Feeling lost in a sea of interview questions? Landed that dream interview for Pot Firer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pot Firer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

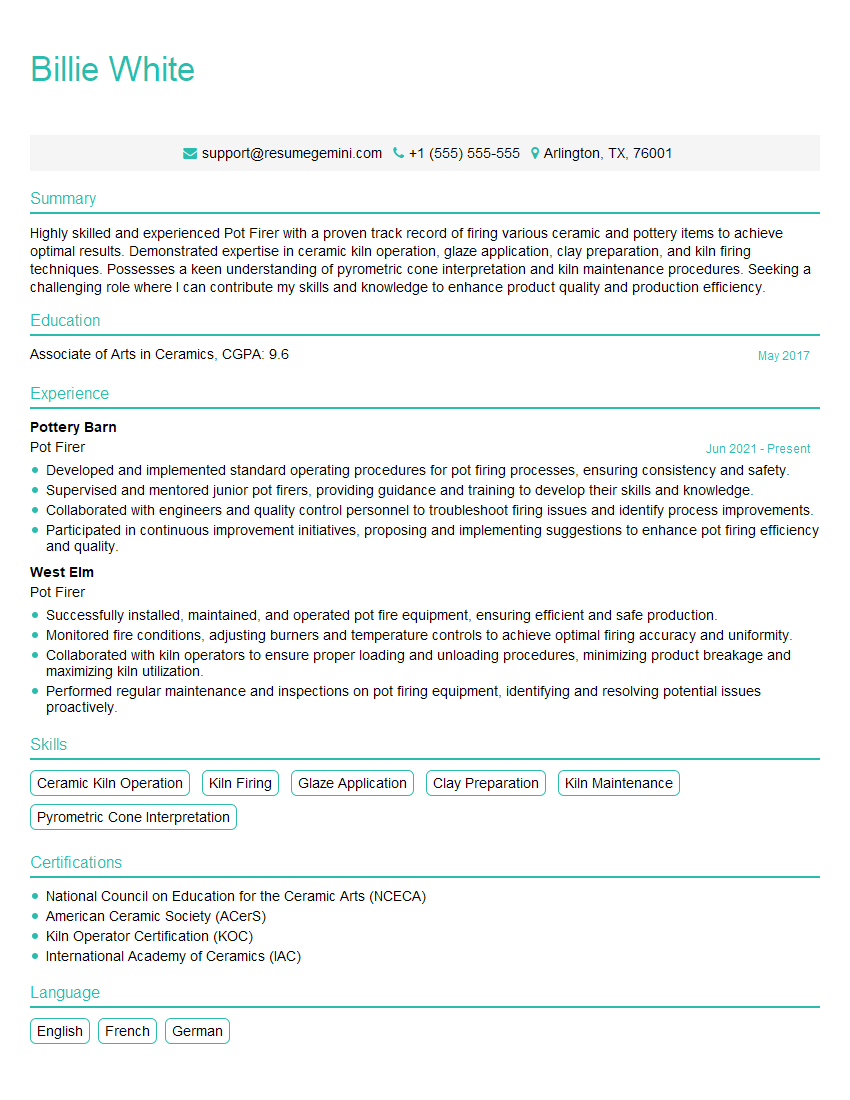

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pot Firer

1. What is the primary responsibility of a Pot Firer in a foundry?

The primary responsibility of a Pot Firer in a foundry is to operate and maintain the melting furnace or pot, ensuring that the molten metal is produced according to specifications and in a safe and efficient manner.

- Operate and monitor the melting furnace to control temperature, pressure, and metal composition

- Monitor and adjust fuel flow, oxygen levels, and other process parameters to optimize metal quality

- Inspect and maintain furnace equipment, including burners, pumps, and controls

2. What are the common types of melting furnaces used in foundries?

The common types of melting furnaces used in foundries include:

Electric Arc Furnaces (EAFs):

- Use electric arcs to melt metal

- Provide precise temperature control

- Can handle a wide range of metals and alloys

Induction Furnaces:

- Use electromagnetic induction to heat and melt metal

- Offer high efficiency and low operating costs

- Suitable for melting ferrous and non-ferrous metals

Crucible Furnaces:

- Use a crucible to hold the molten metal

- Can be heated by gas, oil, or electricity

- Ideal for melting small quantities of metal

3. What are the safety precautions that should be taken when operating a melting furnace?

Safety precautions for operating a melting furnace include:

- Wearing appropriate personal protective equipment (PPE), including heat-resistant clothing, gloves, and eye protection

- Ensuring proper ventilation to prevent exposure to fumes and gases

- Following established safety protocols for handling molten metal

- Using proper lifting techniques and equipment to move heavy objects

4. How do you determine the optimal temperature for melting different types of metals?

The optimal temperature for melting different types of metals varies depending on the metal’s composition and melting point. I use melting charts or reference tables to determine the appropriate melting temperature for each metal.

- Consider the desired metal properties and the application

- Adjust furnace settings accordingly to achieve the desired temperature

5. What are the different types of fuels used in melting furnaces and their advantages and disadvantages?

Common fuels used in melting furnaces include:

Natural Gas:

- Advantages: Widely available, relatively inexpensive

- Disadvantages: High carbon content can affect metal quality

Propane:

- Advantages: Clean-burning, high heat output

- Disadvantages: More expensive than natural gas

Electricity:

- Advantages: Precise temperature control, no emissions

- Disadvantages: Higher operating costs

Fuel Oil:

- Advantages: High energy density, low cost

- Disadvantages: Emissions, requires storage and handling

6. How do you maintain and troubleshoot melting furnaces?

To maintain and troubleshoot melting furnaces:

- Regularly inspect equipment for wear and tear

- Replace worn or damaged components promptly

- Monitor furnace performance and make adjustments as needed

- Identify potential problems and take corrective actions

- Follow manufacturer’s instructions for maintenance and troubleshooting

7. What are the common defects that can occur in metal castings and how can they be prevented?

Common defects in metal castings include:

- Gas porosity: Caused by entrapped air or gases, can be prevented by using proper degassing techniques

- Shrinkage: Caused by metal solidifying and contracting, can be prevented by using risers to feed molten metal during solidification

- Cold shuts: Occur when molten metal fails to fuse properly, can be prevented by ensuring adequate pouring temperature and mold preparation

- Cracks: Caused by internal stresses or external forces, can be prevented by using proper casting design and cooling methods

8. How do you ensure the quality of molten metal before pouring it into molds?

To ensure the quality of molten metal before pouring:

- Test the metal composition using spectroscopy or other analytical methods

- Inspect the metal visually for any impurities or defects

- Maintain proper temperature and slag control

- Use fluxing agents to remove impurities

9. What are the key factors to consider when selecting a melting furnace for a specific application?

Key factors to consider when selecting a melting furnace include:

- Type and quantity of metal to be melted

- Desired melting temperature and rate

- Available energy sources and cost

- Safety and environmental regulations

- Space and ventilation requirements

10. How do you stay up-to-date with the latest advancements in foundry technology and best practices?

To stay up-to-date with the latest advancements in foundry technology and best practices, I:

- Attend industry conferences and exhibitions

- Read technical journals and publications

- Consult with experts and manufacturers

- Participate in online forums and discussions

- Seek professional development opportunities

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pot Firer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pot Firer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Pot Firer is responsible for operating and maintaining a pot furnace, and for firing and glazing ceramic ware. This position requires a strong understanding of the pottery manufacturing process, as well as the ability to operate and maintain complex machinery. Key responsibilities include:

1. Furnace Operation

The Pot Firer is responsible for operating and maintaining the pot furnace, which is used to fire ceramic ware. The furnace must be operated at the correct temperature and atmosphere to ensure that the ware is fired properly. The Pot Firer must also be able to identify and troubleshoot any problems with the furnace.

- Operate and maintain a pot furnace

- Monitor the temperature and atmosphere of the furnace

- Troubleshoot and repair any problems with the furnace

2. Firing and Glazing

The Pot Firer is responsible for firing and glazing ceramic ware. Firing is the process of heating the ware to a high temperature in a kiln or furnace. Glazing is the process of applying a thin layer of glass to the ware. The Pot Firer must be able to fire and glaze the ware according to the manufacturer’s specifications.

- Fire and glaze ceramic ware

- Follow manufacturer’s specifications for firing and glazing

- Inspect the ware for defects after firing and glazing

3. Kiln Maintenance

The Pot Firer is responsible for maintaining the kiln or furnace. This includes cleaning the kiln, replacing the elements, and repairing any damage. The Pot Firer must be able to perform these tasks safely and efficiently.

- Clean the kiln or furnace

- Replace the elements

- Repair any damage to the kiln or furnace

4. Safety

The Pot Firer must be able to work safely in a pottery studio. This includes following all safety regulations and wearing the proper personal protective equipment. The Pot Firer must also be aware of the hazards associated with working with pottery materials.

- Follow all safety regulations

- Wear the proper personal protective equipment

- Be aware of the hazards associated with working with pottery materials

Interview Tips

The interview process can be daunting, but there are a few things you can do to prepare and increase your chances of success. Here are a few tips:

1. Research the Company and Position

Before you go on an interview, it’s important to do your research on the company and position. This will help you understand the company’s culture, goals, and values. It will also help you understand the specific requirements of the position so that you can tailor your answers to the interviewer’s questions.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company

2. Practice Your Answers

Once you have done your research, it’s time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview. You can practice with a friend, family member, or career counselor.

- Think about your strengths and weaknesses

- Prepare answers to common interview questions

- Practice your answers out loud

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment. You don’t need to wear a suit, but you should avoid wearing jeans, t-shirts, or shorts.

- Wear clean, pressed clothes

- Dress appropriately for the office environment

- Avoid wearing jeans, t-shirts, or shorts

4. Be Punctual

Punctuality shows that you respect the interviewer’s time. It’s important to arrive for your interview on time, or even a few minutes early. If you’re running late, call or email the interviewer to let them know.

- Arrive for your interview on time

- If you’re running late, call or email the interviewer

- Don’t be late!

5. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest, authentic, and enthusiastic. The interviewer will be able to tell if you’re not being genuine.

- Be honest, authentic, and enthusiastic

- Don’t try to be someone you’re not

- The interviewer will be able to tell if you’re not being genuine

6. Follow Up

After the interview, it’s important to follow up with the interviewer. This shows that you’re still interested in the position and that you appreciate their time. You can follow up by sending a thank-you note or email.

- Send a thank-you note or email

- Reiterate your interest in the position

- Thank the interviewer for their time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pot Firer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!