Are you gearing up for an interview for a Pot Lining Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pot Lining Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

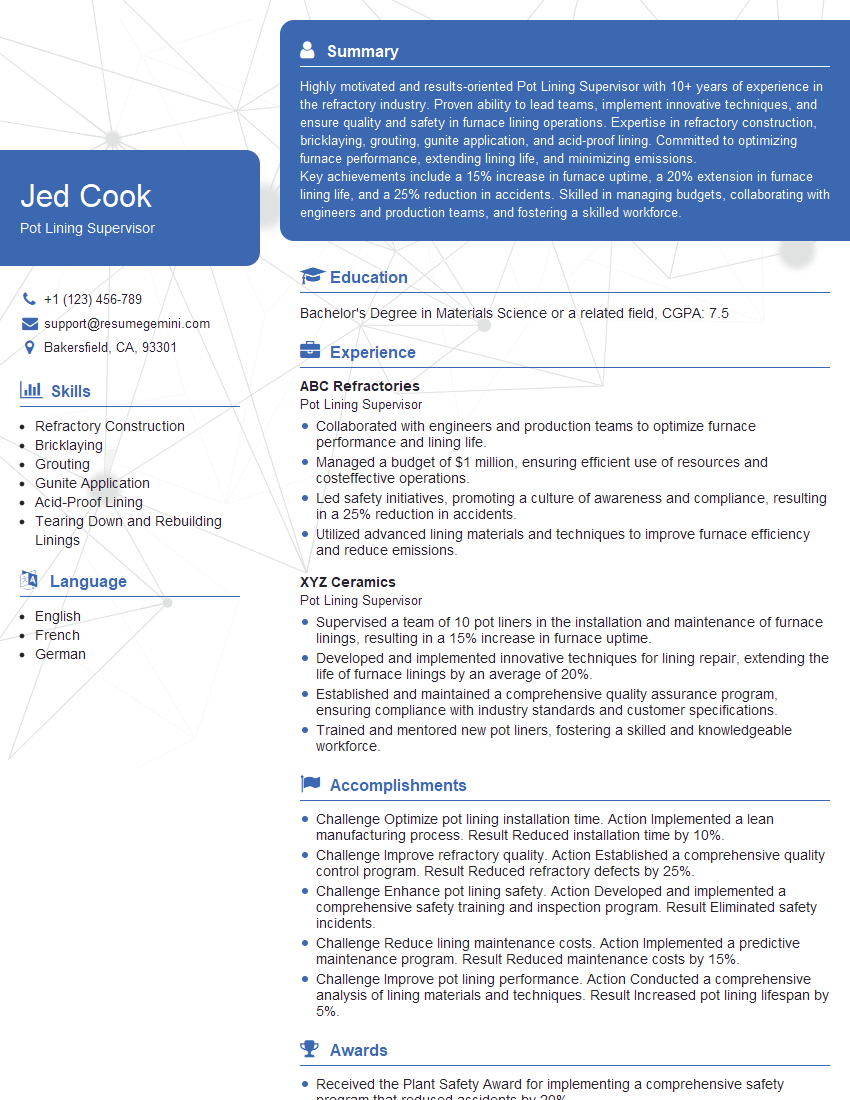

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pot Lining Supervisor

1. Can you explain the process of pot lining?

The pot lining process involves preparing the pot, applying a layer of refractory material, and curing it. It is crucial to accurately follow specifications and use appropriate materials to ensure the pot’s longevity and performance.

2. What are the key factors to consider when selecting refractory materials for pot lining?

Material Properties:

- Chemical composition

- Thermal conductivity

- Coefficient of thermal expansion

Application Requirements:

- Operating temperature

- Mechanical stresses

- Corrosion resistance

3. Describe the methods used for installing refractory materials during pot lining.

There are two primary methods:

- Gunning: Using a specialized gun to spray refractory material onto the pot’s surface.

- Casting: Pouring a molten refractory mixture into the pot and allowing it to solidify.

4. What precautions are necessary during the curing process of the refractory lining?

- Controlled heating and cooling rates

- Adequate ventilation to prevent thermal expansion damage

- Monitoring temperature and moisture levels to prevent cracking or spalling

5. How do you evaluate the quality of a pot lining?

- Visual inspection for any cracks, voids, or delamination

- Non-destructive testing methods (e.g., ultrasonic testing)

- Performance monitoring during furnace operation

6. Describe the common challenges faced during pot lining and how to overcome them.

- Thermal expansion: Use materials with low expansion coefficients and provide for expansion joints.

- Abrasion: Select abrasion-resistant materials or implement wear protection measures.

- Corrosion: Choose corrosion-resistant materials or apply protective coatings.

7. What safety measures are essential during pot lining operations?

- Wearing appropriate protective gear (e.g., gloves, respirators, safety glasses)

- Ensuring adequate ventilation to prevent exposure to harmful fumes

- Following established safety protocols and procedures

8. How do you manage a team of pot lining technicians?

- Clear communication of instructions and expectations

- Regular training and safety briefings

- Monitoring progress and providing feedback

- Ensuring a positive and collaborative work environment

9. Can you provide an example of a successful pot lining project that you have overseen?

Describe the scope of the project, the materials and methods used, and the outcome, highlighting any challenges encountered and how they were resolved.

10. How do you stay up-to-date with advancements in pot lining technologies and best practices?

- Attending industry conferences and workshops

- Reading technical publications and research papers

- Consulting with experts and suppliers

11. What are the key performance indicators (KPIs) you use to measure the effectiveness of pot lining operations?

- Pot lining life

- Furnace efficiency

- Maintenance costs

- Safety record

12. How do you handle unexpected situations or equipment failures during pot lining operations?

Describe your approach to assessing the situation, implementing contingency plans, and minimizing downtime.

13. What are the potential environmental impacts of pot lining operations, and how do you mitigate them?

- Dust and particulate emissions

- Wastewater generation

- Noise pollution

Mitigation measures include:

- Using dust collectors and scrubbers

- Recycling and proper disposal of wastewater

- Implementing noise reduction measures

14. What is your experience with quality control and quality assurance procedures for pot lining operations?

Describe the steps involved in ensuring that pot linings meet specified standards and regulations.

15. How do you coordinate with other departments, such as maintenance and production, to ensure smooth pot lining operations?

- Regular communication and planning meetings

- Clear definition of roles and responsibilities

- Coordination of maintenance schedules to minimize downtime

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pot Lining Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pot Lining Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pot Lining Supervisors are responsible for overseeing the lining of pots used in various industries, such as steel, glass, and chemical manufacturing. They ensure that the lining process meets quality and safety standards, optimizing the performance and longevity of the pots.

1. Managing Pot Lining Operations

Supervising and coordinating the daily activities of pot lining crews, ensuring efficient workflow and adherence to established procedures.

- Planning and scheduling lining projects, allocating resources, and ensuring timely completion.

- Monitoring the progress of lining operations, identifying potential bottlenecks, and implementing corrective measures.

2. Quality Control and Inspection

Ensuring the quality of the pot lining by conducting regular inspections and testing, adhering to industry standards and customer specifications.

- Inspecting the condition of pots, identifying areas requiring maintenance or repair, and initiating appropriate actions.

- Verifying the accuracy of lining thickness and material composition, using specialized equipment and techniques.

3. Safety Management

Prioritizing the safety of workers involved in pot lining operations, implementing safety protocols, and ensuring compliance with regulations.

- Conducting safety briefings, providing training on proper handling of materials and equipment, and enforcing safety policies.

- Monitoring the work environment for potential hazards, implementing risk assessments, and taking corrective actions to mitigate risks.

4. Training and Development

Training and mentoring new and existing crew members, enhancing their skills and knowledge in pot lining techniques and safety practices.

- Developing and delivering training programs, covering theoretical and practical aspects of pot lining operations.

- Assessing the performance of team members, providing feedback, and identifying areas for improvement.

Interview Tips

To ace the interview for a Pot Lining Supervisor position, it is essential to prepare thoroughly and showcase your relevant skills and experience.

1. Research the Industry and Company

Familiarize yourself with the industry trends, the company’s profile, and the specific requirements of the role.

- Visit the company’s website, review industry publications, and attend relevant conferences to gain insights.

- Identify key challenges and opportunities in the pot lining industry and prepare to discuss your potential contributions.

2. Highlight Your Technical Expertise

Demonstrate your in-depth knowledge of pot lining techniques, materials, and equipment.

- Emphasize your experience in various lining methods, such as gunning, vacuum forming, and trowel lining.

- Showcase your ability to troubleshoot and solve technical issues related to pot lining, ensuring optimal performance.

3. Emphasize Your Leadership and Management Skills

Highlight your ability to lead and motivate a team effectively, as well as your experience in managing projects and resources.

- Provide examples of how you have successfully managed teams, resolved conflicts, and facilitated collaboration.

- Discuss your approach to project planning, resource allocation, and performance monitoring.

4. Showcase Your Safety Consciousness

Emphasize your commitment to safety and your experience in implementing and enforcing safety protocols.

- Demonstrate your understanding of industry regulations and best practices related to pot lining safety.

- Share examples of your initiatives to promote a safe work environment, such as conducting safety audits or developing training programs.

5. Prepare for Common Interview Questions

Anticipate and prepare for common interview questions related to pot lining supervision, such as:

- Describe your experience in managing pot lining operations and ensuring quality.

- How do you approach safety management in a pot lining environment?

- Share an example of a challenging pot lining project you successfully completed.

Next Step:

Now that you’re armed with the knowledge of Pot Lining Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pot Lining Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini