Are you gearing up for a career in Polymerization Kettle Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Polymerization Kettle Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

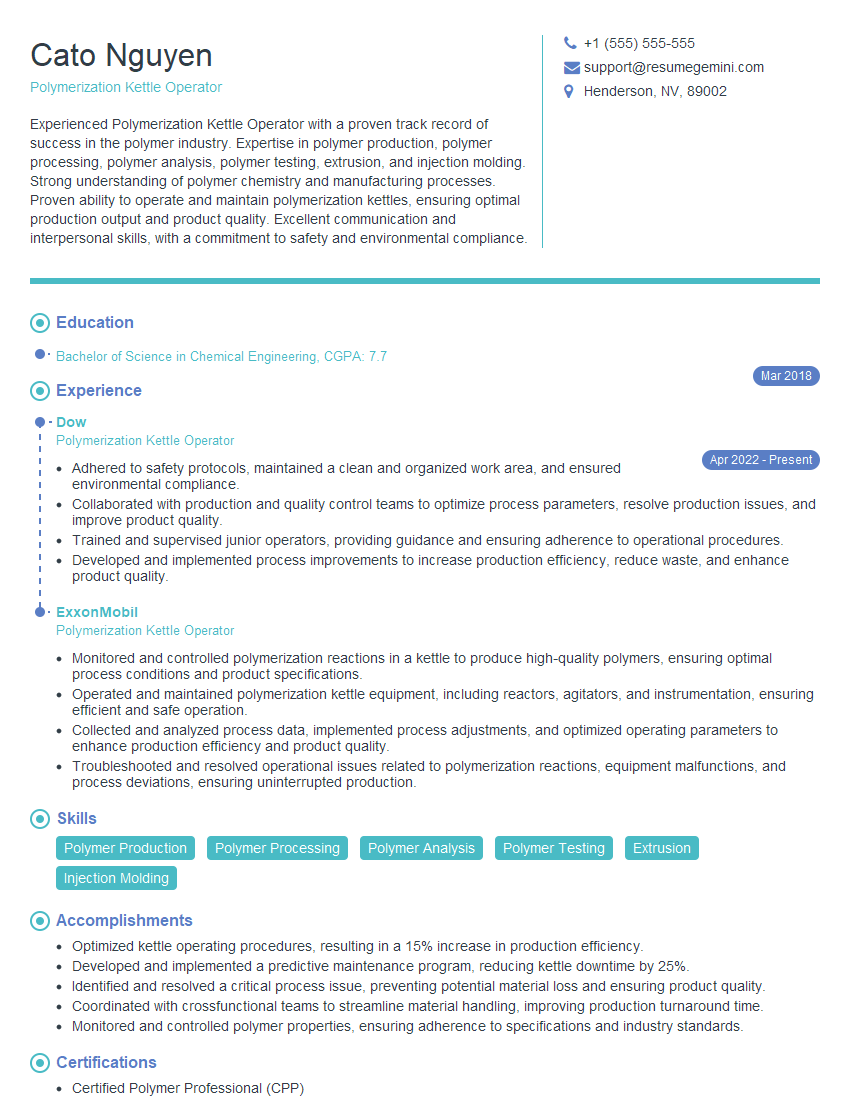

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Polymerization Kettle Operator

1. What are the key safety procedures you follow when operating a polymerization kettle?

- Wear appropriate personal protective equipment (PPE), including coveralls, safety glasses, gloves, and a hard hat.

- Inspect the kettle and all equipment for any damage or leaks prior to operation.

- Ensure the area around the kettle is clean and free of any tripping hazards.

- Follow the established safety protocols for the operation of the kettle, including the use of interlocks and alarms.

- Monitor the kettle closely during operation and take appropriate action in the event of any unusual conditions.

- Immediately report any accidents or incidents to the supervisor.

2. Describe the steps involved in preparing a polymerization kettle for operation.

- Inspect the kettle and ancillary equipment for any visible damage or leaks.

- Connect the kettle to the appropriate utilities, including water, steam, and nitrogen.

- Charge the kettle with the required amount of monomers, catalysts, and other additives.

- Heat the kettle to the desired reaction temperature and hold for the required reaction time.

- Cool the kettle to the desired temperature and discharge the product.

- Clean and inspect the kettle and ancillary equipment after each operation.

3. What types of problems can occur during polymerization and how do you troubleshoot them?

- Gel formation: Gels can form due to high temperatures, the presence of impurities, or the use of the wrong catalyst. To troubleshoot, reduce the temperature, remove any impurities, and change the catalyst.

- Kettle fouling: Fouling can occur due to the accumulation of solids on the kettle walls. To troubleshoot, clean the kettle regularly and use anti-fouling agents.

- Product contamination: Contamination can occur due to leaks in the system or the use of contaminated raw materials. To troubleshoot, identify the source of the contamination and take corrective action.

- Equipment failure: Equipment failures can occur due to mechanical problems or power outages. To troubleshoot, identify the failed component and repair or replace it.

4. How do you maintain and calibrate the equipment used in a polymerization kettle?

- Follow the manufacturer’s instructions for maintenance and calibration.

- Inspect the equipment regularly for any signs of wear or damage.

- Calibrate the equipment using certified standards.

- Keep a maintenance log to document all maintenance and calibration activities.

5. What are the different types of polymerization reactions and which type is used in the kettles you operate?

- Addition polymerization: This type of polymerization involves the addition of monomers to a growing polymer chain. It is used to produce polymers such as polyethylene and polypropylene.

- Condensation polymerization: This type of polymerization involves the formation of a polymer chain by the condensation of two or more monomers. It is used to produce polymers such as nylon and polyester.

- Free radical polymerization: This type of polymerization involves the initiation of a free radical chain reaction, which leads to the formation of a polymer chain. It is used to produce polymers such as polystyrene and polyvinyl chloride.

6. How do you handle and dispose of hazardous materials used in the polymerization process?

- Wear appropriate personal protective equipment (PPE) when handling hazardous materials.

- Follow the manufacturer’s instructions for handling and disposal of hazardous materials.

- Dispose of hazardous materials in accordance with local regulations.

7. What is the importance of quality control in the operation of a polymerization kettle?

- Quality control is essential to ensure the production of high-quality polymers.

- Quality control measures include monitoring the reaction conditions, testing the product, and maintaining the equipment.

- By implementing quality control measures, manufacturers can ensure that their products meet customer specifications and regulatory requirements.

8. What are the environmental regulations that apply to the operation of a polymerization kettle?

- The environmental regulations that apply to the operation of a polymerization kettle vary depending on the location of the facility.

- Common regulations include those related to air emissions, water discharge, and waste disposal.

- Manufacturers must comply with all applicable environmental regulations to protect the environment and the health of the public.

9. What are the safety hazards associated with the operation of a polymerization kettle?

- Fire and explosion: Polymerization reactions can generate heat and flammable gases, which can lead to fires and explosions.

- Chemical exposure: Operators can be exposed to hazardous chemicals during the operation of a polymerization kettle.

- Mechanical hazards: The equipment used in a polymerization kettle can pose mechanical hazards, such as rotating machinery and high-pressure systems.

10. What is your understanding of the role of a Polymerization Kettle Operator in a chemical plant?

- The Polymerization Kettle Operator is responsible for the safe and efficient operation of the polymerization kettle.

- The Operator monitors the reaction conditions, controls the flow of materials, and ensures the quality of the product.

- The Operator also performs maintenance and troubleshooting on the kettle and ancillary equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Polymerization Kettle Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Polymerization Kettle Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Polymerization Kettle Operators play a crucial role in the production of polymers, a key component of various products ranging from plastics to pharmaceuticals. Their primary responsibilities entail:

1. Kettle Operation and Control

Operating and controlling polymerization kettles to produce the desired polymer grade.

- Monitoring and adjusting process variables (e.g., temperature, pressure, feed rates) to optimize polymer production.

- Ensuring proper operation of equipment, including kettles, pumps, and instrumentation.

2. Polymer Quality Control

Maintaining product quality by monitoring and analyzing polymer properties.

- Testing polymer samples to determine characteristics such as molecular weight, particle size, and purity.

- Making adjustments to the process to meet quality specifications.

3. Process Improvement and Troubleshooting

Identifying and addressing process inefficiencies and problems.

- Evaluating process data to identify areas for improvement.

- Troubleshooting equipment malfunctions and devising solutions to maintain production.

4. Safety and Environmental Compliance

Adhering to safety protocols and environmental regulations.

- Following established safety procedures and using appropriate personal protective equipment.

- Monitoring environmental emissions and ensuring compliance with regulations.

Interview Tips

Preparing thoroughly for an interview can significantly enhance your chances of success. Here are some tips to help you ace your Polymerization Kettle Operator interview:

1. Research the Company and Industry

Demonstrate your enthusiasm for the position by researching the company, its products, and the polymer industry. This knowledge will allow you to ask informed questions and highlight your understanding of the market.

- Visit the company website to learn about their history, operations, and future plans.

- Read industry publications and news articles to stay updated on the latest trends and technologies.

2. Highlight Relevant Skills and Experience

Carefully review the job description and identify the key responsibilities and qualifications required. Emphasize your experience and skills that directly align with these requirements.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Prepare examples of how you have successfully handled challenges and solved problems in previous roles.

3. Be Enthusiastic and Confident

Your attitude and demeanor can significantly influence the interviewer’s perception of you. Maintain a positive and enthusiastic attitude throughout the interview, and be confident in your abilities.

- Make eye contact, speak clearly, and articulate your answers succinctly.

- Be prepared to discuss your strengths and weaknesses, and how they relate to the job requirements.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. Prepare a few questions that will help you gain insights into the company culture, team dynamics, and career growth opportunities.

- For example, you could inquire about the company’s commitment to sustainability or the potential for professional development within the organization.

- Remember to keep your questions concise and respectful.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Polymerization Kettle Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.