Are you gearing up for an interview for a Potato Peeling Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Potato Peeling Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

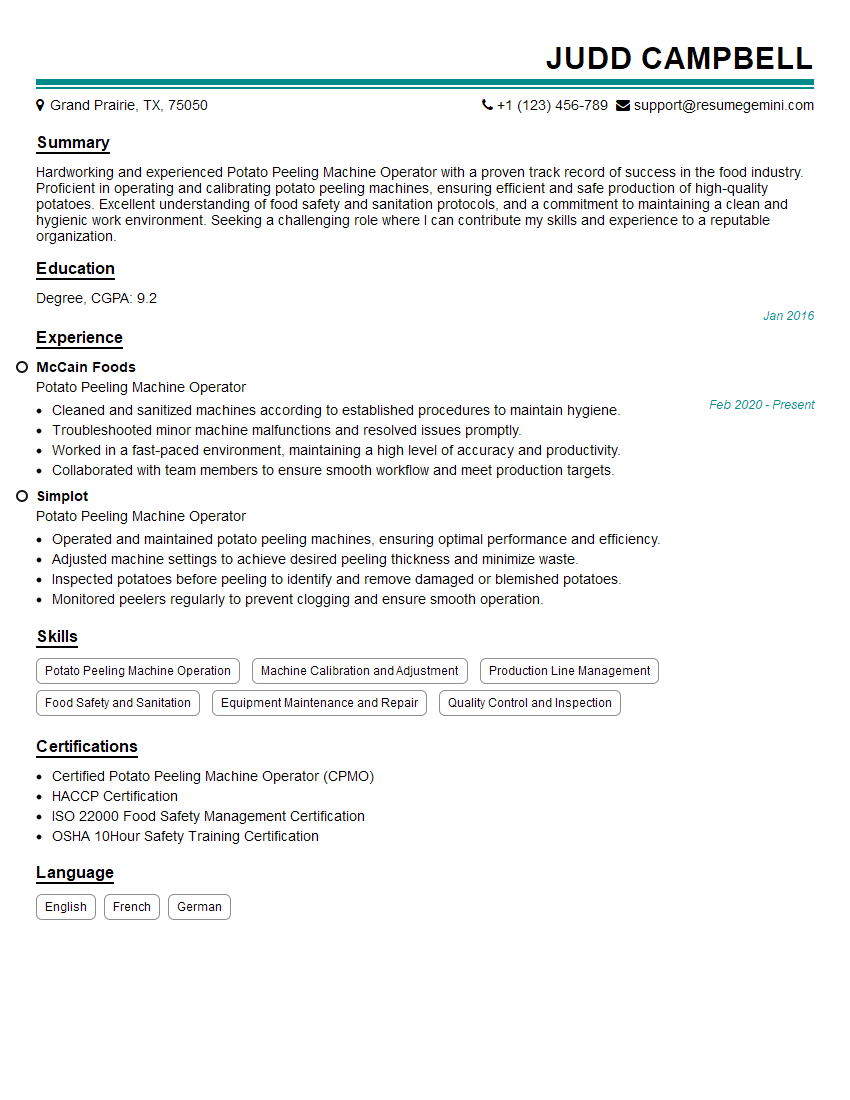

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Potato Peeling Machine Operator

1. Describe the steps involved in operating a potato peeling machine?

- Prepare the machine by checking the water level, abrasive disc, and conveyor belt.

- Set the appropriate peel thickness and water flow rate.

- Load the potatoes into the hopper and start the machine.

- Monitor the peeling process and adjust settings as needed.

- Unload the peeled potatoes and inspect them for quality.

- Clean and sanitize the machine after use.

2. What safety precautions should be followed when operating a potato peeling machine?

- Wear appropriate safety gear, including gloves, eye protection, and a hairnet.

- Keep hands and loose clothing away from moving parts.

- Never operate the machine if it is damaged or malfunctioning.

- Follow all manufacturer’s instructions and safety protocols.

- Report any accidents or injuries immediately.

3. How do you determine the correct peel thickness for different types of potatoes?

- Consider the intended use of the potatoes (e.g., for mashing, roasting, or slicing).

- Thicker peels are suitable for potatoes that will be roasted or baked.

- Thinner peels are preferred for potatoes that will be mashed or sliced.

- Adjust the machine settings accordingly and conduct test peels to ensure the desired thickness.

4. Explain the importance of maintaining the abrasive disc in a potato peeling machine?

- A sharp abrasive disc ensures efficient peeling and reduces potato waste.

- Regular maintenance and replacement of the disc prevent damage to the potatoes.

- A dull disc can cause uneven peeling, reduce yield, and increase energy consumption.

- Inspect the disc regularly for wear and tear and sharpen or replace it as per manufacturer’s recommendations.

5. Describe the role of water in a potato peeling machine and how it affects the peeling process?

- Water helps lubricate the peeling process and prevent overheating.

- Adequate water flow ensures smooth peeling and reduces bruising.

- Excessive water can lead to potato breakage and yield loss.

- Adjust the water flow rate based on the type of potatoes and the desired peel thickness.

6. Explain the procedure for cleaning and sanitizing a potato peeling machine?

- Disconnect the machine from the power supply.

- Remove any remaining potatoes and debris.

- Use a mild detergent solution to clean all surfaces, paying attention to the hopper, conveyor belt, and abrasive disc.

- Rinse thoroughly with clean water.

- Sanitize using a food-grade sanitizer.

- Dry the machine completely before storing.

7. How can you troubleshoot common problems encountered with potato peeling machines?

- Identify the problem (e.g., uneven peeling, potato breakage, machine vibration).

- Check the abrasive disc for wear or damage.

- Adjust the peel thickness, water flow rate, or conveyor belt speed.

- Inspect electrical connections and ensure the machine is properly grounded.

- Refer to the manufacturer’s instructions or consult with a qualified technician for complex issues.

8. Describe the different types of potatoes and their suitability for machine peeling?

- Firm potatoes (e.g., russet, Yukon Gold): Suitable for machine peeling as they hold their shape well.

- Soft potatoes (e.g., red potatoes, fingerling potatoes): May break easily during machine peeling and are better suited for hand-peeling.

- New potatoes: Have thin skins and can be peeled using a lower peel thickness setting.

- Organic potatoes: May have bumps or irregularities that require hand-peeling or careful machine handling.

9. Explain how to minimize potato waste during the machine peeling process?

- Choose potatoes of uniform size and shape.

- Adjust the peel thickness to remove only the necessary amount of skin.

- Use a sharp abrasive disc to reduce breakage.

- Properly calibrate the machine settings.

- Monitor the peeling process and make adjustments as needed.

10. Discuss the importance of maintaining a clean and organized work area around a potato peeling machine?

- A clean workspace prevents the spread of bacteria and contamination.

- Reduces the risk of accidents and injuries.

- Improves work efficiency by making tools and materials easily accessible.

- Creates a professional and positive work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Potato Peeling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Potato Peeling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Potato Peeling Machine Operator is responsible for operating and maintaining potato peeling machines in a food processing or manufacturing facility. Their primary responsibilities include:

1. Operating Potato Peeling Machines

The operator is responsible for setting up, operating, and monitoring potato peeling machines. This includes loading potatoes into the machine, adjusting settings for peeling thickness, and monitoring the machine’s performance to ensure optimal peeling results.

2. Maintaining Potato Peeling Machines

Regular maintenance is crucial to ensure the efficient operation of the potato peeling machines. The operator is responsible for cleaning the machines, replacing worn or damaged parts, and performing minor repairs as needed.

3. Quality Control

The operator is responsible for visually inspecting peeled potatoes to ensure they meet quality standards. This includes checking for any remaining skin or blemishes, as well as ensuring the potatoes are the desired size and shape.

4. Safety and Hygiene

The operator must adhere to all safety and hygiene regulations in the workplace. This includes wearing appropriate protective gear, maintaining a clean and sanitary work area, and following established procedures for handling food products.

Interview Tips

To ace an interview for a Potato Peeling Machine Operator position, candidates should thoroughly prepare and demonstrate their skills and knowledge. Here are some tips to help candidates prepare:

1. Research the Company and Industry

Candidates should research the company they are applying to, its products or services, and the industry in which it operates. This knowledge will help them understand the company’s needs and how their skills and experience align with the role.

2. Practice Answering Common Interview Questions

Candidates should practice answering common interview questions, such as: “Tell me about your experience operating potato peeling machines?” and “How do you ensure the quality of peeled potatoes?” By rehearsing their answers, they can deliver clear and concise responses that highlight their strengths.

3. Highlight Transferable Skills

Even if candidates do not have direct experience as a Potato Peeling Machine Operator, they may possess transferable skills that are valuable in this role. For example, candidates with experience in other food processing or manufacturing settings can emphasize their understanding of food safety and hygiene regulations.

4. Be Enthusiastic and Professional

Candidates should demonstrate their enthusiasm for the position and the food industry. They should also maintain a professional demeanor throughout the interview, dress appropriately, and arrive on time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Potato Peeling Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Potato Peeling Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.