Are you gearing up for an interview for a Porcelain Enamel Laborer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Porcelain Enamel Laborer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

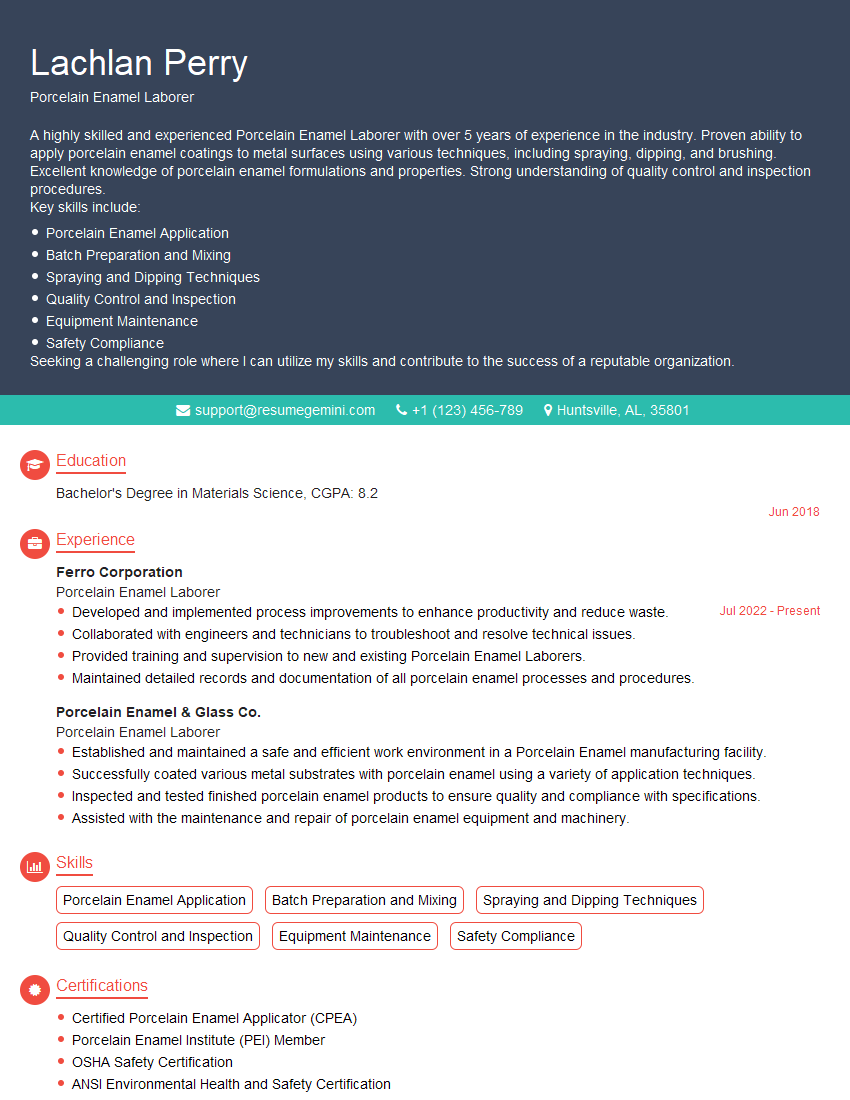

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Porcelain Enamel Laborer

1. Explain the basic steps involved in porcelain enameling?

- Surface Preparation: Cleaning and preparing the metal surface to ensure proper adhesion.

- Slurry Application: Mixing porcelain enamel powder with water to form a slurry and applying it to the surface.

- Firing: Heating the coated metal in a kiln at high temperatures (800-1000°C) to fuse the enamel to the surface.

- Cooling: Allowing the fired enamel to cool slowly to minimize thermal stress.

- Inspection: Examining the finished product for defects or imperfections.

2. Describe the different types of porcelain enamel slurries?

Wet Slurries

- Contain high water content for dipping or curtain coating.

- Typically used for large, flat surfaces.

Dry Slurries

- Have lower water content and are applied using spray or electrostatic methods.

- Suitable for intricate shapes or hard-to-reach areas.

3. What are the key factors that affect the quality of porcelain enamel coatings?

- Slurry Composition: Correct ratios of raw materials and consistent mixing.

- Surface Preparation: Proper cleaning and grit blasting for optimal adhesion.

- Firing Conditions: Accurate temperature and timing control during firing.

- Cooling Rate: Gradual cooling to prevent thermal stress cracking.

4. How do you troubleshoot common defects in porcelain enamel coatings?

- Blisters: Identifying trapped air or moisture and adjusting slurry consistency.

- Cracks: Checking firing temperatures and cooling rates, or surface preparation issues.

- Discoloration: Analyzing raw material impurities or firing atmosphere irregularities.

- Adhesion Problems: Examining surface preparation techniques and slurry compatibility.

5. Explain the role of metal oxides in porcelain enamel formulations?

- Fluxing Agents: Oxides like borax and silica lower the melting point of the enamel.

- Opacifiers: Oxides such as titanium dioxide and zirconium silicate create whiteness and opacity.

- Coloring Agents: Metal oxides like iron, cobalt, and manganese provide color to the enamel.

6. Describe the different methods used to apply porcelain enamel coatings?

- Dipping: Submerging the metal object into a slurry tank.

- Curtain Coating: Flowing the slurry over the metal surface through a curtain.

- Spraying: Using compressed air to atomize the slurry and apply it to the surface.

- Electrostatic Spraying: Applying a charge to the slurry and the metal surface, resulting in enhanced adhesion.

7. How do you ensure the safety of porcelain enamel operations?

- Proper Ventilation: Adequate ventilation to prevent exposure to fumes and dust.

- Protective Gear: Wearing respirators, gloves, and safety glasses for protection.

- Kiln Safety: Following proper kiln operation procedures and ensuring kiln integrity.

- Slurry Handling: Safe and proper storage, mixing, and disposal of porcelain enamel slurries.

8. Explain the importance of quality control in porcelain enameling?

- Product Consistency: Ensuring uniform and defect-free enamel coatings.

- Customer Satisfaction: Meeting customer specifications and producing high-quality products.

- Cost Efficiency: Identifying and minimizing defects, reducing rework and scrap.

- Reputation: Maintaining a positive reputation for reliability and quality.

9. Describe the role of an enamel laboratory in the porcelain enameling process?

- Slurry Development: Formulating and testing porcelain enamel slurries for optimal performance.

- Testing and Analysis: Conducting tests on enamel coatings for adhesion, color, and other properties.

- Problem Solving: Troubleshooting and providing solutions to enamel-related issues in production.

- Research and Innovation: Developing new enamel formulations and improving existing processes.

10. What are the recent trends and advancements in the porcelain enameling industry?

- Automation: Increasing use of automated systems for slurry application and firing.

- Digitalization: Implementation of digital tools for quality control and process monitoring.

- Sustainable Enamels: Development of eco-friendly porcelain enamel formulations with reduced environmental impact.

- New Applications: Expansion of porcelain enamel applications in various industries, such as automotive, construction, and cookware.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Porcelain Enamel Laborer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Porcelain Enamel Laborer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Porcelain Enamel Laborers are responsible for a variety of tasks related to the preparation, application, and finishing of porcelain enamel coatings on metal surfaces. Their duties may include:

1. Preparing and Cleaning Metal Surfaces

Porcelain Enamel Laborers help prepare metal surfaces to ensure that the enamel will adhere properly. They may degrease, sandblast, or otherwise clean the metal to remove any impurities or contaminants.

2. Applying Porcelain Enamel Coatings

Once the metal surface is prepared, Porcelain Enamel Laborers apply the porcelain enamel coating. This can be done by spraying, dipping, or brushing the enamel onto the metal.

3. Firing the Porcelain Enamel

After the porcelain enamel has been applied, it must be fired in a kiln to cure and harden the coating. Porcelain Enamel Laborers are responsible for setting and monitoring the kiln to ensure that the enamel is fired at the correct temperature for the required amount of time.

4. Cooling and Inspecting the Porcelain Enamel

Once the porcelain enamel has been fired, it must be cooled and inspected for any defects. Porcelain Enamel Laborers are responsible for cooling the enamel and inspecting it to ensure that it meets quality standards.

5. Packing and Shipping Porcelain Enamel Products

Once the porcelain enamel products have been inspected, they must be packed and shipped. Porcelain Enamel Laborers are responsible for packing the products and ensuring that they are properly shipped to their destination.

Interview Tips

Preparing for an interview for a Porcelain Enamel Laborer position can help you make a good impression on the interviewer and increase your chances of getting the job. Here are a few tips to help you prepare:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver clear and concise responses during the interview.

3. Bring Examples of Your Work

If you have any examples of your work that you can bring to the interview, this can be a great way to show the interviewer your skills and abilities. This could include samples of your porcelain enamel work, or photos of projects you have worked on.

4. Dress Professionally

First impressions matter, so it is important to dress professionally for the interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

5. Be Confident and Enthusiastic

Confidence and enthusiasm are contagious, and they can make a big impression on the interviewer. Be confident in your abilities and show the interviewer that you are excited about the opportunity to work for their company.

Next Step:

Now that you’re armed with the knowledge of Porcelain Enamel Laborer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Porcelain Enamel Laborer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini