Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Polishing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

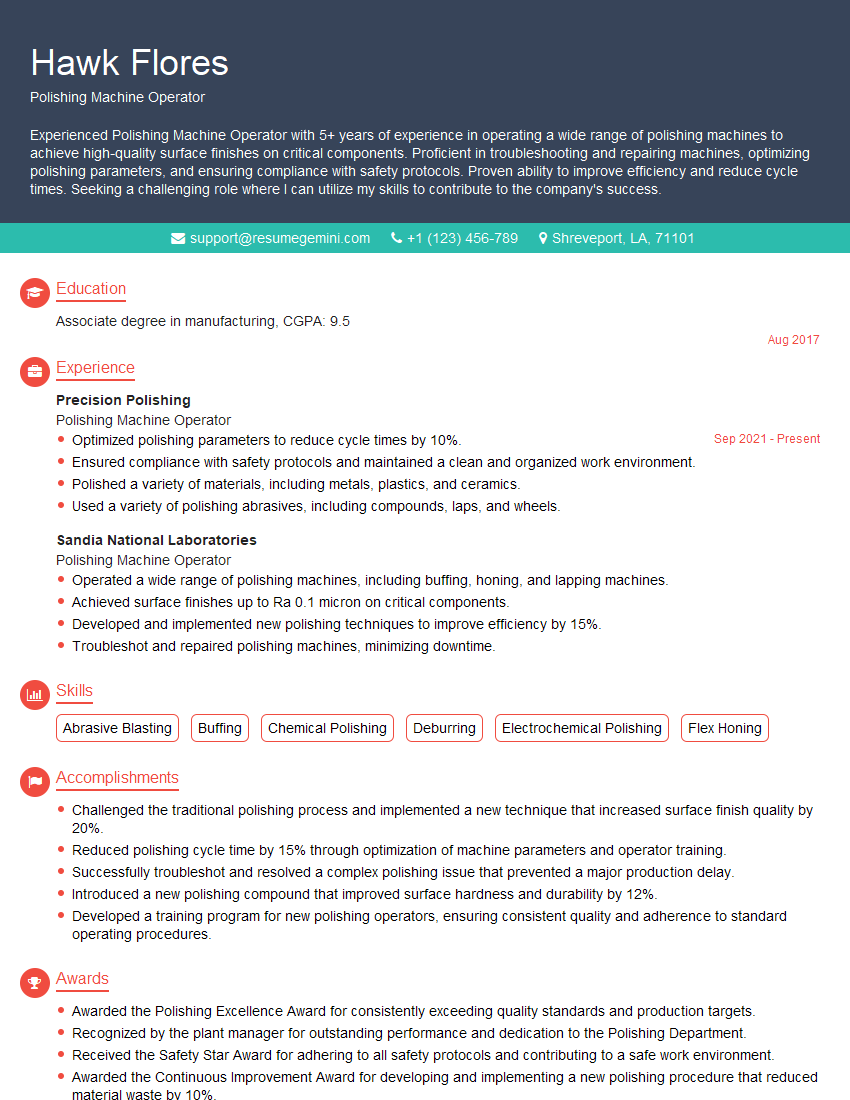

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Polishing Machine Operator

1. Explain the basic principles of polishing machine operations?

- Polishing machine operations involve removing imperfections from a surface to achieve a desired smoothness and finish.

- The process utilizes rotating abrasive wheels or belts coated with polishing compounds.

- The machine’s speed, pressure, and abrasive type are carefully controlled to prevent damage to the surface.

2. Describe the different types of polishing machines and their applications

Belt polishing machines

- Suitable for flat or slightly curved surfaces

- Use abrasive belts of varying grits to achieve different finishes

Wheel polishing machines

- Used for polishing both flat and contoured surfaces

- Offer precise control over pressure and angle

Buffing machines

- Employed for producing high-gloss finishes

- Utilize soft, flexible wheels coated with polishing compounds

3. Explain the safety precautions that must be followed when operating polishing machines?

- Wear appropriate safety gear, including gloves, eye protection, and respiratory mask.

- Ensure the machine is properly grounded and guards are in place.

- Inspect the abrasive wheels or belts for damage before use.

- Never operate the machine while under the influence of drugs or alcohol.

4. How do you determine the correct abrasive type and grit size for a particular polishing job?

- Consider the material being polished and the desired finish.

- Start with a coarse abrasive for initial stock removal, gradually transitioning to finer grits for a smoother finish.

- Test different abrasives and grits on a small area to determine the optimal combination.

5. Describe the process of preparing a surface for polishing?

- Clean the surface to remove any dirt, grease, or debris.

- Sand or grind the surface to create a uniform base.

- Apply a primer or sealant if necessary to enhance adhesion.

6. Explain how to maintain polishing machines to ensure optimal performance?

- Regularly clean and inspect the machine, including the abrasive wheels or belts.

- Check and adjust the tension of belts or wheels to prevent slippage.

- Lubricate moving parts as per manufacturer’s recommendations.

7. Describe the different types of polishing compounds and their properties?

- Abrasive compounds: Contain abrasive particles to remove material and create a smooth surface.

- Non-abrasive compounds: Used for final polishing and buffing to achieve a high gloss.

- Water-based compounds: Environmentally friendly and less messy than oil-based compounds.

- Oil-based compounds: Provide a longer working time and produce a smoother finish.

8. Explain the importance of coolant in polishing operations?

- Coolant lubricates the polishing process, reducing friction and heat buildup.

- It removes swarf and prevents clogging of the abrasive surface.

- Coolant improves the surface finish by preventing overheating and discoloration.

9. Describe the different types of surface finishes that can be achieved through polishing?

- Matte finish: A dull, non-reflective surface.

- Satin finish: A slightly reflective surface with a subtle sheen.

- Gloss finish: A highly reflective, mirror-like surface.

- Supergloss finish: An exceptionally reflective surface, often used in optical applications.

10. Explain the role of quality control in polishing operations?

- Ensures that polished surfaces meet the required specifications.

- Involves regular inspection and testing of surface roughness, finish, and other quality parameters.

- Helps identify and correct any deviations from the desired results.

- Maintains a high level of product quality and customer satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Polishing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Polishing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Polishing Machine Operators are responsible for operating polishing machines to polish and buff metal, plastic, and other surfaces to achieve a smooth and shiny finish. They must ensure that the machines are properly set up and maintained, and that the materials being polished are handled safely. Some of the key job responsibilities of Polishing Machine Operators include:

1. Machine Setup and Maintenance

Polishing Machine Operators must set up and maintain their machines properly. This includes ensuring that the machine is properly calibrated, that the correct abrasives and polishing compounds are being used, and that the machine is clean and free of debris.

- Set up and calibrate polishing machines according to specifications.

- Select and install appropriate abrasives and polishing compounds.

- Maintain machines in good working order by performing regular cleaning and maintenance tasks.

2. Material Handling

Polishing Machine Operators must be able to handle materials safely and efficiently. This includes loading and unloading the machine, as well as moving materials around the work area.

- Load and unload materials from polishing machines.

- Move materials around the work area safely and efficiently.

- Inspect materials for defects before and after polishing.

3. Polishing and Buffing

Polishing Machine Operators must be able to operate the machine safely and efficiently. This includes knowing how to adjust the machine’s settings, as well as how to hold the materials being polished.

- Operate polishing machines to achieve a smooth and shiny finish on surfaces.

- Adjust machine settings to achieve desired results.

- Hold materials securely while polishing to avoid accidents.

4. Quality Control

Polishing Machine Operators must be able to inspect materials before and after polishing to ensure that they meet quality standards. They must also be able to identify and correct any defects.

- Inspect materials before and after polishing to ensure quality standards are met.

- Identify and correct any defects in the polishing process.

- Maintain records of polishing operations for quality control purposes.

Interview Tips

Preparing for an interview for a Polishing Machine Operator position can help you increase your chances of getting the job. By taking the time to learn about the company, the position, and the industry, you can make a strong impression on the interviewer and show that you are a serious candidate. Here are some tips to help you ace your interview:

1. Research Preparation

Before your interview, be sure to do your research on both the company and the specific position you’re applying for. Learn about the company’s culture, values, and business goals. This will help you understand the company’s needs and how your skills and experience can contribute to their success.

- Visit the company’s website to learn about their products, services, and culture.

- Read industry publications to stay up-to-date on the latest trends and technologies.

- Network with people in the industry to learn about the company and the position.

2. Practice and Answer Effectively

Once you have researched the company and the position, it’s time to practice answering interview questions. This will help you feel more confident and prepared during the interview. Some common interview questions for Polishing Machine Operators include:

- Tell me about your experience operating polishing machines.

- How do you ensure that the materials you are polishing meet quality standards?

- What are some of the challenges you have faced as a Polishing Machine Operator?

- How do you stay up-to-date on the latest trends and technologies in the industry?

3. Highlight Relevant Skills and Experience

During the interview, be sure to highlight your relevant skills and experience. This includes your technical skills, as well as your soft skills, such as communication and teamwork. For example, you could talk about how your experience operating polishing machines has given you the skills necessary to achieve a smooth and shiny finish on surfaces, or how your ability to work independently and as part of a team has helped you to meet deadlines and exceed expectations.

4. Prepare Questions for Interviewer

At the end of the interview, you will have the opportunity to ask the interviewer questions. This is a great way to show your interest in the position and the company, as well as to learn more about the opportunity. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the company’s goals for the next year?

- What is the company culture like?

- What are the opportunities for advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Polishing Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.