Feeling lost in a sea of interview questions? Landed that dream interview for Pocket Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pocket Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

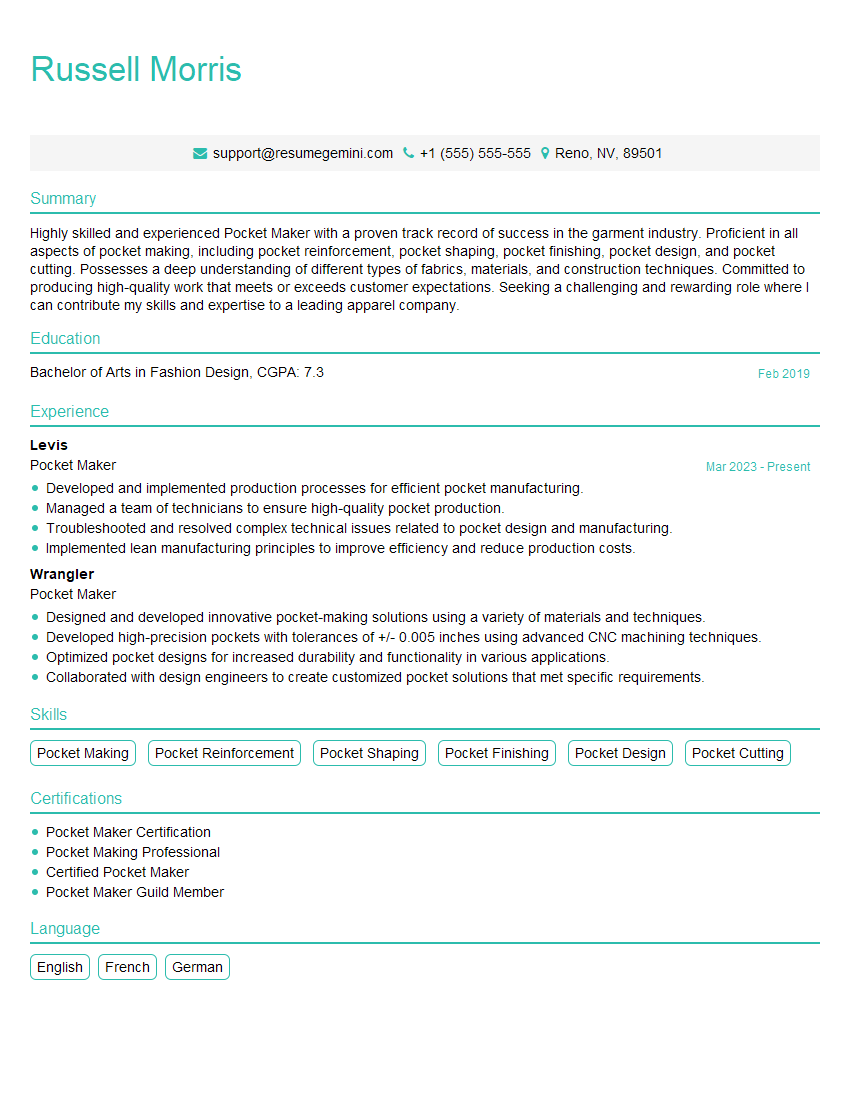

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pocket Maker

1. Describe the different types of materials used in Pocket Makers and the advantages and disadvantages of each?

- ABS (Acrylonitrile Butadiene Styrene): High strength, durability, and good heat resistance. However, it can be brittle and prone to warping.

- PLA (Polylactic Acid): Biodegradable, non-toxic, and easy to print. However, it has lower strength and heat resistance than ABS.

- PETG (Polyethylene Terephthalate Glycol): High strength, good flexibility, and chemical resistance. However, it can require higher printing temperatures and can be more challenging to print with.

- TPU (Thermoplastic Polyurethane): High flexibility, impact resistance, and abrasion resistance. However, it can be more difficult to print with and requires specialized equipment.

2. Explain the principles behind Fused Deposition Modeling (FDM) technology used in Pocket Makers and discuss its limitations and strengths?

Strengths

- Wide range of materials

- Relatively low cost

- Easy to use

Limitations

- Limited resolution

- Can be slow

- Can require post-processing

3. Discuss the importance of bed leveling in Pocket Makers and explain the different methods used to achieve it?

Bed leveling ensures that the build platform is perfectly parallel to the print head, which is crucial for successful printing. Methods include:

- Manual leveling: Using a feeler gauge or paper to manually adjust the bed height.

- Automated leveling: Using sensors or probes to automatically adjust the bed height.

- Mesh leveling: Creating a map of the bed’s surface and compensating for any unevenness.

4. Describe the slicer software workflow and its role in preparing 3D models for printing with Pocket Makers?

The slicer software workflow involves:

- Importing the 3D model: Loading the 3D model into the slicer software.

- Slicing the model: Dividing the model into thin layers that the printer can build.

