Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pot Liner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

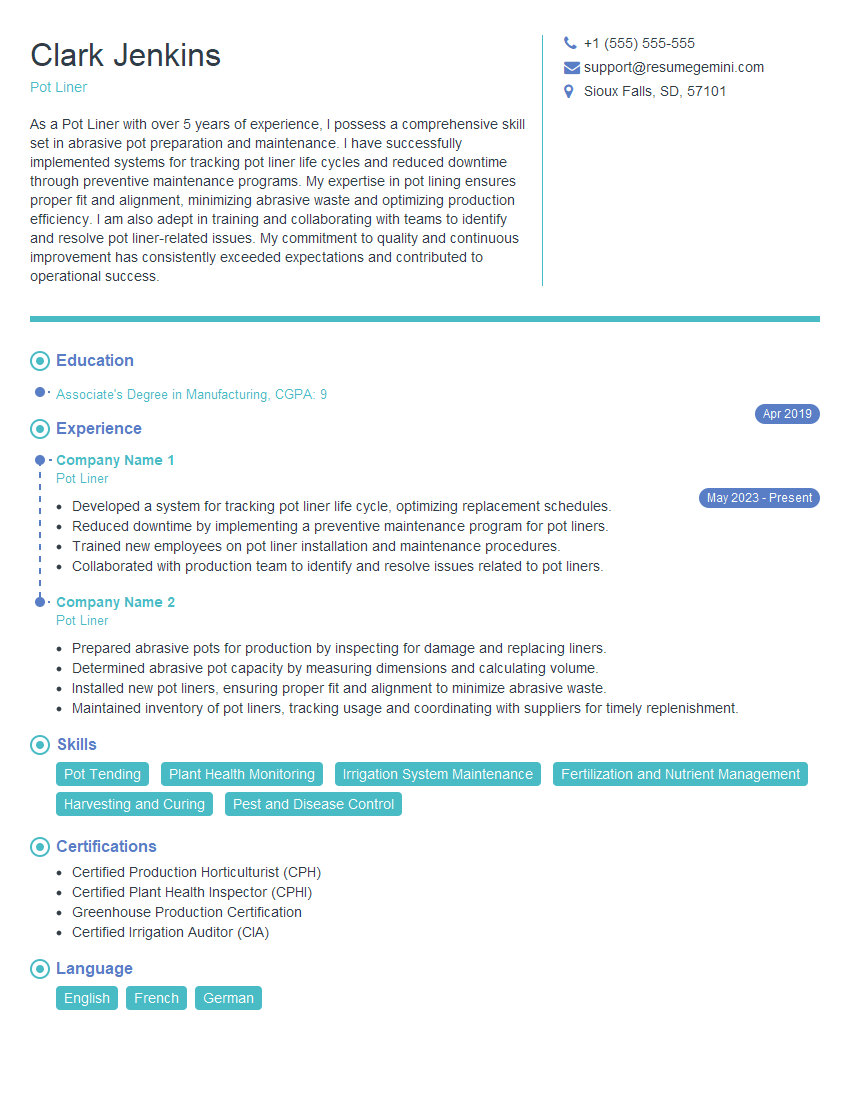

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pot Liner

1. How would you address a crack in a pot liner?

To address a crack in a pot liner, I would follow these steps:

- Inspect the crack to determine its severity and location.

- If the crack is small and superficial, I would use a specialized epoxy or sealant to fill it and create a watertight seal.

- If the crack is more extensive, I would remove the damaged portion of the liner and either replace it with a new section or weld the crack using a high-temperature welding rod.

- After the repair, I would thoroughly inspect and test the liner to ensure its integrity and prevent any leaks.

2. What are the key factors to consider when selecting the appropriate material for a pot liner?

Material selection depends on the following factors:

- Compatibility with the process chemicals: The liner material must be resistant to corrosion, abrasion, and thermal stress.

- Operating temperature: The liner must be able to withstand the temperatures encountered during the process.

- Structural strength: The liner must be able to withstand the mechanical stresses imposed by the process.

Common materials used for pot liners include:

- Stainless steel (304, 316L)

- Hastelloy

- Zirconium

- Tantalum

- Glass-lined steel

3. Describe the welding techniques used in the fabrication of pot liners.

The primary welding techniques used in pot liner fabrication are:

- Gas Tungsten Arc Welding (GTAW): Provides high-quality welds with low distortion. Used for welding thin materials and critical joints.

- Gas Metal Arc Welding (GMAW): A high-productivity welding process suitable for thick materials and larger welds.

- Plasma Arc Welding (PAW): Produces narrow, deep welds with minimal heat input. Used for welding non-ferrous materials and creating precise welds.

4. How do you ensure the quality of welded joints in pot liners?

To ensure the quality of welded joints in pot liners, I follow these practices:

- Proper joint preparation (cleaning, beveling)

- Selection of appropriate welding parameters (amperage, voltage, gas flow)

- Use of qualified welding procedures

- Non-destructive testing (e.g., radiographic inspection, ultrasonic testing) to verify weld integrity

- Adherence to industry standards and codes

5. What are the common causes of pot liner failure and how can they be prevented?

Common causes of pot liner failure include:

- Corrosion: Use corrosion-resistant materials and proper protective coatings.

- Erosion: Install erosion-resistant liners or implement erosion-mitigating measures.

- Abrasion: Use abrasion-resistant materials or protective coatings.

- Thermal stress: Use materials with low coefficients of thermal expansion and design for thermal cycling.

- Mechanical stress: Ensure proper support and handling to avoid overstressing the liner.

6. Describe the process of installing a pot liner in a reactor vessel.

Installing a pot liner in a reactor vessel involves the following steps:

- Preparing the vessel by cleaning and inspecting the surface.

- Installing support brackets or anchors.

- Lifting the pot liner into position using a crane or hoist.

- Aligning and securing the liner using bolts, flanges, or other fastening methods.

- Grouting around the liner to fill any gaps and ensure a tight seal.

- Testing the liner for leaks and proper fit.

7. What are the safety precautions to be observed when working with pot liners?

When working with pot liners, the following safety precautions should be observed:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a hard hat.

- Ensure proper ventilation to avoid exposure to welding fumes.

- Handle and lift heavy liners with caution, using proper lifting techniques.

- Ground electrical equipment properly to prevent electrical accidents.

- Follow established safety procedures and protocols.

8. How do you stay updated on the latest developments and advancements in pot liner technology?

To stay updated on the latest developments and advancements in pot liner technology, I:

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Network with professionals in the field.

- Participate in online forums and discussion groups.

- Collaborate with vendors and manufacturers.

9. Describe a challenging pot liner project you have worked on and the solutions you implemented to overcome the challenges.

In a recent project, we encountered a highly corrosive environment that required a pot liner with exceptional corrosion resistance. We selected a specialized alloy (Hastelloy C-276) and implemented a multi-layer welding technique to ensure maximum corrosion protection. Additionally, we incorporated a cathodic protection system to further enhance the longevity of the liner.

10. How do you handle working under tight deadlines and pressure situations?

When faced with tight deadlines and pressure situations, I prioritize tasks effectively, delegate responsibilities when necessary, and communicate regularly with my team. I remain calm and focused, and I am able to work efficiently under pressure. I also prioritize quality and accuracy in my work, ensuring that deadlines are met without compromising standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pot Liner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pot Liner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pot Liner is responsible for lining up pots, relocating them, and managing the resources in a greenhouse or nursery.

1. Pot Lining and Relocation

The primary responsibility of a Pot Liner is to organize, line up, and re-pot plants in a greenhouse or nursery.

- Lining up pots in designated areas according to instructions or crop plans.

- Relocating pots to appropriate growing areas based on specific requirements, such as light, temperature, or size.

2. Resource Management

Pot Liners are responsible for managing resources within the greenhouse or nursery, ensuring efficient operations and plant health.

- Monitoring and maintaining the cleanliness and organization of work areas, including equipment and tools.

- Ensuring availability of necessary resources, such as pots, soil, and fertilizers, for plant growth and care.

3. Plant Care and Inspection

Pot Liners assist with basic plant care and inspection, contributing to the overall quality of the plants.

- Identifying and reporting any signs of disease or pests to ensure timely intervention.

- Assisting in watering, pruning, or other maintenance tasks as needed to support plant growth.

4. Inventory and Documentation

Pot Liners play a role in maintaining inventory and documentation, contributing to the accuracy and efficiency of operations.

- Maintaining accurate records of plant inventory, including the number, type, and location of plants.

- Assisting with labeling, tagging, or other documentation processes to ensure proper identification and tracking of plants.

Interview Tips

Preparing for an interview is crucial to showcase your skills and make a positive impression. Here are some tips to help you ace your interview for a Pot Liner position:

1. Research the organization and role

Research the greenhouse or nursery you are applying to and the specific Pot Liner role. Understand their mission, values, and the responsibilities associated with the position. This will help you tailor your answers and demonstrate your interest in the organization.

2. Highlight relevant skills and experience

Emphasize your previous experience in plant care, greenhouse operations, or a related field. Showcase your skills in pot lining, plant handling, resource management, and any other relevant areas. Quantify your achievements and provide specific examples to illustrate your capabilities.

3. Practice your answers

Prepare your responses to common interview questions related to your skills, work experience, and availability. Practice delivering your answers clearly and concisely. The more confident and prepared you are, the better you will perform during the interview.

4. Dress professionally and arrive punctually

Make a good impression by dressing professionally and arriving at the interview location on time. Your appearance and punctuality demonstrate your respect for the interviewer and the organization.

5. Be enthusiastic and ask questions

Show your enthusiasm for the role and the organization during the interview. Ask thoughtful questions to learn more about the position, the team, and the company culture. This will demonstrate your genuine interest and engagement.

Next Step:

Now that you’re armed with the knowledge of Pot Liner interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pot Liner positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini