Are you gearing up for a career in Polymer Tester? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Polymer Tester and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

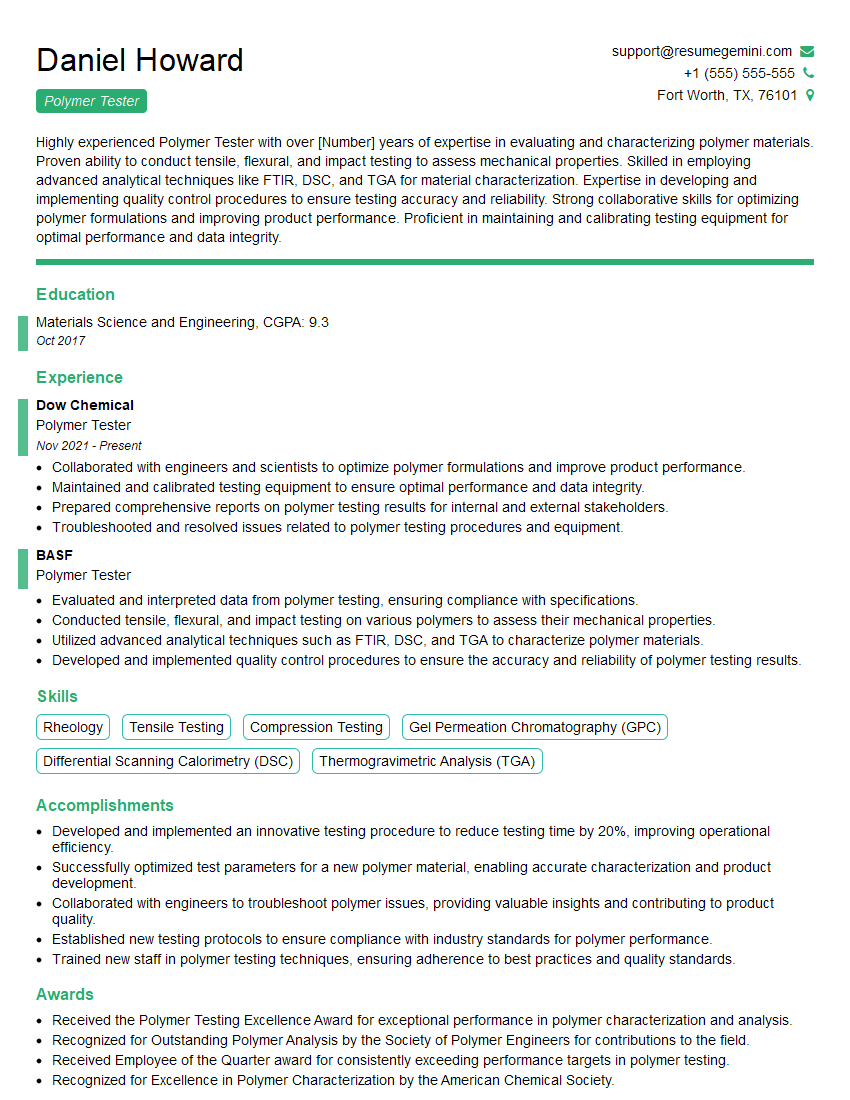

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Polymer Tester

1. Describe the process of conducting a tensile test on a polymer sample.

The tensile test is a fundamental mechanical characterization technique used to determine the mechanical properties of a polymer sample under uniaxial tension.

- Sample preparation: The sample is cut into a dumbbell-shaped specimen with precise dimensions according to ASTM standards.

- Tensile testing machine: The specimen is mounted in a tensile testing machine, which applies a controlled force to stretch the sample.

- Data acquisition: The machine records the force (load) and displacement (extension) of the sample throughout the test.

- Stress-strain curve: The data is plotted as a stress-strain curve, which provides information about the sample’s tensile strength, Young’s modulus, and elongation at break.

2. Explain the significance of glass transition temperature (Tg) in polymers.

Glass Transition Temperature (Tg)

- Tg is the temperature at which a polymer undergoes a transition from a glassy to a rubbery state.

- Below Tg, the polymer is hard and brittle, while above Tg, it becomes more flexible and rubbery.

- Tg is an important property for understanding the behavior and application of polymers.

Significance of Tg

- Predicts the temperature range in which a polymer can be processed or used.

- Affects the mechanical properties of polymers, such as stiffness, strength, and toughness.

- Influences the electrical, thermal, and optical properties of polymers.

3. Discuss the role of crosslinking in polymer networks.

Crosslinking is a chemical process that creates covalent bonds between polymer chains, forming a network structure.

- Increased strength and stiffness: Crosslinking restricts the movement of polymer chains, resulting in higher strength and stiffness.

- Improved thermal stability: Crosslinked polymers have higher melting temperatures and are less likely to deform under heat.

- Reduced solubility: Crosslinking reduces the solubility of polymers in solvents, making them more resistant to degradation.

- Tailoring properties: The degree of crosslinking can be controlled to achieve specific properties, such as elasticity, toughness, and thermal stability.

4. Explain the concept of polymer blends and their advantages.

Polymer blends are mixtures of two or more polymers with different properties, combined to create a material with tailored properties.

- Enhanced properties: Blends can combine the desirable properties of different polymers, such as strength, flexibility, and temperature resistance.

- Cost optimization: Blending can reduce the cost of a material by using less expensive polymers while maintaining desired properties.

- Tailored performance: The composition and ratio of polymers in a blend can be optimized to achieve specific performance requirements.

- New materials: Blending can lead to the development of novel materials with unique properties not achievable with single polymers.

5. Describe the different types of polymer degradation mechanisms and their impact on material properties.

- Thermal degradation: Caused by exposure to high temperatures, leading to chain scission, crosslinking, and formation of volatile products.

- Oxidative degradation: Reaction with oxygen, resulting in chain scission, formation of free radicals, and loss of mechanical strength.

- Photodegradation: Caused by ultraviolet radiation, breaking down polymer chains and leading to discoloration, embrittlement, and reduced strength.

- Biological degradation: Attack by microorganisms, causing chain scission and loss of material properties.

6. Explain the importance of quality control in polymer testing and its impact on product safety and reliability.

Quality control ensures the accuracy and reliability of polymer testing results, which are critical for:

- Product safety: Verifying that polymers meet safety specifications and regulations, ensuring they are safe for intended use.

- Product reliability: Guaranteeing that polymers perform consistently and meet performance requirements, preventing product failures.

- Process optimization: Identifying areas for improvement in manufacturing processes to enhance product quality.

- Customer satisfaction: Providing assurance that products meet customer expectations and specifications.

7. Discuss the role of polymer characterization techniques in the development of new materials.

- Identification and analysis: Techniques like spectroscopy and chromatography identify the composition, structure, and properties of new polymers.

- Property evaluation: Mechanical, thermal, and electrical characterization methods assess the performance and application potential of new materials.

- Optimization: Characterization data guides the modification and improvement of polymer structures to achieve desired properties.

- Quality control: Characterization techniques ensure the consistency and quality of new polymers during production and application.

8. Explain the importance of understanding the viscoelastic behavior of polymers in real-world applications.

Viscoelasticity describes the time-dependent and temperature-dependent behavior of polymers, which is crucial in applications such as:

- Vibration damping: Viscoelastic polymers absorb and dissipate energy from vibrations, reducing noise and improving comfort in vehicles and appliances.

- Shock absorption: Viscoelastic materials cushion and protect against impact forces, enhancing safety in sports equipment and protective gear.

- Adhesives: Viscoelastic adhesives form strong bonds with surfaces, providing flexibility and durability under changing conditions.

- Packaging: Viscoelastic polymers ensure the integrity and protection of packaged goods by absorbing and dissipating external forces.

9. Describe the challenges associated with testing and characterizing biodegradable polymers.

- Biodegradability assessment: Determining the rate and extent of polymer degradation in specific environments can be complex and time-consuming.

- Environmental variability: Biodegradation rates are influenced by factors such as temperature, pH, and microbial activity, making testing conditions crucial.

- Compostability validation: Ensuring that biodegradable polymers meet industrial and home composting standards requires specific testing protocols.

- End-of-life impact: Evaluating the environmental impact of biodegradable polymers after their useful life is essential to ensure sustainability.

10. Discuss the ethical considerations in the development and testing of polymeric materials.

- Environmental impact: Assessing the sustainability and end-of-life disposal of polymeric materials to minimize environmental pollution.

- Health and safety: Ensuring that polymers are safe for human health and do not pose risks to workers or consumers.

- Data integrity and transparency: Reporting testing results accurately and avoiding bias to maintain public trust in scientific research.

- Responsible innovation: Considering the potential societal and environmental consequences of new polymeric materials before their commercialization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Polymer Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Polymer Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Polymer Tester is vital professional responsible for ensuring that polymers meet the required specifications for their intended use. Their key job responsibilities include:

1. Material Testing and Evaluation

Conducting physical and mechanical tests on polymer materials, such as tensile testing, compression testing, and impact resistance testing.

- Analysing test results to determine material properties, such as strength, modulus, and elongation.

- Interpreting test data to identify potential issues or areas for improvement.

2. Quality Control and Assurance

Ensuring that polymers meet the specified quality standards and regulatory requirements.

- Developing and implementing quality control procedures to monitor and maintain product quality.

- Performing audits and inspections to verify compliance with standards and regulations.

3. Research and Development Support

Collaborating with research and development teams to develop and test new polymers and improve existing ones.

- Designing and conducting experiments to evaluate new materials or processes.

- Providing technical insights and support to researchers and engineers.

4. Customer Support and Technical Assistance

Providing technical guidance and support to customers and stakeholders.

- Answering inquiries and resolving technical issues related to polymer materials.

- Developing technical documentation, such as test reports and user manuals.

Interview Tips

To effectively prepare for an interview for a Polymer Tester position, it is essential to showcase your skills and experience in the following areas:

1. Polymer Materials Knowledge

Demonstrate a thorough understanding of different types of polymers, their properties, and applications.

- Familiarity with common test methods and standards for polymer materials.

2. Materials Testing Techniques

Highlight your proficiency in various materials testing techniques and equipment.

- Expertise in tensile testing, compression testing, and impact resistance testing.

- Strong analytical skills to interpret test data and identify trends and patterns.

3. Quality Control and Management

Emphasise your experience in developing and implementing quality control procedures.

- Knowledge of industry standards and regulations related to polymer products.

- Ability to conduct audits and inspections to ensure compliance.

4. Problem-Solving and Critical Thinking

Demonstrate your ability to analyse data, troubleshoot issues, and identify solutions.

- Provide examples of how you have used critical thinking and problem-solving skills to resolve technical challenges.

- Highlight your ability to collaborate and communicate effectively with engineers, researchers, and customers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Polymer Tester interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.