- Generating G-code: Creating a set of instructions for the printer to follow.

- Saving the G-code file: Exporting the instructions to a file that the printer can read.

5. Explain the different types of supports used in Pocket Maker printing and their purpose?

- Basic supports: Simple structures that provide support for overhanging parts.

- Tree supports: Complex branching structures that minimize material usage and improve print quality.

- Manual supports: Custom supports added manually to provide additional support for specific areas.

6. Describe the maintenance procedures for Pocket Makers, including cleaning, calibration, and troubleshooting?

Maintenance procedures include:

- Cleaning: Regularly cleaning the nozzle, print bed, and other components to prevent clogs and ensure proper functionality.

- Calibration: Calibrating the printer to ensure precise movements and bed leveling.

- Troubleshooting: Identifying and resolving common printing issues, such as clogs, bed adhesion problems, or filament tangles.

7. Discuss the safety precautions to consider when operating Pocket Makers?

- Use in a well-ventilated area: Fumes released during printing can be harmful.

- Keep the printer stable: Ensure the printer is placed on a sturdy surface to prevent vibrations.

- Handle the heated bed with caution: The bed can reach high temperatures during printing.

- Unplug the printer before maintenance: Always disconnect the printer from power before performing any maintenance or repairs.

8. Explain the benefits of using Pocket Makers for rapid prototyping and small-scale production?

- Fast prototyping: Quick turnaround time for creating physical objects from digital designs.

- Cost-effective: Lower costs compared to traditional manufacturing methods for small-scale production.

- Customized products: Ability to create unique and customized products on demand.

- Design iterations: Flexibility to iterate on designs quickly and easily.

9. Describe the emerging trends and advancements in Pocket Maker technology?

- Multi-material printing: Printing with multiple materials in a single build.

- Higher resolution printing: Improved print quality and finer details.

- Cloud connectivity: Remote monitoring and control of printers.

- AI-assisted printing: Automated optimization of print settings and error detection.

10. Discuss your experience with Pocket Makers and how it relates to the requirements of this role?

Highlight relevant skills and projects, such as:

- Designing and slicing 3D models for Pocket Maker printing

- Maintaining and calibrating Pocket Makers

- Troubleshooting and resolving common printing issues

- Using Pocket Makers for rapid prototyping or small-scale production

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pocket Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pocket Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pocket Makers are responsible for the design, development, and production of small, foldable, portable devices. These devices range from smartphones and laptops to tablets and e-readers. Pocket Makers must have a strong understanding of the latest technologies and trends in the electronics industry. They must also be able to work independently and as part of a team.

1. Product Design

Pocket Makers work with industrial designers to create new products. They develop the overall concept for the product, including its size, shape, and features. They also work with engineers to develop the product’s hardware and software.

- Conduct market research to identify customer needs.

- Develop product concepts and specifications.

- Create prototypes and conduct user testing.

2. Engineering

Pocket Makers work with engineers to develop the product’s hardware and software. They ensure that the product is reliable, efficient, and easy to use. They also work with manufacturing teams to ensure that the product can be produced at scale.

- Develop product hardware and software.

- Test and debug products.

- Work with manufacturing teams to ensure that products can be produced at scale.

3. Production

Pocket Makers work with production teams to ensure that products are manufactured to the highest quality standards. They also work with logistics teams to ensure that products are delivered to customers on time and in good condition.

- Work with production teams to ensure that products are manufactured to the highest quality standards.

- Work with logistics teams to ensure that products are delivered to customers on time and in good condition.

- Monitor production processes and make adjustments as needed.

4. Marketing

Pocket Makers work with marketing teams to develop and execute marketing campaigns for new products. They also work with sales teams to train them on the product’s features and benefits.

- Develop and execute marketing campaigns for new products.

- Work with sales teams to train them on the product’s features and benefits.

- Monitor market trends and identify new opportunities for product development.

Interview Tips

Preparing for an interview for a Pocket Maker position can be overwhelming, but by following these simple tips, you can increase your chances of success.

1. Research the Company and the Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you prepare for the specific questions that you may be asked during your interview.

- Visit the company’s website and social media pages.

- Read news articles and blog posts about the company.

- Talk to people who work at the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with product development?

- What are your salary expectations?

3. Prepare Questions for the Interviewer

At the end of the interview, you will be given the opportunity to ask the interviewer questions. This is a great opportunity to learn more about the position and the company. It is also a good way to show the interviewer that you are interested in the position and that you have done your research.

- What are the biggest challenges facing the company right now?

- What is the company’s culture like?

- What are the opportunities for advancement?

- What is the company’s policy on work-life balance?

4. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Arrive on time for your interview.

5. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and genuine, and let your personality shine through.

- Be honest and genuine.

- Let your personality shine through.

- Be confident and enthusiastic.

Next Step:

Now that you’re armed with the knowledge of Pocket Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pocket Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini