Are you gearing up for a career in Portable Sawyer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Portable Sawyer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

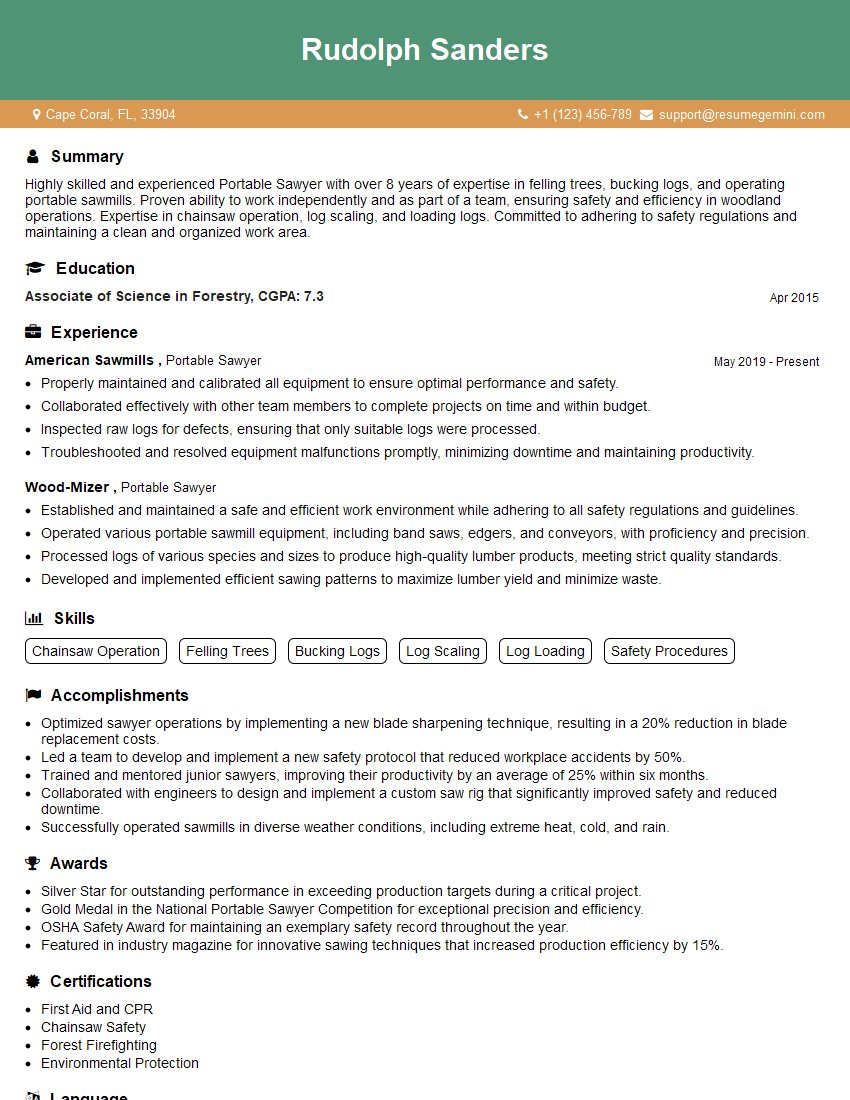

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Portable Sawyer

1. What is the best way to ensure that a portable sawmill is properly set up and used safely?

To ensure the safe setup and operation of a portable sawmill, I would follow a comprehensive approach that encompasses:

- Thorough Site Preparation: Selecting a level, stable worksite with adequate space for equipment and materials.

- Equipment Inspection: Conducting a thorough inspection of the sawmill, including its frame, blade, and safety features, to identify any potential issues or damage.

- Proper Assembly: Following the manufacturer’s instructions precisely to ensure the correct assembly of the sawmill and its components.

- Safety Gear and Protective Clothing: Utilizing appropriate personal protective equipment, such as eye and ear protection, gloves, and sturdy footwear, to minimize the risk of accidents.

- Operator Training: Ensuring that all operators are adequately trained and familiar with the sawmill’s operation, safety protocols, and emergency procedures.

2. How do you handle and maintain the blades on a portable sawmill?

Blade Handling

- Safe Handling: Using proper lifting techniques and wearing gloves when handling blades to prevent cuts or injuries.

- Secure Storage: Storing blades in a dedicated, secure location to protect them from damage or unauthorized access.

- Transportation: Transporting blades carefully, ensuring they are well-secured and protected from impacts or vibrations.

Blade Maintenance

- Regular Inspection: Routinely inspecting blades for signs of wear, damage, or dullness to ensure optimal performance and safety.

- Blade Sharpening: Sharpening blades according to the manufacturer’s recommendations using specialized equipment and techniques to maintain their cutting efficiency.

- Blade Replacement: Replacing blades promptly when they are damaged, excessively worn, or no longer meet safety standards.

3. What are the different cutting techniques used with a portable sawmill, and when would you use each technique?

- Plain Sawing: A basic technique that produces straight, flat-sawn boards with parallel faces and edges, suitable for general construction and framing.

- Quarter Sawing: A more advanced technique that results in boards with a unique grain pattern and enhanced stability, often used for flooring, furniture, and other applications where aesthetics and durability are important.

- Rift Sawing: A variation of quarter sawing that produces boards with a straight grain and reduced shrinkage, making it ideal for highly stable applications such as boatbuilding.

4. How do you optimize the yield and quality of lumber produced by a portable sawmill?

- Log Selection: Selecting logs with good quality and minimal defects to maximize the yield of usable lumber.

- Proper Sawing Techniques: Using appropriate cutting techniques and blade configurations to minimize waste and produce high-quality lumber.

- Blade Maintenance: Ensuring that blades are sharp and properly tensioned to achieve smooth, clean cuts and reduce damage to the lumber.

- Efficient Log Positioning: Optimizing log placement on the sawmill to maximize the yield of valuable lumber cuts.

- Moisture Management: Controlling the moisture content of the lumber through proper drying techniques to prevent warping, cracking, and other defects.

5. What are the common troubleshooting steps you would take if a portable sawmill is not cutting properly?

- Blade Inspection: Checking the blade for damage, dullness, or improper tension and making necessary adjustments or replacements.

- Log Positioning: Ensuring that the log is securely positioned and aligned on the sawmill bed to prevent uneven cutting or binding.

- Feed Rate Adjustment: Adjusting the feed rate to match the cutting capacity of the sawmill and the hardness of the wood being cut.

- Lubrication: Verifying that all moving parts are properly lubricated to reduce friction and prevent premature wear.

- Motor and Electrical Check: Inspecting the motor, electrical connections, and wiring for any issues that may affect the sawmill’s performance.

6. How do you ensure the accuracy and precision of cuts made with a portable sawmill?

- Proper Sawmill Setup: Leveling and stabilizing the sawmill to ensure a precise cutting surface.

- Accurate Log Measurement: Using measuring tapes or calipers to accurately determine log dimensions and optimize cutting.

- Cutting Guides: Utilizing cutting guides or jigs to assist with precision cuts, such as straight cuts or angle cuts.

- Blade Adjustment: Fine-tuning the blade alignment and tension to achieve clean, accurate cuts.

- Maintenance and Calibration: Regularly maintaining and calibrating the sawmill to ensure its accuracy and precision over time.

7. How do you manage and dispose of sawdust and wood waste produced by a portable sawmill?

- Dust Collection: Utilizing dust collection systems to capture sawdust and wood chips, reducing airborne particles and maintaining a cleaner work environment.

- Responsible Disposal: Adhering to local regulations for the disposal of sawdust and wood waste, such as composting, burning, or recycling.

- Material Reuse: Exploring opportunities to reuse sawdust and wood waste, such as using them for animal bedding, landscaping, or other applications.

- Safety Precautions: Taking necessary safety measures when handling and disposing of sawdust, including wearing masks and protective clothing.

- Environmental Awareness: Promoting sustainable practices by minimizing waste and exploring environmentally friendly disposal methods.

8. How do you maintain and calibrate a portable sawmill to ensure optimal performance and safety?

- Regular Inspection: Conducting routine inspections to identify any signs of wear, damage, or misalignment.

- Blade Maintenance: Sharpening, tensioning, and replacing blades as needed to ensure optimal cutting performance.

- Lubrication: Applying lubricants to all moving parts to reduce friction and prevent premature wear.

- Calibration: Using precision tools and techniques to calibrate the sawmill’s cutting accuracy, ensuring consistent and precise cuts.

- Safety Checks: Verifying the proper functioning of safety features, such as blade guards, emergency stop buttons, and anti-kickback mechanisms.

9. How do you assess the quality and grade of lumber produced by a portable sawmill?

- Visual Inspection: Examining the lumber for defects such as knots, cracks, warps, or other imperfections.

- Dimensional Accuracy: Measuring the lumber to ensure it meets the specified dimensions and tolerances.

- Moisture Content: Using a moisture meter to determine the moisture content of the lumber, which affects its stability and durability.

- Grain Pattern: Assessing the grain pattern and texture of the lumber to determine its suitability for specific applications.

- Industry Standards: Referring to industry grading standards to classify the lumber based on its quality and intended use.

10. How do you optimize the efficiency and productivity of a portable sawmill operation?

- Proper Log Preparation: Preparing logs by removing dirt, debris, and loose bark to enhance cutting efficiency.

- Optimized Cutting Techniques: Utilizing appropriate cutting techniques and blade configurations to maximize yield and minimize waste.

- Efficient Log Handling: Developing a system for efficient log handling, such as using log decks or conveyors, to reduce downtime.

- Regular Maintenance: Adhering to a regular maintenance schedule to ensure the sawmill is operating at peak performance.

- Operator Training: Providing comprehensive training to operators to enhance their skills and productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Portable Sawyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Portable Sawyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Portable Sawyers are responsible for operating portable sawmills to cut logs into lumber. They work in a variety of settings, including forests, sawmills, and construction sites.

1. Operate Portable Sawmills

Portable sawyers must be able to operate portable sawmills safely and efficiently. They must be able to adjust the saw blade to the correct height and angle, and they must be able to feed the logs into the saw smoothly.

- Set up and operate portable sawmills in accordance with safety regulations

- Inspect logs for defects and determine the best cutting methods

2. Maintain Equipment

Portable sawyers must be able to maintain their equipment in good working condition. They must be able to troubleshoot problems and make repairs as needed.

- Perform routine maintenance on portable sawmills, including lubrication, blade sharpening, and adjustments

- Troubleshoot and repair equipment breakdowns

3. Produce Lumber

Portable sawyers must be able to produce lumber that meets the specifications of their customers. They must be able to cut logs to the correct dimensions and they must be able to grade the lumber according to its quality.

- Cut logs into lumber of various dimensions and grades

- Inspect lumber for defects and grade it according to industry standards

4. Work Safely

Portable sawyers must be able to work safely in a variety of environments. They must be aware of the hazards of their work and they must take precautions to avoid accidents.

- Follow safety protocols and wear appropriate personal protective equipment

- Identify and mitigate potential hazards in the work environment

Interview Tips

To ace the interview, follow these preparation tips and answer the questions in a clear, concise manner, highlighting your relevant skills and experience.

1. Research the Company and Role

Before the interview, take the time to research the company and the specific Portable Sawyer role. This will give you a better understanding of the company’s culture, the job responsibilities, and the required qualifications.

- Visit the company’s website and social media pages to learn about their values and recent projects.

- Read industry news and articles to stay up-to-date on the latest trends and best practices in the field of portable sawmilling.

2. Practice Your Answers

Once you have a good understanding of the company and the role, take some time to practice your answers to common interview questions. This will help you to feel more confident and prepared during the interview.

- Prepare examples of your experience operating portable sawmills, maintaining equipment, and producing lumber.

- Be ready to discuss your safety practices and how you ensure a safe work environment.

3. Dress Professionally and Arrive on Time

First impressions matter, so be sure to dress professionally for the interview. Also, arrive on time to show that you are respectful of the interviewer’s time.

- Wear business attire that is clean and pressed.

- Arrive for the interview a few minutes early to give yourself time to relax and compose yourself.

4. Be Enthusiastic and Positive

The interview is a chance for you to sell yourself and your skills to the interviewer. Be enthusiastic about the opportunity and positive about your abilities.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently about your experience and qualifications.

- Be prepared to ask questions about the company and the role, which shows your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Portable Sawyer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!