Feeling lost in a sea of interview questions? Landed that dream interview for Potter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Potter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

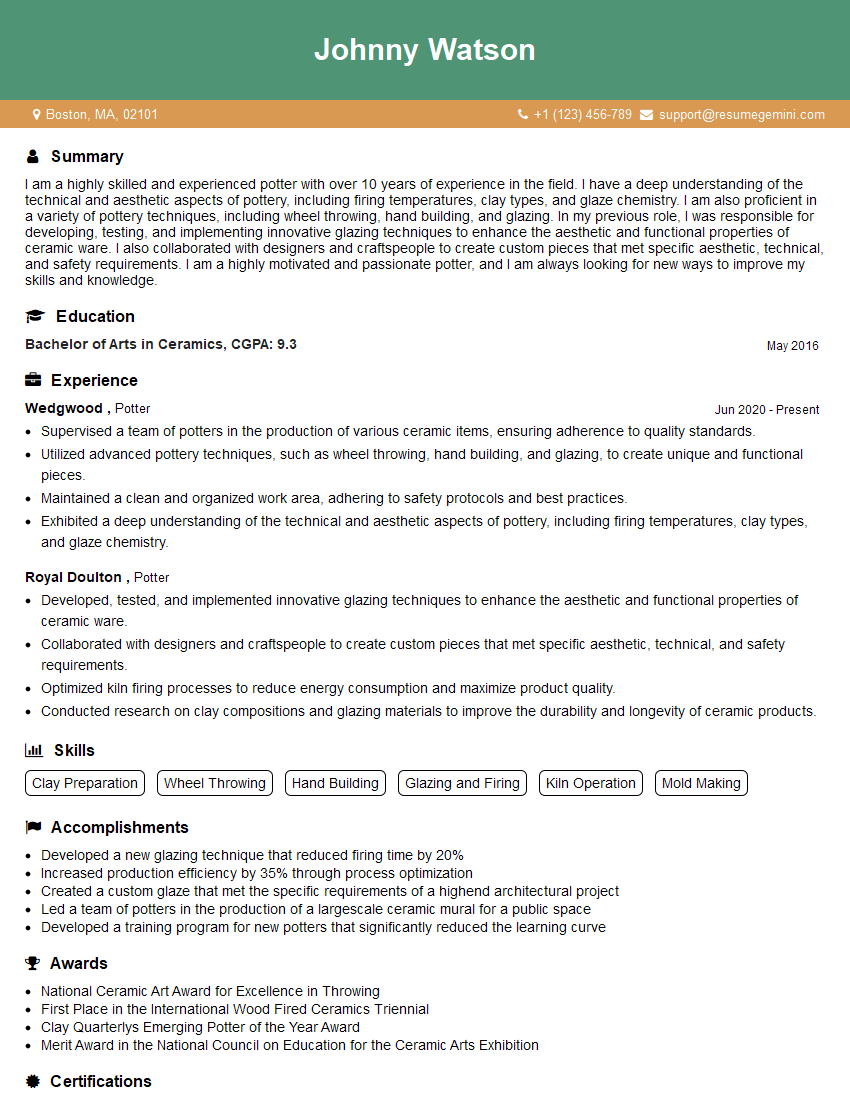

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Potter

1. What is the difference between a glaze and an underglaze?

– Glazes are a type of transparent or opaque coating applied to the surface of a ceramic piece before firing, which melts at high temperatures and forms a smooth, glossy finish. – Underglazes are applied to the unfired clay body before the glaze and are absorbed into the clay, creating a more permanent and durable decoration.

2. What are the different types of kilns used in pottery?

Electric Kilns:

- Cone firing: Uses numbered cones that bend or melt at specific temperatures to indicate when the kiln has reached the desired firing temperature.

- Programmable kilns: Allow for precise temperature control and firing schedules to be programmed.

Gas Kilns:

- Natural gas firing: Uses natural gas as the fuel source, providing a more reducing atmosphere that can produce unique color effects.

- Propane firing: Uses propane as the fuel source, which is more convenient and controllable than natural gas.

Wood-Fired Kilns:

- Anagama kilns: Traditional Japanese kilns that are fired continuously for several days, creating unique ash and flame patterns on the pottery.

- Bourry Box kilns: Modern kilns that use a combination of wood and gas to achieve high temperatures with precise control.

3. What are the key factors that influence the color and texture of a fired ceramic piece?

– Clay Body: The composition and firing temperature of the clay body can significantly impact the color and texture. – Glaze: The chemical composition and thickness of the glaze can determine the color, glossiness, and opacity of the finished piece. – Firing Atmosphere: The oxygen levels in the kiln during firing (oxidizing or reducing) can influence the color development and surface texture. – Temperature: The firing temperature and duration can affect the color, density, and strength of the ceramic piece. – Additives: Metal oxides, stains, and other additives can be incorporated into the clay or glaze to achieve specific colors and effects.

4. Describe the process of throwing a pot on a potter’s wheel.

- Prepare the clay: Wedge the clay to remove air bubbles and ensure even moisture distribution.

- Center the clay on the wheel: Place a ball of clay on the wheel and center it using your hands and a centering tool.

- Open the clay: Use your thumbs to create a hole in the center of the clay, gradually widening it to form the base.

- Raise the walls: Use your fingers and palms to pull up the clay walls, controlling the thickness and shape.

- Shape the pot: Use tools such as ribs and sponges to refine the shape, smooth the surfaces, and create details.

- Trim and finish: Once the pot is thrown, use a trimming tool to remove excess clay and refine the shape and foot.

5. What are the main differences between earthenware, stoneware, and porcelain?

- Earthenware: Low-firing clay body (900-1100°C), porous, and typically used for decorative or non-food-safe items.

- Stoneware: Mid-firing clay body (1150-1300°C), denser, more durable, and can be glazed to make it food-safe.

- Porcelain: High-firing clay body (1250-1450°C), very dense, translucent, and often used for fine tableware, tiles, and electrical insulators.

6. Explain the concept of bisque firing and its importance in the pottery process.

– Bisque firing is the first firing of a ceramic piece, typically at a lower temperature (900-1000°C) than the final glaze firing. – It transforms the clay into a porous but durable form, preparing it to receive the glaze. – Bisque firing removes any remaining moisture from the clay, making it less prone to cracking or warping during the glaze firing.

7. Describe the different methods of decorating pottery surfaces.

- Glazing: Applying a liquid or powdered glaze to the surface of the ceramic piece, which melts and forms a glossy or matte finish during firing.

- Underglazing: Applying colored pigments or stains to the unfired clay body before glazing, creating durable and permanent designs.

- Sgraffito: Scratching or carving designs into the surface of the clay body before firing, revealing the underlying clay color.

- Slip trailing: Using a liquid clay slip (a mixture of clay and water) to create designs or patterns on the surface of the ceramic piece.

8. What are the safety precautions that should be taken when working with pottery materials and equipment?

- Wear appropriate protective gear (mask, gloves, eye protection) when handling clay dust or glazes containing hazardous materials.

- Ensure proper ventilation in the studio to prevent inhalation of harmful fumes.

- Store chemicals and glazes safely, away from food and drink.

- Be cautious when using sharp tools and machinery, and always follow proper operating procedures.

- Handle hot kilns and pottery with care to prevent burns.

9. What are the essential qualities of a successful potter?

- Artistic ability and creativity

- Technical skills and knowledge of materials and techniques

- Attention to detail and precision

- Patience and perseverance

- Strong work ethic and willingness to experiment

- Understanding of the science and chemistry of ceramics

- Ability to work independently and as part of a team

10. Describe your approach to problem-solving when working with challenging pottery projects.

– Identify the problem: Clearly define the challenge and gather necessary information. – Research and explore solutions: Consult with experienced potters or research online resources to find potential solutions. – Experiment and test: Implement different solutions on small test pieces to evaluate their effectiveness. – Analyze results and adjust: Observe the outcomes of the experiments and make adjustments as needed to refine the solution. – Implement and evaluate: Apply the best solution to the main project and monitor its effectiveness, making further adjustments if necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Potter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Potter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A potter is a skilled artisan who specializes in creating functional and decorative items from clay. As a potter, you will be responsible for shaping, glazing, and firing clay to produce a variety of products, from tableware to vases to sculptures.

1. Prepare and Blend Clay

Before you can begin shaping clay, you must prepare and blend it to ensure it is the right consistency and has the desired properties. This involves mixing different types of clay together, adding water, and kneading the clay until it is smooth and pliable.

2. Shape and Form Clay

Once the clay is prepared, you can begin shaping and forming it into the desired objects. This can be done using a variety of techniques, such as hand-building, wheel throwing, and slip casting. You may also use molds or templates to create specific shapes or designs.

3. Glaze and Decorate Clay

Once the clay objects have been shaped and formed, they can be glazed and decorated. Glazing involves applying a liquid glass coating to the clay, which is then fired in a kiln to create a shiny, protective surface. You may also use underglazes, slips, or other decorative techniques to add color and design to your work.

4. Fire Clay

The final step in the pottery process is firing the clay in a kiln. This process involves heating the clay to a high temperature, which causes the clay to harden and become durable. You must carefully control the temperature and duration of the firing process to ensure that the clay objects are properly vitrified and do not crack or warp.

5. Maintain Equipment and Workspace

In addition to your creative responsibilities, you will also be responsible for maintaining your equipment and workspace. This includes cleaning and maintaining your kiln, pottery wheels, and other tools, as well as keeping your work area organized and free of debris.

Interview Tips

Preparing for an interview for a pottery position can be daunting, but by following these tips, you can increase your chances of success:

1. Research the Company and Position

Before you go to your interview, take the time to research the company and the specific pottery position you are applying for. This will help you understand the company’s culture, values, and goals, and will give you a better idea of what the interviewer is looking for in a candidate.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take the time to practice your answers to these questions so that you can deliver them confidently and clearly.

3. Showcase Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the pottery position. This includes your technical skills, such as your ability to shape, glaze, and fire clay, as well as your artistic skills, such as your ability to create unique and beautiful pieces.

4. Be Enthusiastic and Passionate

Pottery is a craft that requires passion and enthusiasm. In your interview, be sure to show the interviewer that you are genuinely passionate about pottery and that you are eager to learn and grow as a potter.

5. Be Prepared to Ask Questions

At the end of your interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position, and to show the interviewer that you are engaged and interested.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Potter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.