Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Polystyrene Molding Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

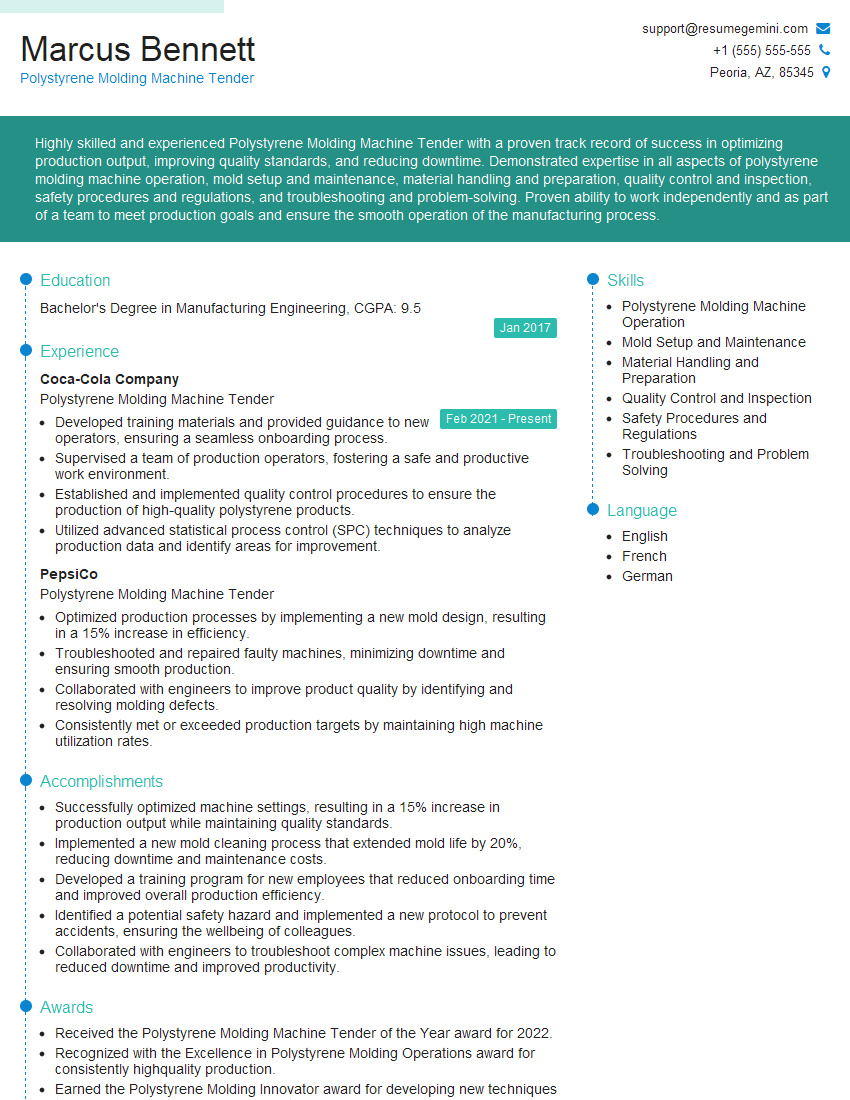

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Polystyrene Molding Machine Tender

1. Explain the process of polystyrene molding using a polystyrene molding machine.

The polystyrene molding process involves the following steps:

- Pre-expansion: Polystyrene beads are pre-expanded using steam to create a lightweight and porous material.

- Molding: The pre-expanded beads are placed into a mold and heated to melt and fuse them together.

- Cooling: The mold is cooled to solidify the polystyrene and create the desired shape.

- Demolding: The molded polystyrene is ejected from the mold.

2. Describe the key components of a polystyrene molding machine and their functions.

- Pre-expander: Expands the polystyrene beads using steam.

- Mold: Forms the shape of the molded polystyrene.

- Heater: Melts and fuses the polystyrene beads.

- Cooling system: Cools the mold to solidify the polystyrene.

- Ejection system: Ejects the molded polystyrene from the mold.

3. What are the different types of polystyrene molding machines available?

- Steam chest molding machines: Use steam to pre-expand the beads.

- Vacuum molding machines: Use a vacuum to draw the pre-expanded beads into the mold cavity.

- Pressure molding machines: Apply pressure to the pre-expanded beads to form the desired shape.

4. What are the factors to consider when selecting the appropriate polystyrene molding machine?

- Type of polystyrene product: Different products require different molding techniques.

- Production volume: The required production output will determine the size and capacity of the machine.

- Available space: The machine must fit into the available production area.

