Feeling lost in a sea of interview questions? Landed that dream interview for Polymerization Oven Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Polymerization Oven Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

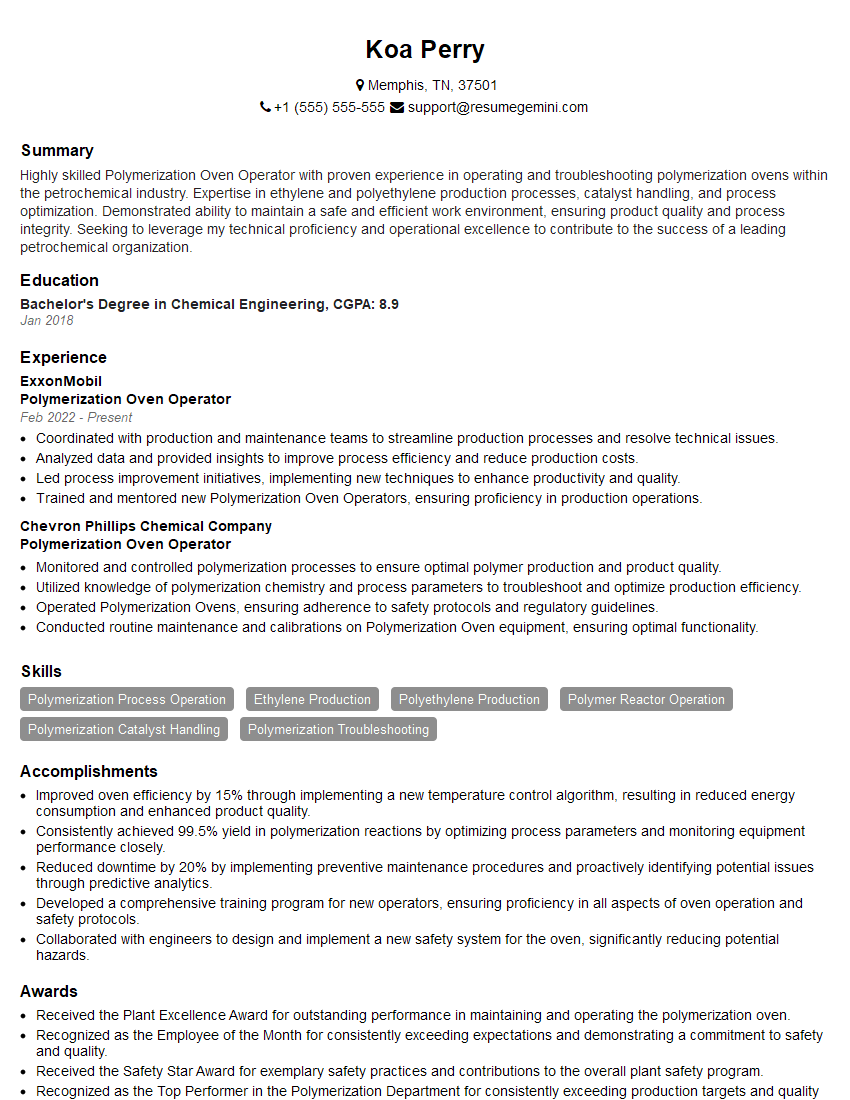

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Polymerization Oven Operator

1. What is the principle of Polymerization Oven?

The Polymerization Oven operates on the principle of thermal polymerization, where monomers are heated to a specific temperature to initiate and sustain the polymerization reaction. The oven provides a controlled environment, maintaining precise temperature, pressure, and agitation to facilitate the polymerization process.

2. Describe the safety precautions you observe while operating a Polymerization Oven.

соблюдение личной гигиены

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat.

- Maintain a clean and organized work area to minimize the risk of contamination.

Определение опасности

- Be aware of the potential hazards associated with the materials being used, such as flammability, toxicity, and reactivity.

- Follow established safety protocols and procedures for handling and storing hazardous materials.

Управление рисками

- Use proper ventilation to control exposure to fumes and vapors.

- Ground all equipment to prevent static discharge and potential explosions.

3. How do you ensure the proper functioning of the Polymerization Oven?

To ensure proper functioning of the Polymerization Oven, I perform regular maintenance and calibration. This includes:

- Checking the accuracy of temperature sensors and controllers.

- Inspecting and calibrating pressure gauges and valves.

- Monitoring the performance of agitators and ensuring they are operating smoothly.

- Regularly cleaning and maintaining the oven chamber to prevent contamination and ensure efficient heat transfer.

4. What are the different types of polymers that can be produced using a Polymerization Oven?

Various types of polymers can be produced using a Polymerization Oven, including:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Polystyrene (PS)

- Polyethylene terephthalate (PET)

- Polycarbonate (PC)

The specific type of polymer produced depends on the monomers used, the polymerization conditions, and the desired properties of the final product.

5. How do you optimize the polymerization process to achieve desired polymer properties?

To optimize the polymerization process and achieve desired polymer properties, I consider several factors, including:

- Selection of appropriate monomers and catalysts.

- Control of temperature, pressure, and agitation during the reaction.

- Monitoring the reaction progress and making adjustments as needed.

- Understanding the relationship between polymerization conditions and polymer properties.

6. What troubleshooting steps do you take when the Polymerization Oven malfunctions?

In the event of a Polymerization Oven malfunction, I follow a systematic troubleshooting process:

- Identify the problem by observing symptoms and error messages.

- Refer to the oven’s maintenance manual and technical specifications.

- Check for any obvious issues, such as loose connections or faulty components.

- Perform diagnostic tests and measurements to pinpoint the source of the problem.

- Take appropriate corrective actions, such as replacing faulty parts or adjusting settings.

7. How do you ensure the quality of the finished polymer product?

To ensure the quality of the finished polymer product, I employ various quality control measures:

- Monitoring the polymerization process and recording process parameters.

- Conducting regular testing and analysis of the polymer properties.

- Comparing the results to established specifications and standards.

- Maintaining documentation of all quality control procedures and results.

8. What are the industry best practices for Polymerization Oven operation?

Adhering to industry best practices is crucial for safe and efficient Polymerization Oven operation. These include:

- Following established operating procedures and safety guidelines.

- Using appropriate materials and equipment for the specific polymerization process.

- Maintaining a clean and organized work environment.

- Regularly calibrating and maintaining the oven and its components.

- Documenting all operations and maintenance activities.

9. How do you stay updated on the latest advancements in Polymerization Oven technology?

To stay abreast of the latest advancements in Polymerization Oven technology, I engage in continuous learning and development:

- Attending industry conferences and exhibitions.

- Reading technical journals and publications.

- Participating in online forums and discussion groups.

- Seeking training and certification opportunities.

10. Why are you interested in this Polymerization Oven Operator position?

I am eager to join your organization as a Polymerization Oven Operator because I am passionate about polymer science and technology. I am confident that my skills and experience in operating and maintaining polymerization ovens, combined with my commitment to safety and quality, will make me a valuable asset to your team. I am eager to contribute to the success of your polymer production operations and am excited about the opportunity to learn and grow within your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Polymerization Oven Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Polymerization Oven Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Polymerization Oven Operator is responsible for the safe and efficient operation of the polymerization oven, a critical piece of equipment in the production of polymers. The primary objective of this role is to ensure that the polymerization process runs smoothly and according to specifications.

1. Oven Operation and Maintenance

The operator is accountable for the proper functioning of the polymerization oven and its associated equipment. Their duties include:

- Monitoring and controlling the temperature, pressure, and other process parameters of the oven to ensure optimal polymerization conditions

- Loading and unloading materials into and out of the oven, ensuring proper handling and inventory management

- Performing routine maintenance and cleaning of the oven and its components to maintain equipment efficiency and safety

2. Process Monitoring and Control

The operator closely monitors the polymerization process to ensure it meets quality standards. Their responsibilities include:

- Recording and analyzing process data, identifying any deviations from specifications

- Adjusting process parameters as needed to optimize polymerization outcomes

- Communicating any process issues or deviations to supervisors or relevant personnel for timely resolution

3. Safety Compliance and Emergency Preparedness

The operator is responsible for maintaining a safe work environment and adhering to all safety regulations. Their duties include:

- Following established safety protocols and procedures to prevent accidents and injuries

- Identifying and reporting any potential hazards or unsafe conditions

- Responding appropriately to emergencies, following established protocols and evacuation procedures

4. Production Support and Optimization

The operator plays a role in supporting production efficiency and optimization. Their responsibilities include:

- Collaborating with other team members to troubleshoot process issues and improve production yields

- Participating in process improvement initiatives, providing valuable insights from their operational experience

- Adhering to quality control standards, ensuring the production of high-quality polymer products

Interview Tips

To ace the interview for the Polymerization Oven Operator position, candidates should prepare thoroughly and showcase their relevant skills and experience.

1. Research the Company and Industry

- Learn about the company’s history, products, and market position

- Understand the role of polymerization in the industry and its applications

2. Highlight Relevant Experience and Skills

- Emphasize experience in operating polymerization ovens or similar equipment

- Describe your understanding of the polymerization process and your ability to monitor and control it

- Showcase your ability to follow safety protocols and respond to emergencies effectively

3. Quantify Your Accomplishments

- Use specific examples and data to demonstrate your contributions in previous roles

- Highlight your ability to improve production efficiency, reduce downtime, or enhance product quality

4. Prepare for Technical Questions

- Review principles of polymerization, including types of reactions, catalysts, and process variables

- Be familiar with the equipment used in the polymerization process, such as ovens, reactors, and control systems

- Anticipate questions related to safety protocols, emergency procedures, and troubleshooting techniques

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Polymerization Oven Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.