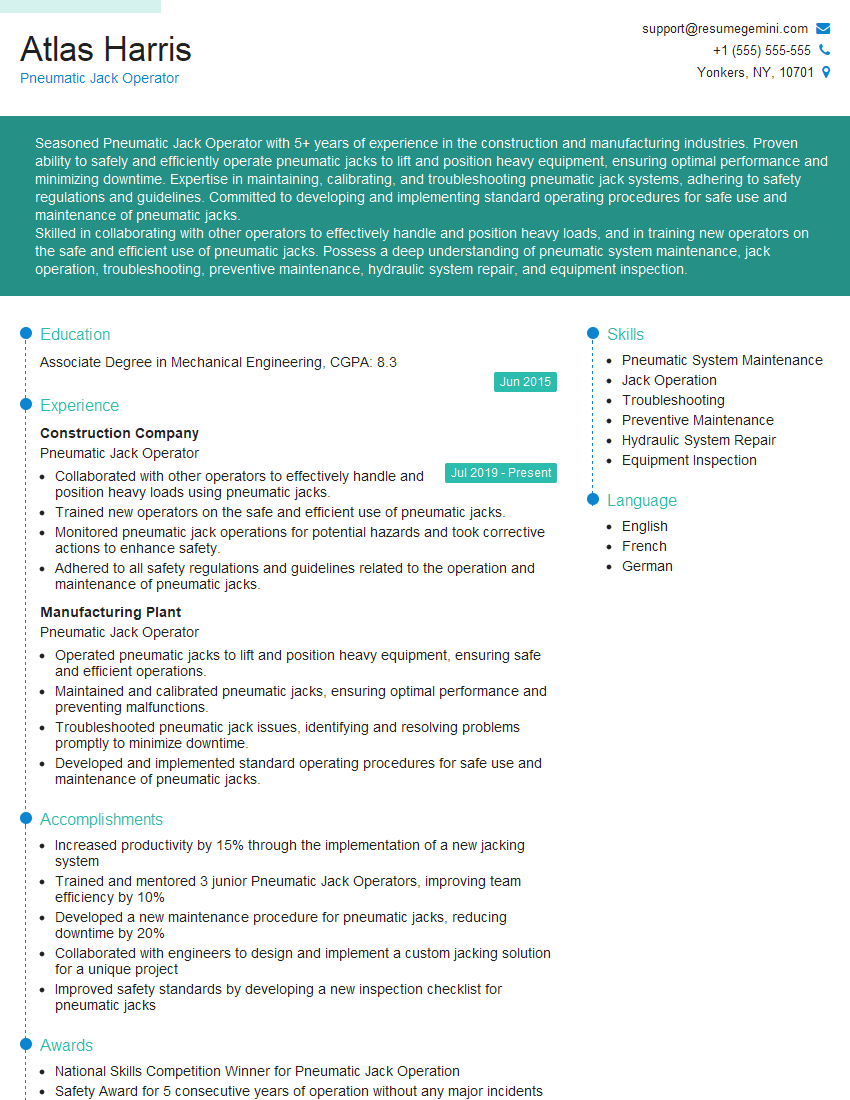

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pneumatic Jack Operator

1. How would you ensure the proper functioning of the pneumatic jack?

To ensure the proper functioning of the pneumatic jack, I would follow these steps:

- Inspect the jack for any visible damage or leaks.

- Check the air pressure and adjust it to the manufacturer’s specifications.

- Lubricate all moving parts according to the maintenance schedule.

- Test the jack under a load to verify its functionality.

2. What are the safety precautions that you need to take while operating a pneumatic jack?

- Never exceed the rated capacity of the jack.

- Always use a stable and level surface when operating the jack.

- Keep your hands and feet away from moving parts.

- Never use a jack to lift a load that is unbalanced or unstable.

- Always use a safety chain or other means to secure the load before lifting.

3. How would you troubleshoot a pneumatic jack that is not lifting properly?

To troubleshoot a pneumatic jack that is not lifting properly, I would follow these steps:

- Check the air pressure and adjust it to the manufacturer’s specifications.

- Check for any leaks in the air lines or fittings.

- Inspect the hydraulic cylinder and ram for any damage or wear.

- Check the release valve to make sure it is not stuck open.

- Lubricate all moving parts according to the maintenance schedule.

4. What are the different types of pneumatic jacks and what are their applications?

- Single-acting jacks: These jacks can only lift a load in one direction. They are typically used for lifting heavy objects or for applying force in a specific direction.

- Double-acting jacks: These jacks can lift a load in both directions. They are typically used for lifting or lowering objects or for applying force in both directions.

- Hollow-plunger jacks: These jacks have a hollow plunger that allows them to be used in tight spaces. They are typically used for lifting objects that have a small footprint.

5. What are the maintenance requirements for a pneumatic jack?

- Regular inspection for any visible damage or leaks.

- Checking and adjusting the air pressure according to the manufacturer’s specifications.

- Lubricating all moving parts according to the maintenance schedule.

- Testing the jack under a load to verify its functionality.

6. What would you do if you noticed a leak in a pneumatic jack?

If I noticed a leak in a pneumatic jack, I would follow these steps:

- Identify the location of the leak.

- Turn off the air supply to the jack.

- Repair the leak using the appropriate tools and materials.

- Test the jack under a load to verify that the leak has been repaired.

7. How would you determine the weight of a load that you need to lift with a pneumatic jack?

To determine the weight of a load that I need to lift with a pneumatic jack, I would use the following formula:

Weight of load = Pressure (psi) x Area of piston (in2)

8. What is the difference between a pneumatic jack and a hydraulic jack?

- Pneumatic jacks use compressed air to generate force, while hydraulic jacks use hydraulic fluid.

- Pneumatic jacks are typically lighter and more portable than hydraulic jacks.

- Hydraulic jacks can generate more force than pneumatic jacks, but they are also more complex and expensive.

9. What is the maximum pressure that a pneumatic jack can operate at?

The maximum pressure that a pneumatic jack can operate at is determined by the manufacturer. However, most pneumatic jacks have a maximum pressure rating of 100 psi.

10. What are the advantages of using a pneumatic jack?

- Lightweight and portable: Pneumatic jacks are typically lighter and more portable than hydraulic jacks, making them easier to use in tight spaces.

- Corrosion-resistant: Pneumatic jacks are made from corrosion-resistant materials, making them ideal for use in wet or damp environments.

- Cost-effective: Pneumatic jacks are typically less expensive than hydraulic jacks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pneumatic Jack Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pneumatic Jack Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pneumatic Jack Operators are responsible for the safe and efficient operation of pneumatic jacks in various industrial settings, ensuring that heavy loads are lifted, lowered, and moved with precision.

1. Equipment Handling

Operate pneumatic jacks, including portable and stationary models, ensuring proper functioning and maintenance.

- Inspect jacks regularly for any leaks, damage, or wear, ensuring timely repairs or replacements.

- Follow prescribed operating procedures for jack setup, load handling, and jack removal, adhering to safety protocols.

2. Load Management

Calculate and verify load weights, ensuring they do not exceed the rated capacity of the pneumatic jack.

- Position the jack correctly under the load, ensuring stability and even distribution of force.

- Operate the jack lever or controls smoothly and precisely, raising and lowering loads safely.

3. Rigging and Equipment Setup

Rig slings, chains, or other attachments to the load, ensuring secure and balanced lifting.

- Inspect rigging equipment regularly for any damage or defects, ensuring timely replacements.

- Collaborate with other operators or rigging personnel to ensure proper load handling and movement.

4. Safety and Compliance

Prioritize safety in all operations, following established procedures and regulations.

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and steel-toed boots.

- Monitor the work area for potential hazards, reporting any unsafe conditions immediately.

Interview Tips

Preparing for an interview for a Pneumatic Jack Operator position requires thorough research, practice, and understanding of the industry and the expected job responsibilities. Here are some essential tips to help candidates ace their interview:

1. Research the Company and the Role

Before the interview, candidates should thoroughly research the company they are applying to, including its industry, size, culture, and recent news. Additionally, it is crucial to study the specific job description and responsibilities to gain a clear understanding of the expectations for the role.

- Visit the company’s website and social media pages to learn more about its mission, values, and current projects.

- Read industry-specific publications and articles to stay abreast of the latest trends and best practices in the field.

2. Highlight Relevant Skills and Experience

Candidates should prepare to discuss their relevant skills and experience that align with the job requirements. It is important to focus on transferable skills and provide specific examples to demonstrate their proficiency.

- Emphasize experience in operating pneumatic jacks or similar equipment, including load handling and rigging procedures.

- Highlight any knowledge of safety regulations and industry best practices for heavy lifting and load movement.

3. Showcase Safety Consciousness

Safety is paramount for Pneumatic Jack Operators. Candidates should demonstrate their commitment to safety by discussing their adherence to established procedures, use of PPE, and ability to identify potential hazards.

- Provide examples of how they have implemented safety measures to prevent accidents or injuries in previous roles.

- Discuss their understanding of the importance of maintaining a clean and organized work area to minimize risks.

4. Prepare for Technical Questions

Interviews for Pneumatic Jack Operator positions often include technical questions to assess the candidate’s knowledge of the equipment and industry. Candidates should prepare for questions related to:

- Types of pneumatic jacks and their applications

- Load calculation and weight distribution

- Rigging and attachment methods

- Safety protocols and emergency procedures

5. Practice Common Interview Questions

In addition to technical questions, candidates should prepare for common interview questions that assess their communication skills, teamwork abilities, and career goals.

- Tell me about yourself and why you are interested in this role.

- Describe a time you faced a challenge in a previous job and how you overcame it.

- What are your strengths and weaknesses as a Pneumatic Jack Operator?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pneumatic Jack Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!