- Budget: The cost of the machine must align with financial constraints.

5. How do you maintain and troubleshoot a polystyrene molding machine?

6. Describe the quality control procedures for polystyrene molded products.

- Visual inspection: Check for surface defects, shape accuracy, and dimensions.

- Dimensional measurements: Verify that the products meet the specified dimensions.

- Strength testing: Test the products’ ability to withstand stress and load.

- Density testing: Ensure that the products meet the required density specifications.

7. What safety precautions should be taken when operating a polystyrene molding machine?

- Wear protective gear: Safety glasses, gloves, and earplugs.

- Follow operating procedures: Adhere to established safety protocols.

- Avoid contact with hot surfaces: Prevent burns and injuries.

- Handle chemicals safely: Use appropriate ventilation and protective measures.

8. How do you optimize the performance of a polystyrene molding machine?

- Calibrate the machine: Ensure accuracy and precision in measurements and operations.

- Optimize the molding conditions: Adjust temperature, pressure, and cycle time for optimal results.

- Monitor the machine’s performance: Track key metrics to identify areas for improvement.

- Implement continuous improvement: Identify and implement ways to increase efficiency and reduce waste.

9. What are the common challenges faced when operating a polystyrene molding machine and how do you overcome them?

Challenges:

- Sticking of polystyrene to the mold: Use mold release agents and adjust molding conditions.

- Dimensional variations: Calibrate the machine and optimize the molding parameters.

- Defects in the molded products: Identify the root cause and implement corrective actions.

10. How do you stay up-to-date with the latest advances in polystyrene molding technology?

- Attend industry events and conferences: Network with experts and learn about new developments.

- Read technical publications and journals: Stay informed about research and advancements.

- Collaborate with suppliers and manufacturers: Gain insights from industry professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Polystyrene Molding Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Polystyrene Molding Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Polystyrene Molding Machine Tenders work in manufacturing facilities to produce polystyrene products, such as plastic cups, plates, and containers. Their primary responsibilities include:

1. Machine Setup and Operation

Setting up and operating polystyrene molding machines according to specifications, ensuring optimal production output.

- Loading raw materials into the machine.

- Adjusting machine settings for temperature, pressure, and cycle time.

- Monitoring the molding process to ensure product quality.

2. Product Inspection and Quality Control

Inspecting molded products for defects, such as cracks, voids, or discoloration. Maintaining quality standards by adhering to established procedures.

- Visually examining products for flaws.

- Using gauges or other tools to measure dimensions and tolerances.

- Identifying and isolating defective products.

3. Machine Maintenance and Troubleshooting

Performing routine maintenance on polystyrene molding machines, including cleaning, lubrication, and minor repairs. Troubleshooting and resolving any operational issues that arise.

- Cleaning machine components and work areas.

- Replacing worn or damaged parts.

- Diagnosing and fixing malfunctions.

4. Production Planning and Scheduling

Assisting in production planning and scheduling to ensure efficient machine utilization and meet customer orders. Monitoring production rates and identifying areas for improvement.

- Reviewing production orders and schedules.

- Communicating with supervisors to adjust machine settings and allocate resources.

- Analyzing production data to optimize machine performance.

Interview Tips

Preparing for an interview as a Polystyrene Molding Machine Tender requires a combination of technical knowledge and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and industry reputation. Review the job description thoroughly to understand the specific responsibilities and qualifications required.

- Visit the company website and social media pages.

- Read industry news and articles to gain insights into current trends.

- Prepare questions related to the company’s business and the role’s contribution.

2. Highlight Relevant Experience and Skills

Showcase your experience operating and maintaining polystyrene molding machines. Emphasize your ability to identify and resolve production issues, ensure product quality, and work effectively in a manufacturing environment.

- Quantify your accomplishments with specific metrics, such as increased production output or reduced downtime.

- Provide examples of your troubleshooting abilities and how you resolved complex problems.

- Discuss your understanding of polystyrene molding processes and quality control standards.

3. Practice Your Behavioral Answers

Behavioral interview questions focus on your past experiences and how you handled specific situations. Prepare examples that demonstrate your problem-solving skills, teamwork ability, and attention to detail.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Choose experiences that align with the job requirements and company values.

- Practice delivering your answers concisely and confidently.

4. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions that demonstrate your curiosity about the company, the role, and the opportunity for career growth.

- Ask about the company’s future plans and growth prospects.

- Inquire about opportunities for training and professional development.

- Ask about the company’s safety protocols and environmental initiatives.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Polystyrene Molding Machine Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Polystyrene Molding Machine Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.