Are you gearing up for a career in Pneumatic Tube Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pneumatic Tube Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

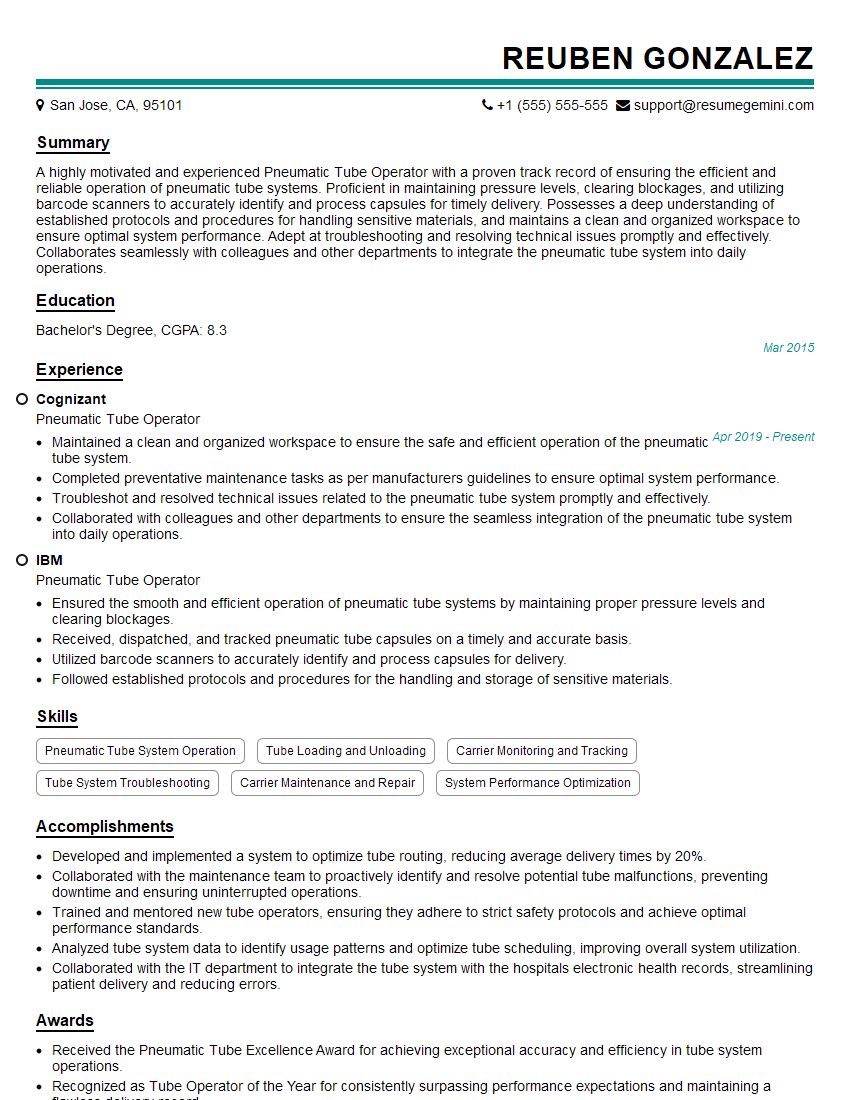

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pneumatic Tube Operator

1. What are the key responsibilities of a Pneumatic Tube Operator?

As a Pneumatic Tube Operator, my responsibilities would include:

- Operating and maintaining the pneumatic tube system to ensure efficient and timely delivery of items

- Loading, unloading, and routing carriers through the system

- Monitoring the system for any malfunctions or blockages and taking corrective actions

- Maintaining accurate records of all transactions and system maintenance

2. Describe the different types of pneumatic tube systems and their applications.

There are several types of pneumatic tube systems, each with specific applications:

Station-to-station systems

- Connect two or more fixed stations

- Used in hospitals, banks, and retail stores

Networked systems

- Connect multiple stations across a larger area

- Used in factories, warehouses, and distribution centers

Automated systems

- Use computer controls to manage the system

- Track and sort carriers, and provide real-time monitoring

3. What are the safety precautions that must be observed when working with a pneumatic tube system?

To ensure safety when working with a pneumatic tube system, I would adhere to the following precautions:

- Wear appropriate safety gear, including gloves and safety glasses

- Never put hands or fingers into the carrier openings

- Be aware of the location of emergency stop switches

- Follow all established operating procedures and protocols

4. How would you troubleshoot a pneumatic tube system if a carrier becomes jammed?

If a carrier becomes jammed, I would follow these troubleshooting steps:

- Check for any visible obstructions or blockages in the tube

- Try to manually dislodge the carrier by gently pushing or pulling it

- If manual dislodging fails, consult the system manual for specific troubleshooting instructions

- If the issue persists, contact a qualified technician for assistance

5. What are the different types of carriers used in pneumatic tube systems, and what are their respective purposes?

Pneumatic tube systems use various types of carriers, each designed for specific purposes:

- Standard carriers: Used to transport general items such as documents, samples, and small parts

- Temperature-controlled carriers: Maintains specific temperature ranges for transporting sensitive items such as medical specimens or food

- High-security carriers: Equipped with locking mechanisms for transporting confidential or valuable items

- Custom carriers: Designed to accommodate specific item shapes or sizes, such as oversized documents or fragile equipment

6. How do you ensure the confidentiality of items transported through the pneumatic tube system?

To maintain confidentiality, I would implement the following measures:

- Use sealed and tamper-proof carriers

- Restrict access to the system and carrier loading areas

- Train staff on proper handling and security procedures

- Establish clear protocols for handling sensitive or confidential items

7. How would you handle a situation where a carrier is lost within the system?

If a carrier is lost, I would follow these steps:

- Check all stations and work areas for the missing carrier

- Review system logs and monitor carrier tracking data

- Contact other departments or areas that may have received the carrier

- If the carrier cannot be located, report the incident to a supervisor and initiate an investigation

8. What are the key performance indicators (KPIs) for a Pneumatic Tube Operator?

As a Pneumatic Tube Operator, my performance would be measured based on the following KPIs:

- System uptime: Percentage of time that the system is operational and available for use

- Carrier delivery time: Average time taken for a carrier to travel from one station to another

- Carrier throughput: Number of carriers processed per hour or shift

- System efficiency: Ratio of successful carrier deliveries to total carrier attempts

9. What are the potential risks associated with working with a pneumatic tube system, and how do you mitigate them?

Potential risks associated with pneumatic tube systems include:

- Carrier jams: Blockages or obstructions can cause carriers to get stuck, disrupting system operations

- System leaks: Damage to tubes or fittings can lead to air leaks, affecting system performance

- Safety hazards: Moving carriers can pose a risk to personnel if proper precautions are not taken

To mitigate these risks, I would:

- Perform regular system inspections and maintenance

- Follow established safety protocols and wear appropriate protective gear

- Train staff on proper operating procedures and emergency response

10. How do you stay up-to-date on advancements in pneumatic tube technology?

To stay abreast of advancements:

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Participate in online forums and discussions

- Network with other professionals in the field

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pneumatic Tube Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pneumatic Tube Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The primary role of a Pneumatic Tube Operator is to operate and maintain pneumatic tube systems, which are used for rapid and secure transportation of materials, documents, and other items within a facility.

1. System Operation

Operate pneumatic tube systems to send and receive carriers containing items.

- Load and unload carriers.

- Monitor system performance and adjust settings as necessary.

2. System Maintenance

Maintain and troubleshoot pneumatic tube systems to ensure optimal functionality.

- Inspect and clean system components.

- Repair or replace faulty parts.

3. Carrier Management

Manage the flow of carriers through the system to prevent congestion and ensure timely delivery.

- Track and locate carriers.

- Resolve carrier malfunctions.

4. Safety and Compliance

Follow established safety procedures and adhere to all applicable regulations.

- Wear appropriate safety gear.

- Report any safety hazards or concerns.

Interview Tips

To prepare for an interview for a Pneumatic Tube Operator position, consider the following tips:

1. Research the Company and Role

Learn about the company’s industry, size, and culture. Study the job description thoroughly to understand the specific requirements and responsibilities of the role.

- Example: Research the hospital’s patient care philosophy and the role of pneumatic tube systems in improving patient outcomes.

2. Practice System Knowledge

Become familiar with the principles of pneumatic tube systems, including their components, operation, and troubleshooting procedures. Consider reading industry articles or manuals to enhance your technical understanding.

- Example: Describe the different types of carriers used in a pneumatic tube system and their applications.

3. Highlight Safety and Compliance

Emphasize your commitment to safety and compliance. Understand the importance of following established protocols and adhering to regulations in a healthcare or laboratory setting.

- Example: Describe your experience in managing hazardous materials or handling sensitive patient information in accordance with industry standards.

4. Showcase Problem-Solving Skills

Provide examples of your problem-solving abilities and how you have resolved technical issues or operational challenges in previous roles.

- Example: Share a situation where you diagnosed and repaired a malfunctioning pneumatic tube system, ensuring uninterrupted operations.

5. Prepare Behavioral Questions

Research common behavioral interview questions and prepare thoughtful responses that demonstrate your work ethic, teamwork skills, and ability to handle pressure.

- Example: Describe a time when you exceeded expectations in a fast-paced and demanding work environment.

Next Step:

Now that you’re armed with the knowledge of Pneumatic Tube Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pneumatic Tube Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini