Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pneumatic Riveter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

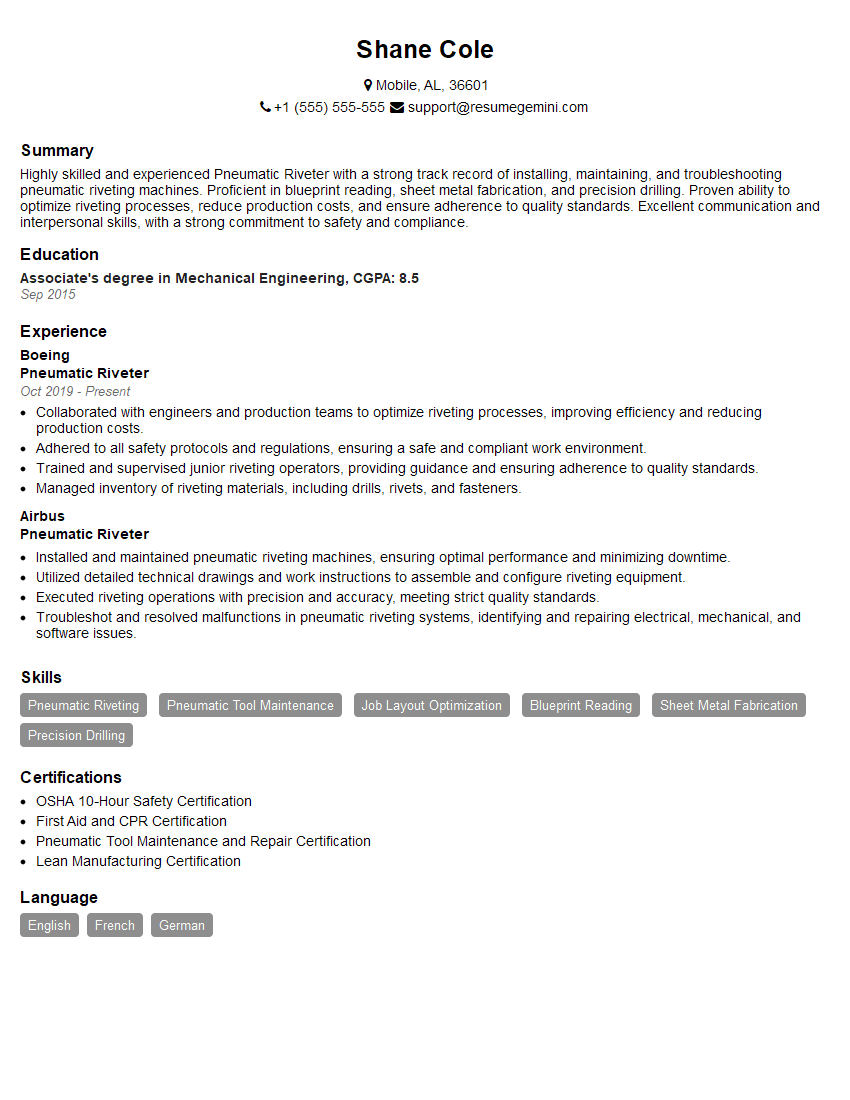

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pneumatic Riveter

1. Describe the working principle of a pneumatic riveter and its components?

- A pneumatic riveter is a handheld tool that uses compressed air to drive rivets into metal or other materials.

- The main components of a pneumatic riveter are the air motor, the rivet setter, and the trigger.

- The air motor converts the compressed air into mechanical energy, which is then used to drive the rivet setter.

- The rivet setter is a plunger that moves up and down to drive the rivet into the material.

- The trigger is used to control the flow of compressed air to the air motor.

2. What are the different types of pneumatic riveters?

Types of riveters

Based on construction:

- Inline Riveter

- Right-Angle Riveter

Based on drive system:

- Radial Riveter

- Hammer Riveter

- Squeezer Riveter

- Peen Riveter

of the answer

- Inline riveters are the most common type of pneumatic riveter. They are lightweight and easy to use, and they can be used to drive rivets of all sizes.

- Right-angle riveters are designed to be used in tight spaces. They are heavier than inline riveters, but they offer more power and can be used to drive larger rivets.

3. What are the safety precautions that should be taken when using a pneumatic riveter?

- Wear safety glasses and earplugs when using a pneumatic riveter.

- Make sure that the riveter is properly lubricated.

- Do not use the riveter if it is damaged.

- Keep the riveter away from children.

4. How do you maintain a pneumatic riveter?

- Clean the riveter regularly with a soft cloth.

- Lubricate the riveter regularly with a light oil.

- Inspect the riveter regularly for damage.

- If the riveter is damaged, do not use it and have it repaired by a qualified technician.

5. What are the common problems that can occur with a pneumatic riveter?

- The riveter may not drive the rivets properly.

- The riveter may leak air.

- The riveter may vibrate excessively.

- The riveter may be damaged.

6. How do you troubleshoot a pneumatic riveter?

- If the riveter is not driving the rivets properly, check the air pressure and make sure that the riveter is properly lubricated.

- If the riveter is leaking air, check the seals and gaskets.

- If the riveter is vibrating excessively, check the balance of the riveter.

- If the riveter is damaged, do not use it and have it repaired by a qualified technician.

7. What are the advantages of using a pneumatic riveter?

- Pneumatic riveters are lightweight and easy to use.

- They can be used to drive rivets of all sizes.

- They are relatively inexpensive.

- They are durable and can withstand heavy use.

8. What are the disadvantages of using a pneumatic riveter?

- Pneumatic riveters can be noisy.

- They can be dangerous if they are not used properly.

- They require a source of compressed air.

9. What is the difference between a pneumatic riveter and a hydraulic riveter?

- Pneumatic riveters use compressed air to drive rivets, while hydraulic riveters use hydraulic pressure.

- Pneumatic riveters are generally lighter and more portable than hydraulic riveters.

- Hydraulic riveters are generally more powerful than pneumatic riveters.

10. What is the difference between a pneumatic riveter and an electric riveter?

- Pneumatic riveters use compressed air to drive rivets, while electric riveters use electricity.

- Pneumatic riveters are generally more powerful than electric riveters.

- Pneumatic riveters require a source of compressed air, while electric riveters do not.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pneumatic Riveter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pneumatic Riveter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Pneumatic Riveter, you will be responsible for operating a pneumatic riveting machine to assemble various components by setting and driving rivets to fasten them together. Your duties will primarily involve:

1. Riveting Operations

Operate pneumatic riveting machine to set and drive rivets into materials.

- Select appropriate rivet size and type for the job.

- Position and hold materials securely while driving rivets.

2. Job Setup and Preparation

Set up and prepare workstation for riveting operations.

- Install and adjust riveting machine as per job requirements.

- Load rivets into the machine and ensure proper feeding.

3. Quality Control

Inspect riveted joints for defects, such as loose rivets or improper alignment.

- Use measuring tools and gauges to verify the accuracy and precision of riveted joints.

- Identify and resolve any quality issues promptly.

4. Safety and Maintenance

Maintain a clean and safe work area.

- Follow established safety procedures when operating the riveting machine.

- Perform regular maintenance and cleaning of the machine to ensure optimal performance.

Interview Tips

To ace your interview for the Pneumatic Riveter position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and the specific requirements of the Pneumatic Riveter role. This will demonstrate your interest and preparation.

- Visit the company website.

- Check industry news and articles.

2. Highlight Relevant Skills and Experience

Emphasize your technical expertise in operating pneumatic riveting machines, as well as your understanding of quality control principles. Showcase your attention to detail and commitment to safety.

- Describe specific projects where you used pneumatic riveting.

- Quantify your results with metrics, such as accuracy and efficiency.

3. Prepare for Common Interview Questions

Be prepared to answer questions about your rivet setting techniques, safety measures, and problem-solving abilities.

- Practice answering standard interview questions related to your skills and experience.

- Prepare examples of how you handled challenges in previous riveting roles.

4. Ask Informed Questions

Ask thoughtful questions during the interview to show your engagement and curiosity. This could include inquiring about the company’s quality standards or the specific projects you would be working on.

- Prepare a list of questions ahead of time.

- Tailor your questions to the specific company and job responsibilities.

Next Step:

Now that you’re armed with the knowledge of Pneumatic Riveter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pneumatic Riveter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini