Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pouch Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

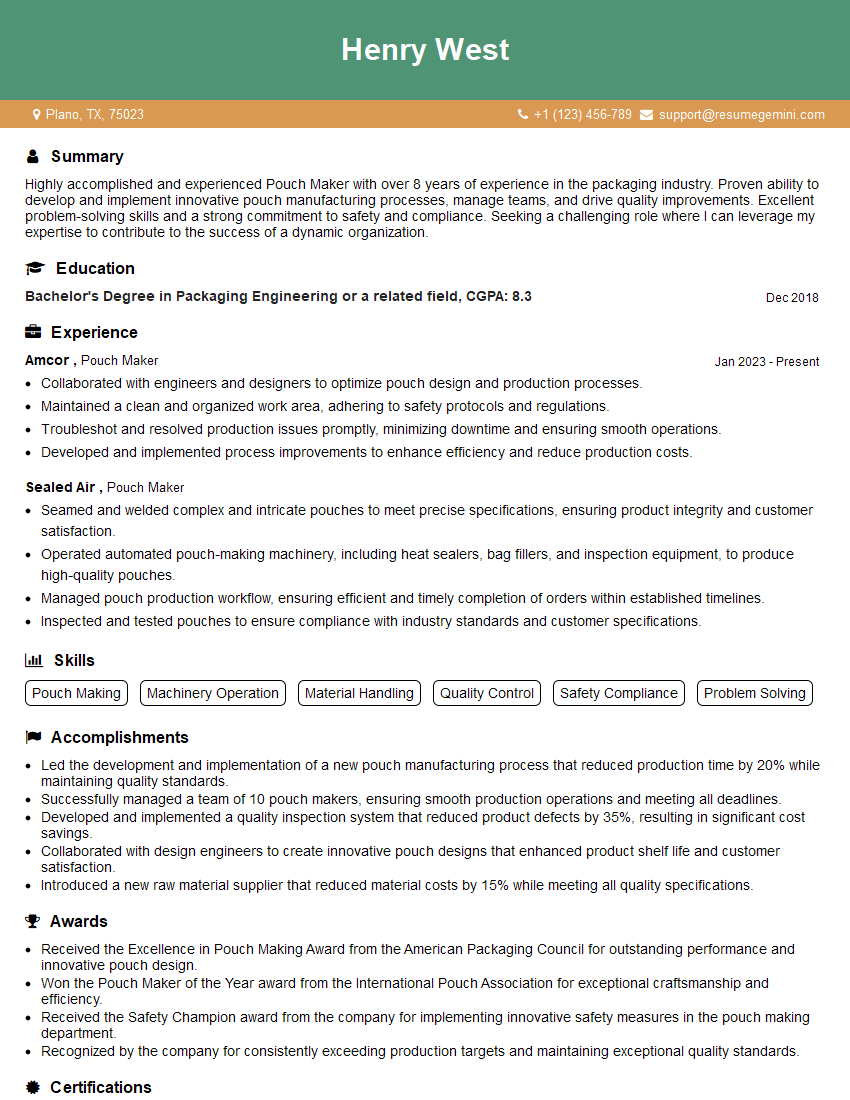

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pouch Maker

1. Describe the key steps involved in the pouch-making process?

In the pouch-making process, the following key steps are involved:

- Film Preparation: The raw film material is inspected and prepared for the production process.

- Extrusion and Lamination: The film is extruded and laminated to create the desired thickness and properties.

- Printing: The necessary designs, logos, and information are printed on the film.

- Cutting and Shaping: The film is cut and shaped into the pouch’s desired size and shape.

- Folding and Sealing: The cut pieces are folded and sealed to form the pouch structure.

- Inspection and Packaging: The finished pouches are inspected for quality and packaged for distribution.

2. Which raw materials are typically used in pouch making?

The primary raw materials used in pouch making include:

- Polyethylene (PE): Provides flexibility, moisture resistance, and cost-effectiveness.

- Polypropylene (PP): Offers high strength, clarity, and heat resistance.

- Polyester (PET): Ensures high barrier properties, durability, and recyclability.

- Aluminum Foil: Used for superior gas and moisture barrier in flexible packaging.

- Paper: Provides biodegradability, compostability, and sustainability options.

3. What factors influence the choice of material for pouch making?

The selection of materials for pouch making is influenced by various factors, including:

- Product Requirements: The type of product being packaged and its specific properties.

- Shelf Life and Barrier Properties: The desired shelf life and level of protection against oxygen, moisture, and other environmental factors.

- Machinability: The compatibility of the material with the pouch-making machinery.

- Cost and Availability: The economic considerations and availability of the raw materials.

- Sustainability and Environmental Concerns: The eco-friendly nature and recyclability of the materials.

4. Describe the different types of pouch sealing methods?

In pouch making, the following sealing methods are commonly used:

- Heat Sealing: The most common method, using heat to bond two layers of film together.

- Impulse Sealing: A variant of heat sealing, applying heat for a short duration through electrical impulses.

- Ultrasonic Sealing: Utilizes high-frequency sound waves to create a strong and airtight seal.

- Radio Frequency (RF) Sealing: Employs electromagnetic energy to generate heat and weld the film layers.

- Cold Sealing: Adhesion-based sealing, where pressure-sensitive adhesives are used to bond the film.

5. How do you ensure the quality of the finished pouches?

To maintain quality standards in pouch making, the following measures are crucial:

- Raw Material Inspection: Checking the quality and consistency of incoming raw materials.

- Process Control: Monitoring and adjusting process parameters throughout production to meet specifications.

- In-Process Inspection: Regularly inspecting pouches at various production stages to identify defects.

- Final Inspection: Thoroughly examining finished pouches for any imperfections or non-conformities.

- Testing: Conducting physical and performance tests to ensure the pouches meet required standards.

6. What is the role of printing in pouch making?

Printing plays a vital role in pouch making by:

- Providing Product Information: Displaying essential details such as product name, ingredients, and nutritional facts.

- Brand Building: Featuring logos, designs, and marketing messages to enhance brand recognition.

- Legal Compliance: Including mandatory information required by regulatory authorities.

- Anti-Counterfeiting: Incorporating unique printing techniques to prevent counterfeiting and protect brand identity.

- Consumer Engagement: Creating visually appealing and informative pouches to attract and engage customers.

7. Describe the different printing techniques used in pouch making?

Common printing techniques in pouch making include:

- Flexographic Printing: Utilizes flexible printing plates to transfer ink onto the film.

- Gravure Printing: Employs engraved cylinders to transfer ink, resulting in high-quality prints.

- Digital Printing: Uses computer-controlled inkjet technology for precise and variable printing.

- Screen Printing: Involves forcing ink through a mesh screen onto the film.

- Lithographic Printing: Transfers ink from a flat printing plate to the film using a water-based process.

8. What is the importance of pouch design in the packaging industry?

Pouch design plays a crucial role in the packaging industry due to its:

- Functionality: Ensuring the pouch meets the functional requirements of the product, such as protection and ease of use.

- Marketing and Sales: Creating visually appealing and informative designs to attract consumers and promote sales.

- Sustainability: Incorporating eco-friendly materials and designs to reduce environmental impact.

- Convenience: Designing pouches that are easy to open, use, and dispose of.

- Innovation: Exploring new and innovative designs to differentiate products and enhance consumer experience.

9. What are the current trends and advancements in pouch-making technology?

Current trends and advancements in pouch-making technology include:

- Sustainable Packaging: Focus on using recyclable, biodegradable, and compostable materials.

- Advanced Printing Techniques: Integration of digital and high-resolution printing technologies for enhanced visuals.

- Smart Packaging: Incorporating sensors, QR codes, and interactive elements into pouches.

- Modified Atmosphere Packaging (MAP): Controlling the atmosphere inside pouches to extend product shelf life.

- Automated and Efficient Production: Adoption of automated machinery and process optimization to improve efficiency and reduce costs.

10. How do you stay updated with the latest advancements and best practices in the pouch-making industry?

To stay current with the latest advancements and best practices in the pouch-making industry, I follow these strategies:

- Industry Events and Exhibitions: Attending trade shows and industry events to learn about new technologies and trends.

- Professional Development: Participating in webinars, workshops, and training programs to expand my knowledge.

- Technical Publications and Journals: Reading industry-specific publications, journals, and online resources.

- Networking and Collaboration: Engaging with industry professionals, attending conferences, and exchanging ideas.

- Research and Development: Actively seeking out and exploring innovative solutions and advancements in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pouch Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pouch Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pouch Makers are highly skilled individuals responsible for producing pouches used in a variety of industries, including food, medical, and consumer products. They operate specialized machinery to convert raw materials into finished pouches, ensuring adherence to quality standards.

1. Pouch Production

The primary responsibility of Pouch Makers is operating machinery to produce pouches. This involves:

- Setting up and calibrating pouch-making machines

- Feeding raw materials (films, foils, etc.) into the machines

- Monitoring the production process and making adjustments as needed

2. Quality Control

Pouch Makers play a crucial role in maintaining product quality by adhering to strict manufacturing standards. Their responsibilities include:

- Inspecting pouches for defects and imperfections

- Conducting laboratory tests to ensure product compliance

- Maintaining a clean and sanitary work environment

3. Equipment Maintenance

To ensure optimal production, Pouch Makers are responsible for maintaining and troubleshooting equipment. This involves:

- Performing routine maintenance and cleaning tasks

- Identifying and resolving machine malfunctions

- Collaborating with technicians for major repairs

4. Process Optimization

Pouch Makers are actively involved in improving production processes. Their responsibilities include:

- Identifying areas for efficiency improvements

- Conducting time and motion studies

- Making recommendations for process enhancements

Interview Tips

To ace an interview for a Pouch Maker position, candidates should:

1. Research the Company and Industry

Demonstrate knowledge of the company’s products and manufacturing processes, as well as industry trends and developments.

- Visit the company website and read industry publications.

- Prepare questions about the company’s production capabilities and quality standards.

2. Practice Technical Skills

Be prepared to discuss your proficiency in pouch-making equipment operation, including machine setup, operation, and maintenance.

- Review the job description and identify specific skills required.

- If possible, practice on similar equipment or seek hands-on experience.

3. Highlight Quality Control and Process Improvement Skills

Emphasize your commitment to product quality and process optimization. Provide examples of your attention to detail and ability to identify and resolve production issues.

- Describe your experience in quality control procedures, such as inspection and testing.

- Discuss instances where you identified process inefficiencies and implemented improvements.

4. Express Interest in Professional Development

Show your willingness to learn new technologies and improve your skills. Discuss your interest in industry training and certification programs.

- Mention any relevant certifications or training you have completed.

- Ask about opportunities for professional growth within the company.

Next Step:

Now that you’re armed with the knowledge of Pouch Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pouch Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini