Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pottery Kiln Builder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

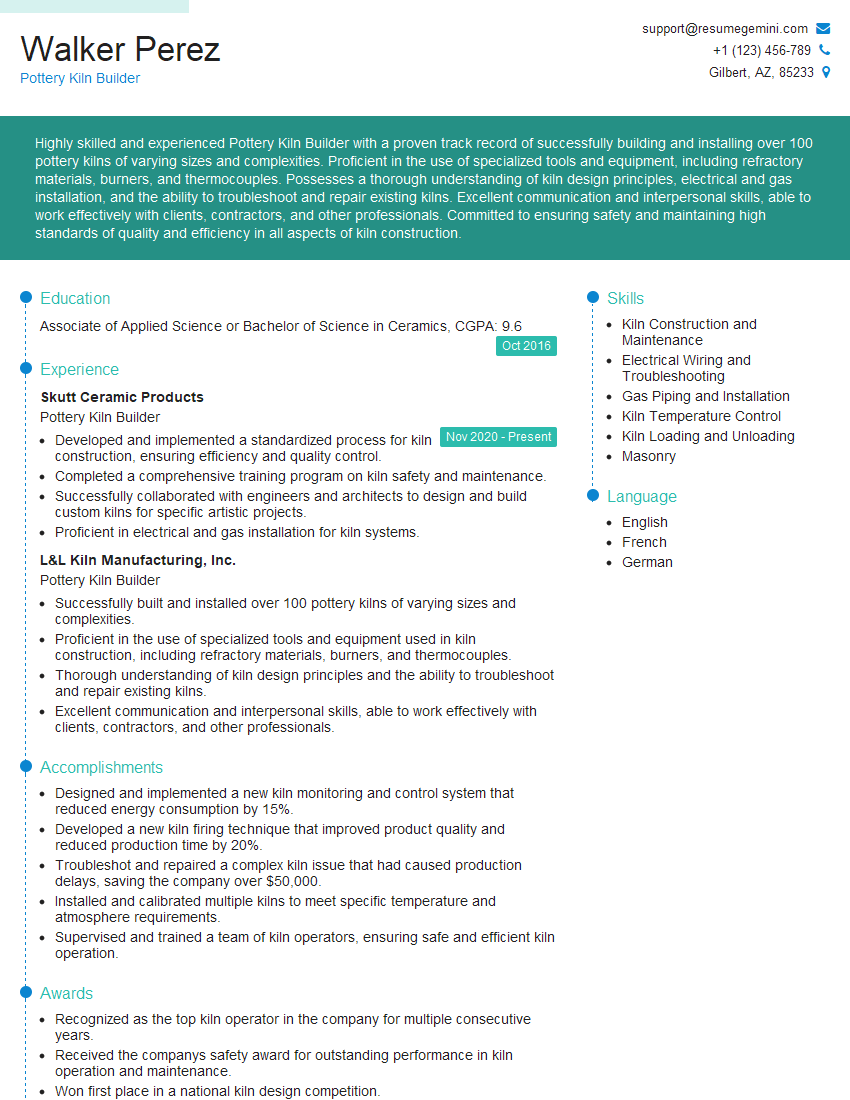

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pottery Kiln Builder

1. Discuss the different types of pottery kilns and their applications?

- Electric kilns: Use electricity to heat up and are popular for their ease of use and precise temperature control. They are suitable for firing a wide range of clay bodies and glazes.

- Gas kilns: Use natural gas or propane as a fuel source and produce higher temperatures than electric kilns. They are often used for firing large pieces or for achieving specific effects in glazes.

- Wood-fired kilns: Use wood as a fuel source and create a unique and unpredictable atmosphere in the kiln. They are often used by artists who want to achieve specific aesthetic effects or explore experimental firing techniques.

2. Explain the process of designing and building a pottery kiln?

Kiln design

- Determine the size and shape of the kiln based on the work to be fired.

- Select the type of kiln (electric, gas, or wood-fired) based on the desired firing temperature and atmosphere.

- Design the kiln’s interior, including the shelves and walls, to ensure even heat distribution.

Kiln construction

- Gather the necessary materials, such as firebricks, insulation, and kiln elements.

- Build the kiln’s frame and walls, ensuring proper insulation and support.

- Install the kiln elements and wiring, ensuring proper electrical connections.

3. What are the safety considerations when operating a pottery kiln?

- Electrical safety: Ensure that the kiln is properly grounded and that all electrical connections are secure.

- Fire safety: Keep the kiln area clear of flammable materials and have a fire extinguisher readily available.

- Ventilation: Ensure that the kiln is properly ventilated to remove harmful fumes and gases.

- Personal protective equipment: Wear appropriate personal protective equipment, such as gloves, safety glasses, and a respirator, when operating the kiln.

4. How do you troubleshoot common problems that may arise during kiln firing?

- Uneven firing: Check for obstructions in the kiln, ensure proper shelf placement, and adjust the firing schedule if necessary.

- Overfiring: Reduce the firing temperature or shorten the firing time.

- Underfiring: Extend the firing time or increase the firing temperature.

- Cracking: Use a slower firing schedule, avoid rapid temperature changes, and ensure that the clay body is properly prepared.

5. What are the different types of glazes used in pottery and their properties?

- Clear glazes: Transparent glazes that allow the color of the clay body to show through.

- Opaque glazes: Glazes that are not transparent and create a solid color on the surface of the pottery.

- Glossy glazes: Glazes that produce a shiny and reflective surface.

- Matte glazes: Glazes that produce a dull and non-reflective surface.

6. How do you calculate the firing schedule for a specific clay body and glaze combination?

- Determine the optimal firing temperature for the clay body and glaze.

- Create a schedule that gradually increases the temperature to the desired peak temperature.

- Include a hold period at the peak temperature to ensure complete vitrification.

- Gradually cool the kiln at a controlled rate to prevent thermal shock.

7. What are the key factors that affect the quality of the fired pottery?

- Clay body selection: The composition and properties of the clay body influence its firing behavior and the final appearance of the pottery.

- Glaze application: The thickness and evenness of the glaze application affect the finished surface.

- Firing schedule: The temperature, duration, and rate of the firing process determine the vitrification, color, and texture of the pottery.

- Kiln atmosphere: The presence or absence of oxygen in the kiln during firing can affect the oxidation or reduction of the clay body and glaze.

8. How do you maintain and calibrate a pottery kiln?

- Regular cleaning: Remove any debris or glaze buildup to ensure proper heat distribution.

- Element replacement: Replace worn-out or damaged kiln elements to maintain optimal heating performance.

- Temperature calibration: Use a thermocouple or pyrometer to calibrate the kiln’s temperature controller to ensure accurate firing.

- Insulation inspection: Check the insulation for any damage or deterioration to maintain thermal efficiency.

9. What are the latest advancements in pottery kiln technology?

- Computerized controllers: Advanced controllers provide precise temperature control and allow for programmable firing schedules.

- Energy-efficient designs: Kilns are designed to minimize heat loss and reduce energy consumption.

- Digital glaze testing: Digital glaze testing systems analyze glazes to predict their behavior and improve glaze development.

- 3D printing: 3D printing technology is used to create custom kiln shelves and other components.

10. Describe a challenging kiln firing experience and how you overcame it?

- Briefly describe the challenge encountered, such as uneven firing, glaze defects, or kiln malfunction.

- Explain the steps taken to troubleshoot the issue, including research, experimentation, and consultation with experts.

- Discuss the solution implemented and the positive outcome achieved, emphasizing the skills and knowledge applied.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pottery Kiln Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pottery Kiln Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pottery Kiln Builder is responsible for constructing, repairing, and maintaining kilns used for firing pottery. This role requires a combination of specialized knowledge and practical skills in various aspects of kiln building and operation.

1. Kiln Construction

The primary responsibility of a Pottery Kiln Builder is to construct new kilns. This involves:

- Designing and laying out the kiln structure based on specific requirements

- Selecting and sourcing appropriate materials, such as bricks, refractory cement, and insulation

- Building the kiln according to the design specifications, ensuring structural integrity and safety

2. Kiln Repair and Maintenance

Kiln Builders also perform repairs and maintenance on existing kilns. This includes:

- Inspecting kilns regularly to identify any damage or issues

- Repairing or replacing damaged components, such as bricks, burners, or thermocouples

- Performing routine maintenance tasks, such as cleaning the kiln, adjusting burners, and calibrating temperature controls

3. Kiln Operation

In addition to construction and maintenance, Pottery Kiln Builders may also be involved in operating kilns for firing pottery. This involves:

- Loading and unloading pottery ware into the kiln

- Monitoring and adjusting the kiln’s temperature and atmosphere during firing

- Troubleshooting and resolving any issues that arise during the firing process

4. Safety and Compliance

Pottery Kiln Builders must adhere to strict safety regulations and industry standards. This includes:

- Ensuring that kilns are built and operated safely and in accordance with applicable codes

- Using appropriate personal protective equipment (PPE) when working with kilns

- Maintaining a clean and organized work environment

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are a few tips for candidates applying for a Pottery Kiln Builder position:

1. Highlight Your Skills and Experience

In your resume and during the interview, emphasize your relevant skills and experience. Showcase your knowledge of kiln construction, repair, and operation.

2. Research the Company and Industry

Make sure you have a good understanding of the company you’re applying to and the pottery industry as a whole. This will help you tailor your answers to the interviewer’s questions and demonstrate your interest.

3. Practice Common Interview Questions

Prepare for common interview questions by researching online or asking a friend or family member to practice with you. Some common questions include:

- Tell me about your experience building pottery kilns.

- What are the most important safety considerations when working with kilns?

- How would you troubleshoot a kiln that is not firing correctly?

- What are the latest trends in kiln design and technology?

- Why are you interested in working for this company?

4. Ask Thoughtful Questions

Prepare a few thoughtful questions to ask the interviewer at the end of the interview. This shows that you’re engaged and interested in the position. Some good questions to ask include:

- What are the biggest challenges facing the pottery industry today?

- What are the company’s plans for growth and expansion?

- What is the company culture like?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pottery Kiln Builder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!