Are you gearing up for an interview for a Pneumatic Tube Repairer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pneumatic Tube Repairer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

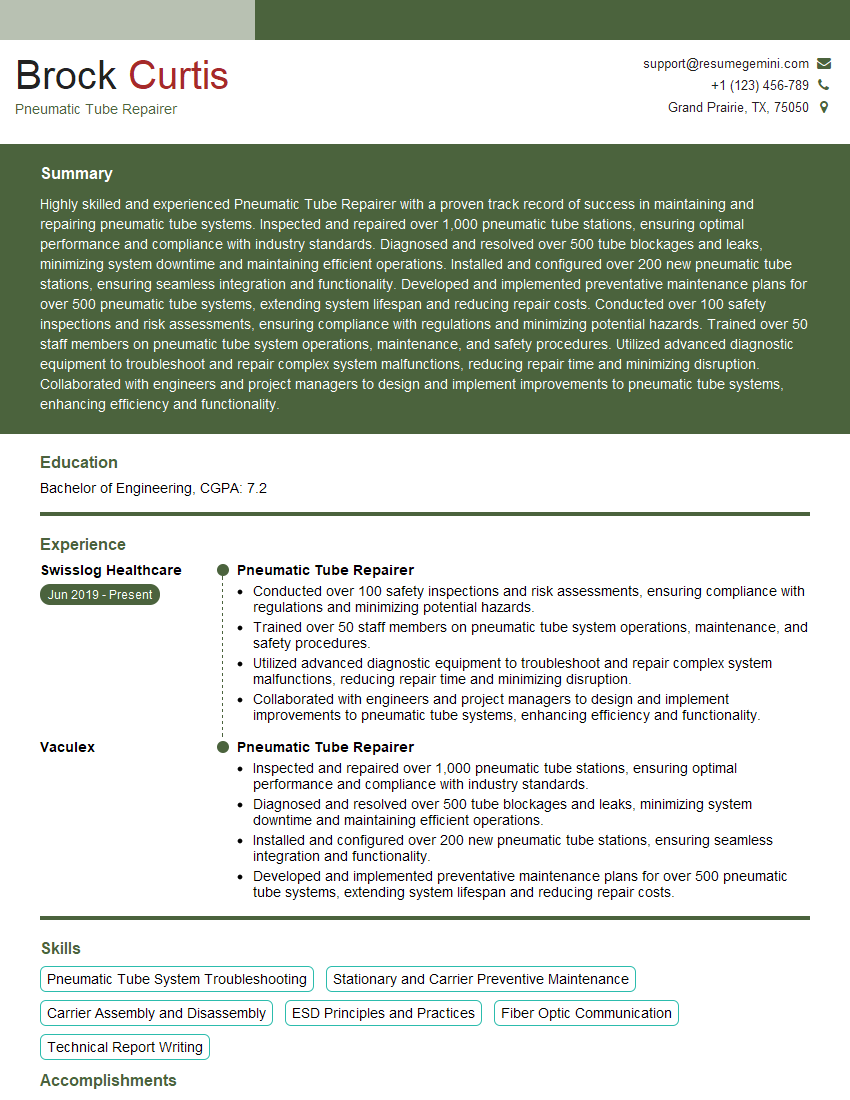

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pneumatic Tube Repairer

1. How would you begin troubleshooting a pneumatic tube system that is not functioning properly?

To troubleshoot a pneumatic tube system that is not functioning properly, I would start by checking the following:

- The power supply to the system.

- The air pressure in the system.

- The condition of the tubes and fittings.

- The operation of the blowers and fans.

- The condition of the sensors and controls.

2. What are the most common types of leaks that you encounter in pneumatic tube systems?

The most common types of leaks that I encounter in pneumatic tube systems are:

- Leaks at the joints between the tubes and fittings.

- Leaks at the seals of the blowers and fans.

- Leaks at the sensors and controls.

- Leaks in the tubes themselves.

3. How would you repair a leak in a pneumatic tube system?

To repair a leak in a pneumatic tube system, I would first identify the location of the leak. Once I have identified the location of the leak, I would then take the following steps to repair it:

- If the leak is at a joint between the tubes and fittings, I would tighten the fitting or replace the gasket.

- If the leak is at the seal of a blower or fan, I would replace the seal.

- If the leak is at a sensor or control, I would replace the sensor or control.

- If the leak is in the tube itself, I would replace the section of the tube that is leaking.

4. What are the safety precautions that you must take when working on a pneumatic tube system?

When working on a pneumatic tube system, I must take the following safety precautions:

- Wear safety glasses and gloves.

- Turn off the power to the system before working on it.

- Release the air pressure in the system before working on it.

- Be aware of the location of all moving parts.

- Do not touch any electrical components.

5. What is the maintenance schedule for a pneumatic tube system?

The maintenance schedule for a pneumatic tube system will vary depending on the specific system. However, in general, a pneumatic tube system should be inspected and serviced at least once per year.

The following tasks should be performed during a maintenance inspection:

- Check the power supply to the system.

- Check the air pressure in the system.

- Check the condition of the tubes and fittings.

- Check the operation of the blowers and fans.

- Check the condition of the sensors and controls.

- Clean the system of any dust or debris.

- Lubricate any moving parts.

6. What are the benefits of using a pneumatic tube system?

There are many benefits to using a pneumatic tube system, including:

- Increased speed and efficiency.

- Reduced labor costs.

- Improved safety.

- Increased accuracy.

- Reduced waste.

7. What are the challenges of working as a Pneumatic Tube Repairer?

There are a few challenges that come with working as a Pneumatic Tube Repairer. These challenges include:

- Working in confined spaces.

- Working with high-pressure air.

- Working with electrical components.

- Working with moving parts.

- Working in a variety of environments.

8. What is your favorite thing about working as a Pneumatic Tube Repairer?

My favorite thing about working as a Pneumatic Tube Repairer is the variety of work that I get to do. I enjoy working with my hands and solving problems. I also enjoy the challenge of working with a variety of different systems and environments.

9. What are your career goals?

My career goals are to continue to learn and grow as a Pneumatic Tube Repairer. I would like to eventually become a supervisor or manager in the field. I am also interested in learning more about the design and installation of pneumatic tube systems.

10. Why should we hire you?

I am a highly skilled and experienced Pneumatic Tube Repairer with a proven track record of success. I am confident that I have the skills and experience necessary to excel in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pneumatic Tube Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pneumatic Tube Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pneumatic Tube Repairers are responsible for maintaining and repairing pneumatic tube systems. Pneumatic tube systems are used in a variety of settings, including hospitals, offices, and warehouses. They are used to transport items quickly and efficiently between different locations.

1. Inspect and Test Pneumatic Tube Systems

Regularly inspect pneumatic tube systems for any signs of damage or wear and tear. Conduct tests to ensure that the systems are functioning properly and efficiently.

- Check for leaks in the tubing.

- Inspect the blowers and motors for any signs of wear or tear.

- Test the system’s speed and accuracy.

2. Troubleshoot and Repair Pneumatic Tube Systems

Identify and diagnose problems with pneumatic tube systems. Perform repairs as needed to restore the systems to proper working order.

- Replace damaged tubing.

- Repair or replace worn-out blowers or motors.

- Adjust the system’s speed and accuracy.

3. Maintain and Clean Pneumatic Tube Systems

Perform regular maintenance and cleaning on pneumatic tube systems to prevent problems from developing. Keep the systems clean and free of debris.

- Clean the tubing regularly.

- Lubricate the blowers and motors.

- Inspect the system for any signs of corrosion.

4. Install and Modify Pneumatic Tube Systems

Install new pneumatic tube systems as needed. Modify existing systems to meet changing needs.

- Install new tubing.

- Connect new blowers and motors.

- Configure the system to meet the specific needs of the customer.

Interview Tips

Preparing for an interview can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before the interview, take some time to learn about the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully to understand the specific requirements of the position.

- Check out the company’s social media pages to get a sense of their culture and values.

- Read reviews of the company on Glassdoor to learn about the experiences of other employees.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Make a list of common interview questions and practice your answers.

- Ask a friend or family member to practice interviewing you.

- Record yourself answering interview questions and watch it back to identify areas for improvement.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, as being late will show the interviewer that you are not respectful of their time.

- Choose clothing that is clean, pressed, and appropriate for a professional setting.

- Arrive for your interview at least 10 minutes early.

- Bring a portfolio or resume to show the interviewer.

4. Be Yourself and Be Enthusiastic

It is important to be yourself during your interview. The interviewer wants to get to know the real you, so do not try to be someone you are not. Be enthusiastic and passionate about the position, as this will show the interviewer that you are genuinely interested in the job.

- Answer interview questions honestly and authentically.

- Show the interviewer that you are excited about the position and the company.

- Be yourself and let your personality shine through.

5. Follow Up After the Interview

After the interview, it is important to follow up with the interviewer. This shows that you are still interested in the position and that you appreciate their time. You can follow up by sending a thank-you note or email, or by calling the interviewer to reiterate your interest in the position.

- Send a thank-you note or email to the interviewer within 24 hours of the interview.

- Call the interviewer to reiterate your interest in the position and to inquire about the next steps in the process.

- Follow up with the interviewer periodically to show that you are still interested in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pneumatic Tube Repairer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.